INSTALLATION

SYSTEM DATA - E65-1

(WITH 38,000 BTU)

For 0 to 2000* feet altitude |

| |

Burner Inlet Orifice Sizes: |

| |

| Natural Gas | Propane |

Burner | #32 | #50 |

*Above 2000 ft. see National Fuel Code Orifice Chart.

Max. Input Rating |

|

- Natural Gas | 38,000 Btu/h |

- Propane | 38,000 Btu/h |

Min. Input Rating |

|

- Natural Gas | 19,000 Btu/h |

- Propane | 19,000 Btu/h |

|

|

Output Capacity with blower Off*

Natural Gas | 29,070 Btu/h |

Propane | 29,650 Btu/h |

Output Capacity with blower On *

Natural Gas | 29,564 Btu/h |

Propane | 30,172 Btu/h |

*See page 8 for manufactured home chart.

Supply Pressure |

|

|

Natural Gas | min. | 5.0" w.c. |

Propane | min. | 12.0" w.c. |

|

|

|

Manifold Pressure |

|

|

Natural Gas | 3.8" | +/- 0.2" w.c. |

Propane | 11" | +/- 0.2" w.c. |

SYSTEM DATA

HIGH ELEVATION: E65-NG1

For 2,000 - 4,500 feet altitude

Burner Inlet Orifice Sizes:

Natural Gas

Burner | #33 |

|

|

Max. Input Rating |

|

- Natural Gas | 36,100 Btu/h |

Min. Input Rating |

|

- Natural Gas | 18,000 Btu/h |

Output Capacity with blower Off

Natural Gas | 27,616 Btu/h |

Max. Output Capacity with blower On

Natural Gas | 28,086 Btu/h |

HIGH ELEVATION

This unit (with 38,000 Btu) is approved in Can- ada for altitude 2000 ft. to 4500 ft. (CAN/CGA-

SYSTEM DATA -

E65-1 CONVERTED TO

27,000 (NATURAL GAS) OR 29,000 (PROPANE)

For 0 to 4500 feet altitude |

| |

Burner Inlet Orifice Sizes: |

| |

Natural Gas | Propane | |

Burner | #40 | #52 |

|

|

|

Max. Input Rating |

|

|

- Natural Gas | 27,000 Btu/h | |

- Propane | 29,000 Btu/h | |

Min. Input Rating |

|

|

- Natural Gas | 13,500 Btu/h | |

- Propane | 14,500 Btu/h | |

| ||

Output Capacity with blower Off* | ||

Natural Gas | 19,845 Btu/h | |

Propane | 22,040 Btu/h | |

Output Capacity with blower On * | ||

Natural Gas | 20,385 Btu/h | |

Propane | 22,765 Btu/h | |

*See page 8 for manufactured home chart.

Supply Pressure |

|

|

Natural Gas | min. | 5.0" w.c. |

Propane | min. | 12.0" w.c. |

|

|

|

Manifold Pressure |

|

|

Natural Gas | 3.8" | +/- 0.2" w.c. |

Propane | 11" | +/- 0.2" w.c. |

GAS CONNECTION

The gas connection is a 3/8" NPT 90o elbow. The gas line can be rigid pipe or to make installation easier, use a listed flexible connec- tor and/or copper tubing if allowed by local codes. Since some municipalities have addi- tional local codes it is always best to consult with your local authorities and the CAN/CGA B149 installation codes.

For USA installations follow local codes and/ or the current National Fuel Gas Code, ANSI Z223.1.

When using copper or flex connectors use only approved fittings. Always provide a union so that gas lines can be easily disconnected for burner and/or valve servicing. Flare nuts for copper lines and flex connectors are usu- ally considered to meet this requirement.

IMPORTANT: ALWAYS CHECK FOR GAS LEAKS WITH A SOAP AND WATER SOLUTION OR GAS LEAK DETECTOR. DO NOT USE OPEN FLAME FOR LEAK TESTING.

