Direct Vent Models DVRT36 DVRT39 DVRT43

Homeowners Installation

Vermont Castings, Majestic Products

INSTALLER/CONSUMER SAFETY INFORMATION

Vermont Castings, Majestic Products DVRT36/39/43

Table of Contents

Installation & Operating Instructions

Venting Installation Instructions

Locating the Fireplace

Installation & Operating Instructions

Vermont Castings, Majestic Products DVRT36/39/43

10002428

Framing Dimensions

Fireplace Dimensions Installed as Top Vent

Vermont Castings, Majestic Products DVRT36/39/43

DVRT36

Vermont Castings, Majestic Products DVRT36/39/43

Fireplace Dimensions Installed as Rear Vent

10002428

Mantels

Clearance to Combustibles

Hearth

Vermont Castings, Majestic Products DVRT36/39/43

Framing & Finishing

Gas Specifications

Final Finishing

Gas Inlet and Manifold Pressures

Remote ON/ OFF Switch Installation

Gas Line Installation

Alternate Switch Location

Vermont Castings, Majestic Products DVRT36/39/43

Electronic Gas Control Valve

EB-1Electrical Box

Vermont Castings, Majestic Products DVRT36/39/43

10002428

Optional Top Vent Application

Installing the DVRT36RMH in a Mobile Home

Vermont Castings, Majestic Products DVRT36/39/43

10002428

Vermont Castings, Majestic Products DVRT36/39/43

General Venting

10002428

US Installations2

Canadian Installations1

Vermont Castings, Majestic Products DVRT36/39/43

10002428

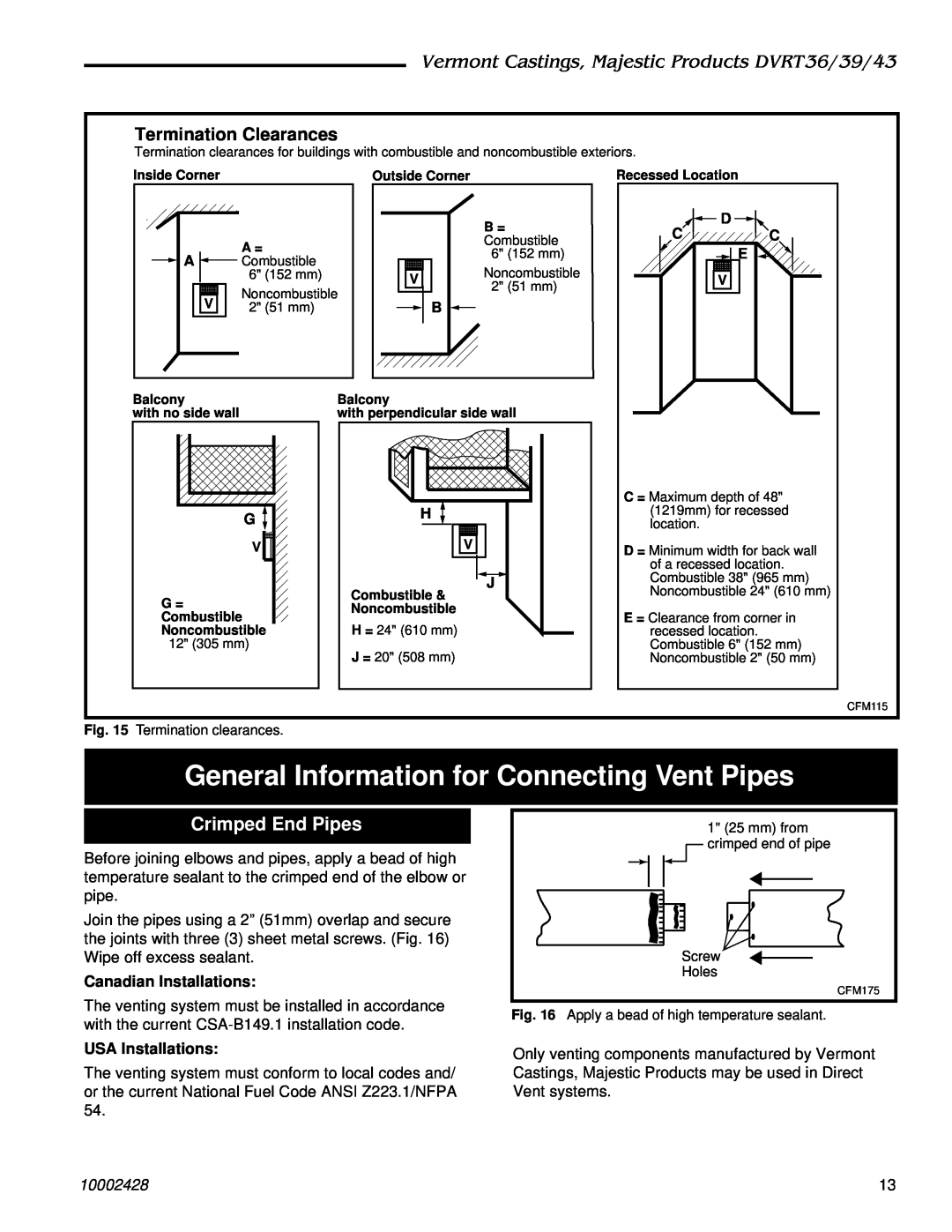

Crimped End Pipes

General Information for Connecting Vent Pipes

Vermont Castings, Majestic Products DVRT36/39/43

10002428

Twist-lockPipes

How to Use the Vent Graph

Rear Wall Vent Application

Vermont Castings, Majestic Products DVRT36/39/43

Vermont Castings, Majestic Products DVRT36/39/43

Rear Wall Vent Installation

Step

Step

Vermont Castings, Majestic Products DVRT36/39/43

Vertical Sidewall Application

10002428

Vermont Castings, Majestic Products DVRT36/39/43

Vertical Sidewall Installation

10002428

Vermont Castings, Majestic Products DVRT36/39/43

Below Grade Installation

10002428

Vermont Castings, Majestic Products DVRT36/39/43

Vertical Through-the-RoofApplication

Do not backfill around snorkel

10002428

Vermont Castings, Majestic Products DVRT36/39/43

Vertical Through-the-RoofInstallation

10002428

Vermont Castings, Majestic Products DVRT36/39/43

Gravity Ducting System

Clearance to Combustibles

Min 2’ 610 mm

Sheet Metal

Vermont Castings, Majestic Products DVRT36/39/43

Gravity

Screws

Vermont Castings, Majestic Products DVRT36/39/43

Twist Lock Venting Components

10002428

Vermont Castings, Majestic Products DVRT36/39/43

Crimped End Venting Components

10002428

Glass Cleaning

Window Frame Assembly Removal

Operating Instructions

Glass Information

