2. Continue Adding Vent Components

•Continue adding vent components, locking each succeed- ing component into place.

•Ensure that each succeeding vent component is secure- ly fitted and locked into the preceding component.

•90° elbows may be installed and rotated to any point around the preceding component’s vertical axis. If an el- bow does not end up in a locked position with the pre- ceding component, attach with a minimum of two (2) sheet metal screws.

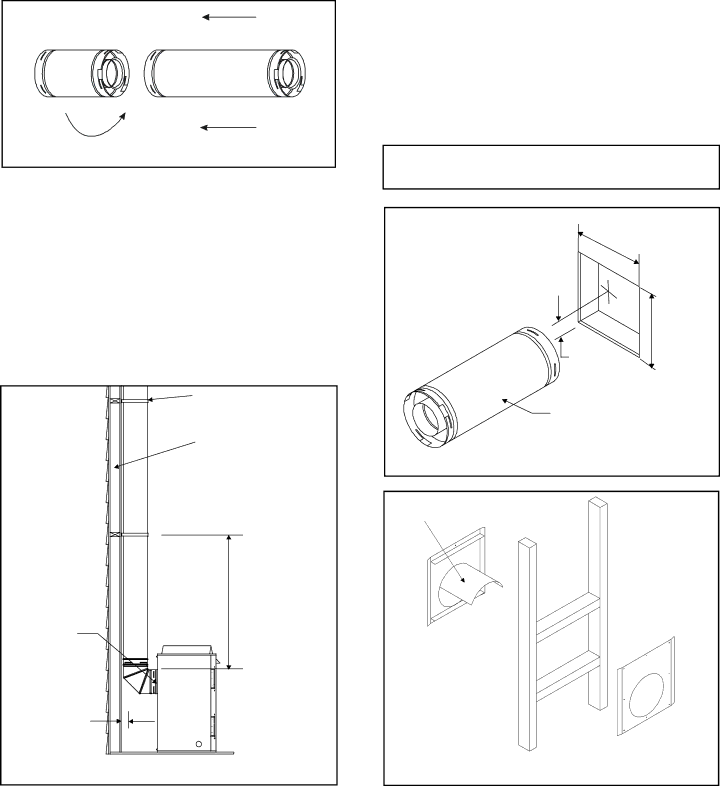

Figure 23. Adding Venting Components

3. Install Support Brackets

For Horizontal Runs - The vent system must be supported every five (5) feet of horizontal run by a horizontal pipe support.

To install support brackets for horizontal runs:

•Place the pipe supports around the vent pipe.

•Nail the pipe supports to the framing members.

For Vertical Runs - The vent system must be supported every eight (8) feet (2.4m) above the fireplace flue outlet by wall brackets. To install support brackets for vertical runs:

•Attach wall brackets to the vent pipe and secure the wall bracket to the framing members with nails or screws.

WALL BRACKET |

WALL STUD |

4. Install Firestops

For Horizontal Runs - Firestops are REQUIRED on both sides of a combustible wall through which the vent passes.

NOTE: Model

To install firestops for horizontal runs that pass through either interior or exterior walls:

Cut a

mm)hole for

•Position the firestops on both sides of the hole previ- ously cut and secure the firestops with nails or screws.

•The heat shields of the firestops MUST BE placed to- wards the top of the hole.

•Continue the vent run through the firestops.

NOTE: There must be NO INSULATION or other combus- tibles inside the framed firestop opening.

12" or 10"

(305mm or 254mm)

1" (25.4 mm)

12" or 10" (305mm or 254mm)

VENT PIPE

Figure 25. Hole and Vent Pipe

8 FT. (2.4m) |

FLUE |

OUTLET |

1 INCH MIN. |

(25.4mm) |

HEAT SHIELD

INTERIOR

FIRESTOP

TRIM HEAT SHIELD IF TOO LONG, ADD TO SHIELD IF TOO SHORT

EXTERIOR

FIRESTOP

Figure 24. Installing Support Brackets

Figure 26. Heat Shield, Interior & Exterior Firestops

27