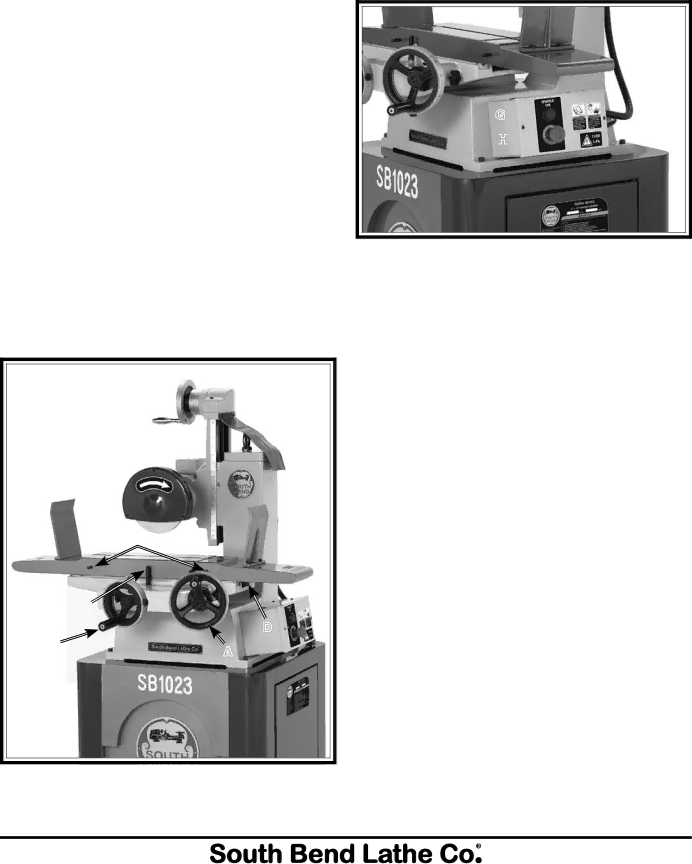

Model SB1023 | O P E R A T I O N | For Machines Mfg. Since 8/09 |

Controls

Refer to Figures

A.Longitudinal Travel Handwheel: Moves the table back and forth along the longitudinal axis

B.Center Table Stop: Provides a barrier for the table stops to limit table movement.

C.Table Stop: Adjusts along the length of the table to limit longitudinal travel.

D.Cross Axis Lock Knob: Locks the cross table movement

E.Elevation Handwheel: Controls vertical movement of the grinding wheel assembly.

F.Cross Travel Handwheel: Moves the table forward and backward along the cross axis

G.Spindle On Button: Supplies power to the grinding wheel motor.

H.Emergency Stop (Off) Button: Cuts power to the grinding wheel motor.

G ![]()

H![]()

![]()

![]()

Figure 11. Control panel.

E![]()

![]()

![]()

![]()

C

| B | |

F | D | |

A | ||

|