Vermont Castings, Majestic Products DVRT36/39/43

Installation of Logs & Lava Rock

10002428

Flame Characteristics

Flame & Temperature Adjustment

Vermont Castings, Majestic Products DVRT36/39/43

10002428

Vermont Castings, Majestic Products DVRT36/39/43

Inspecting the Venting System

10002428

Lighting & Operating Instructions

FOR YOUR SAFETY, READ BEFORE LIGHTING

Lighting Instructions

To Turn Off Gas to Heater

before Lighting the Appliance

For Your Safety, Read the Following Warnings

Turning Off the Gas to the Appliance

Vermont Castings, Majestic Products DVRT36/39/43

Instructions for RF Comfort Control Valve

Shutoff Procedure

Operation of RF Comfort Control Valve

Transmitter Operation

Troubleshooting RF Comfort Control Valve

Disable Thermostat Function

Delay Time Mode

Auto Mode

Vermont Castings, Majestic Products DVRT36/39/43

Auto Path Chart

Auto Path

10002428

10002428

Vermont Castings, Majestic Products DVRT36/39/43

LOCAL to RE

LOCAL

Vermont Castings, Majestic Products DVRT36/39/43

Troubleshooting - Honeywell VS8421

10002428

SYMPTOM

Troubleshooting the Gas Control System

Vermont Castings, Majestic Products DVRT36/39/43

SIT NOVA 820 MILLIVOLT VALVE

Vermont Castings, Majestic Products DVRT36/39/43

Troubleshooting the Gas Control System

SIT 822 Valve with a Honeywell Electronic Igniter

START

Vermont Castings, Majestic Products DVRT36/39/43

Fuel Conversion Instructions

10002428

Cleaning the Standing Pilot Control System

Maintenance

Vermont Castings, Majestic Products DVRT36/39/43

10002428

Vermont Castings, Majestic Products DVRT36/39/43

DVRT36/39/43

10002428

DVRT43

Description

Vermont Castings, Majestic Products DVRT36/39/43

DVRT36

DVRT39

Vermont Castings, Majestic Products DVRT36/39/43

DVRT36/39/43 continued

10002428

Hard Direct Wire Hookup

Optional Accessories

Fan Kits

Vermont Castings, Majestic Products DVRT36/39/43

Ceramic Refractory Panels

Remote Controls

Decorative Bay Window

Vermont Castings, Majestic Products DVRT36/39/43

Vermont Castings, Majestic Products DVRT36/39/43

Decorative Frame Trim

10002428

Fig. 62 Bay window

Conversion Instructions

For Use in Mobile Homes Model DVRT36RMH

Vermont Castings, Majestic Products DVRT36/39/43

10002428

9b.Units with Honeywell valve

Vermont Castings, Majestic Products DVRT36/39/43

10002428

PRODUCT COVERED BY THIS WARRANTY

LIMITED LIFETIME WARRANTY

IF WARRANTY SERVICE IS NEEDED…

Vermont Castings, Majestic Products DVRT36/39/43

10002428

Vermont Castings, Majestic Products DVRT36/39/43

Vermont Castings, Majestic Products

Efficiency Ratings

Model

EnerGuide Ratings

![]()

![]() D

D ![]()

![]()

![]() E

E![]() crimped end of pipe

crimped end of pipe