MAINTENANCE

PRE-INKING A NEW INK ROLL

When you are ready to begin printing, you must first install an ink roll which has been properly

Ink Cartridges.

Warning:

A dry XF Neoprene ink roll has the same characteristics as a sponge with the capacity to absorb approximately

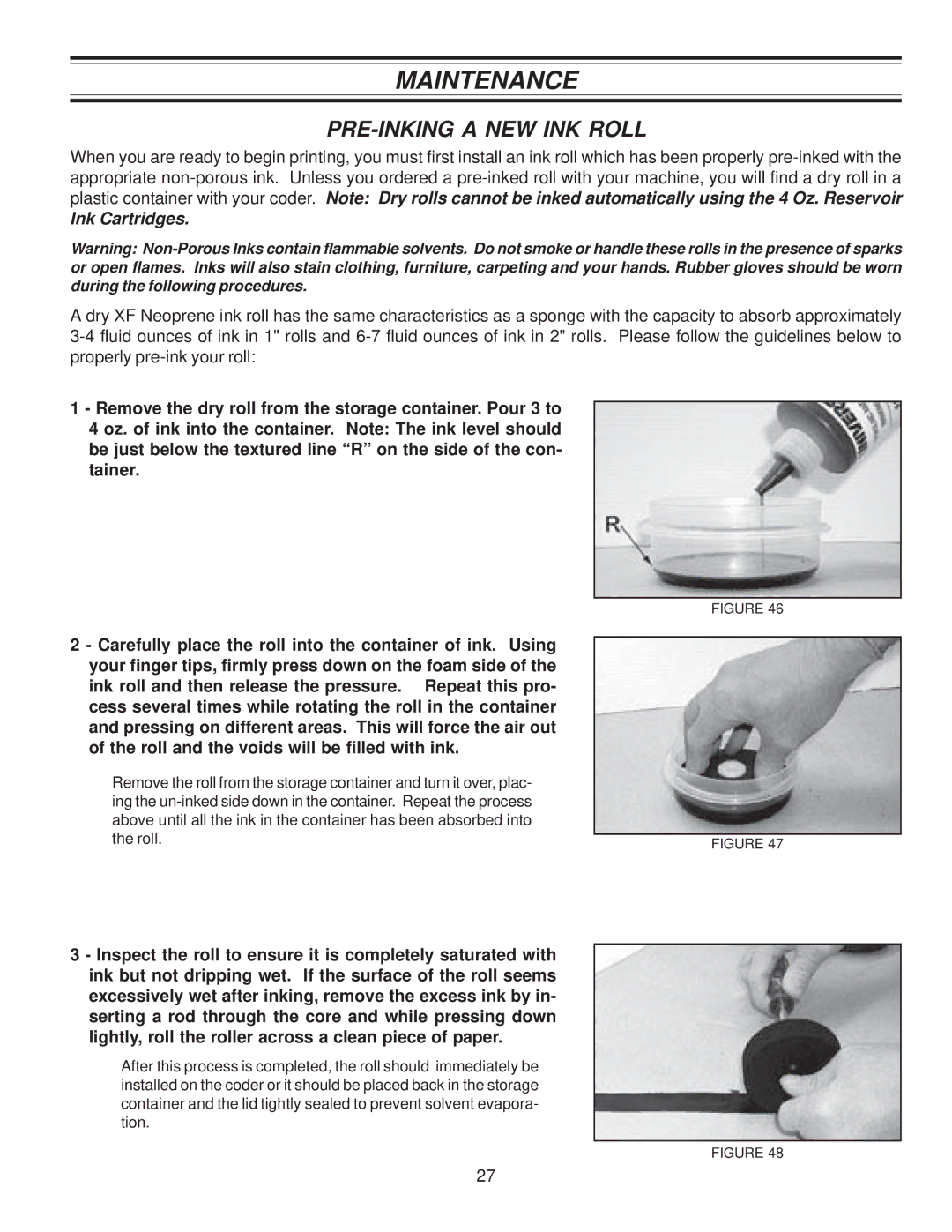

1 - Remove the dry roll from the storage container. Pour 3 to 4 oz. of ink into the container. Note: The ink level should be just below the textured line “R” on the side of the con- tainer.

FIGURE 46

2 - Carefully place the roll into the container of ink. Using your finger tips, firmly press down on the foam side of the ink roll and then release the pressure. Repeat this pro- cess several times while rotating the roll in the container and pressing on different areas. This will force the air out of the roll and the voids will be filled with ink.

Remove the roll from the storage container and turn it over, plac- ing the

3 - Inspect the roll to ensure it is completely saturated with ink but not dripping wet. If the surface of the roll seems excessively wet after inking, remove the excess ink by in- serting a rod through the core and while pressing down lightly, roll the roller across a clean piece of paper.

After this process is completed, the roll should immediately be installed on the coder or it should be placed back in the storage container and the lid tightly sealed to prevent solvent evapora- tion.

FIGURE 47

FIGURE 48

27