Note: Prior to any pressure testing of the gas supply piping system that exceeds test pressures of 1/2 psig, this appliance must be dis- connected from the piping sys- tem. If test pressures equal to or less than 1/2 psig are used then this appliance must be isolated from the piping system by closing

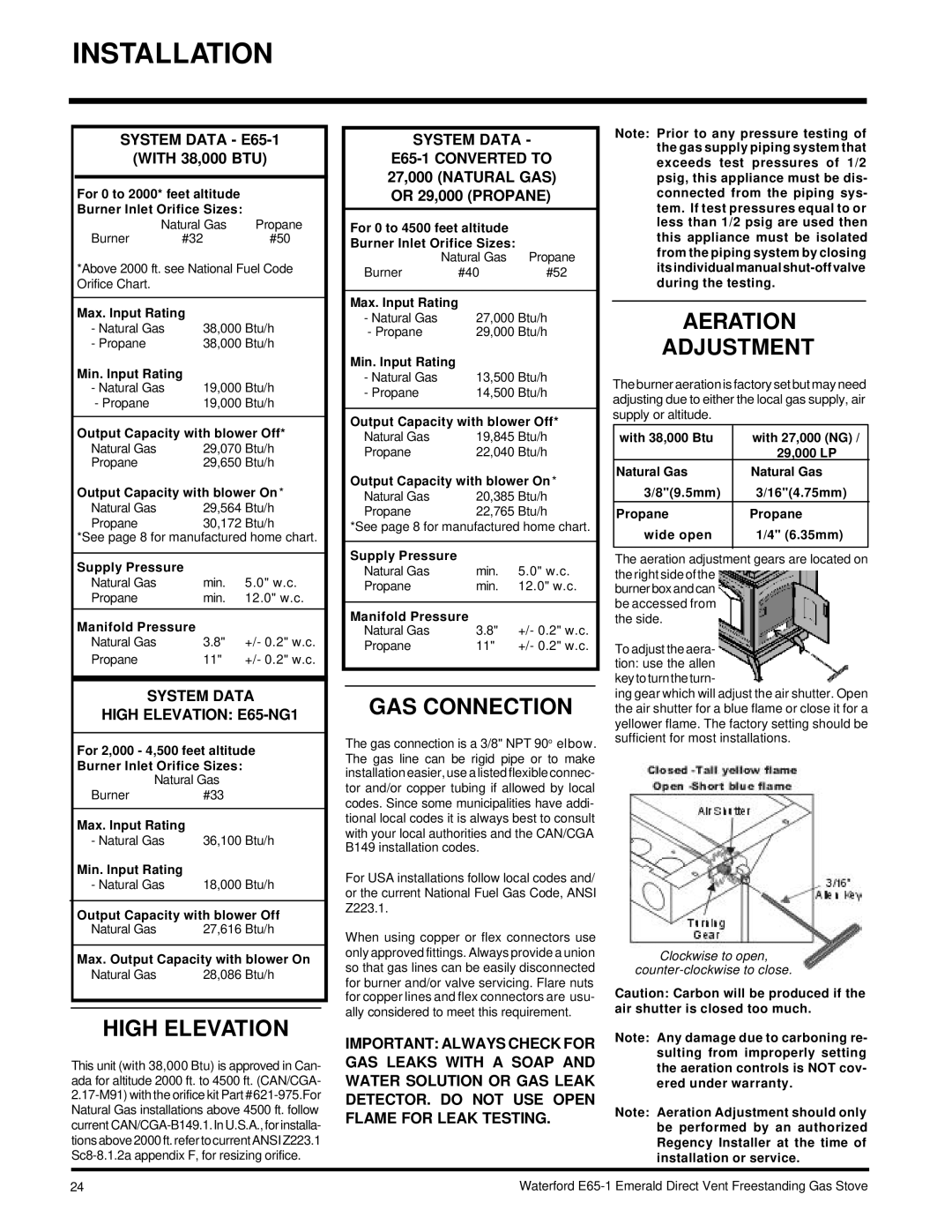

AERATION

ADJUSTMENT

The burner aeration is factory set but may need adjusting due to either the local gas supply, air supply or altitude.

with 38,000 Btu | with 27,000 (NG) / |

| 29,000 LP |

Natural Gas | Natural Gas |

3/8"(9.5mm) | 3/16"(4.75mm) |

Propane | Propane |

wide open | 1/4" (6.35mm) |

|

|

The aeration adjustment gears are located on the right side of the

burner box and can be accessed from the side.

To adjust the aera- tion: use the allen key to turn the turn-

ing gear which will adjust the air shutter. Open the air shutter for a blue flame or close it for a yellower flame. The factory setting should be sufficient for most installations.

Clockwise to open,

Caution: Carbon will be produced if the air shutter is closed too much.

Note: Any damage due to carboning re- sulting from improperly setting the aeration controls is NOT cov- ered under warranty.

Note: Aeration Adjustment should only be performed by an authorized Regency Installer at the time of installation or service.

24

Waterford