AIR |

|

| Bottom | ALTERNATE FLUE AND |

DISCHARGE |

| |||

| COMBUSTION AIR PIPE | |||

| ALTERNATE FLUE PIPE |

| Return | |

|

| LOCATIONS | ||

| LOCATION |

| Duct | |

|

|

| ||

|

|

| Connection |

|

Side | Side |

|

|

|

Return | Return |

|

|

|

Duct | Duct |

|

|

|

Connection | Connection |

|

|

|

| Bottom |

|

|

|

| Return |

|

|

|

| Duct |

|

| AIR |

| Connection |

|

| |

|

| DISCHARGE | ||

|

|

| ||

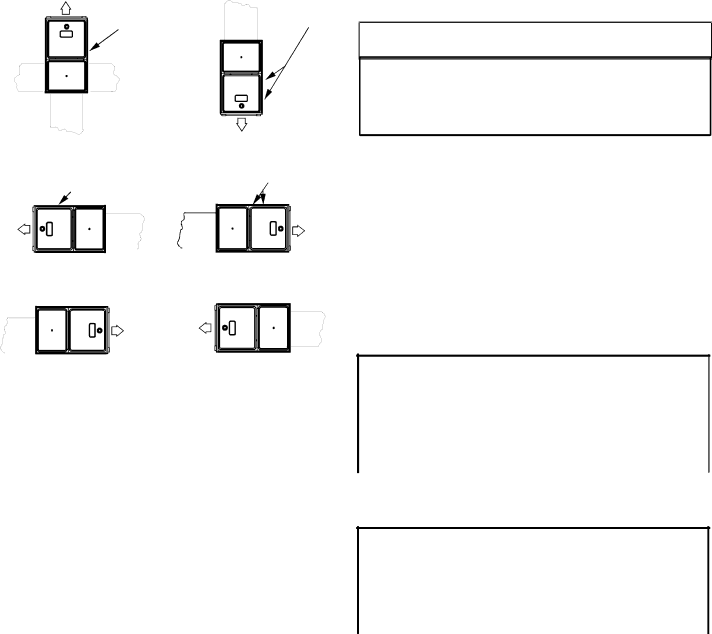

| UPFLOW | COUNTERFLOW | ||

| UPRIGHT |

| UPRIGHT | |

|

|

|

| ALTERNATE FLUE AND |

| ALTERNATE FLUE |

|

| COMBUSTION AIR PIPE |

|

|

| LOCATIONS | |

| PIPE LOCATION |

|

|

|

| Bottom | Bottom |

|

|

| Return | Return |

| AIR |

AIR | Duct |

| ||

Duct |

| |||

| DISCHARGE | |||

DISCHARGE | Connection | Connection |

| |

|

| |||

UPFLOW HORIZONTAL | COUNTERFLOW HORIZONTAL | |||

LEFT AIR DISCHARGE | RIGHT AIR DISCHARGE | |||

|

|

|

| Bottom |

Bottom |

|

|

| Return |

Return | AIR | AIR |

| Duct |

Duct |

| Connection | ||

Connection | DISCHARGE | DISCHARGE |

|

|

UPFLOW HORIZONTAL | COUNTERFLOW HORIZONTAL | |

LEFT AIR DISCHARGE | ||

RIGHT AIR DISCHARGE | ||

|

Recommended Installation Positions

NOTE: Alternate “vertical” piping connections can not be used when an upflow furnace is installed with supply air discharging to the right, or when a counterflow furnace is installed with supply air discharging to the left. In either case, use the standard flue and combustion air piping connections.

VIII. PROPANE GAS /HIGH ALTITUDE INSTALLATIONS

![]() WARNING

WARNING

POSSIBLE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH MAY OCCUR IF THE CORRECT CONVERSION KITS ARE NOT INSTALLED. THE APPROPRIATE KITS MUST BE APPLIED TO ENSURE SAFE AND PROPER FURNACE OPERATION. ALL CONVERSIONS MUST BE PERFORMED BY A QUALIFIED INSTALLER OR SERVICE AGENCY.

This furnace is shipped from the factory configured for natural gas at standard altitude. Propane gas installations require an orifice change to compensate for the energy content difference between natural and propane gas.

For furnaces being converted to LP gas, it is strongly recommended that a LPLP03 kit also be installed. The use of this kit will prevent the furnace from firing when the LP gas supply pressure is too low to support proper combustion.

High altitude installations may require both a pressure switch and an orifice change. These changes are necessary to compensate for the natural reduction in the density of both the gas fuel and the combustion air at higher altitude.

For installations above 7000 feet, please refer to your distributor for required kit(s).

*MH95, ACSH96, GCH95, GCH9 GAS ORIFICE CHART

Altitude | Gas | Kit | Orifice | Manifold | Pressure | |

Pressure | Switch | |||||

|

|

|

| |||

| Natural | None | #43 | 3.5" w.c. |

| |

|

|

|

| None | ||

Propane | #55 | 10.0" w.c. | ||||

|

| |||||

|

|

|

|

|

|

ALTERNATE ELECTRICAL AND GAS LINE CONNECTIONS

This furnace has provisions allowing for electrical and gas line connections through either side panel. In horizontal applications the connections can be made either through the “top” or “bottom” of the furnace.

DRAIN PAN

A drain pan must be provided if the furnace is installed above a conditioned area. The drain pan must cover the entire area under the furnace (and air conditioning coil if applicable).

FREEZE PROTECTION

Refer to Horizontal Applications and Conditions - Drain Trap and Lines.

FURNACE SUSPENSION

If the furnace is installed in a crawl space it must be suspended from the floor joist or supported by a concrete pad. Never install the fur- nace on the ground or allow it to be exposed to water. Refer to Loca- tion Requirements and Considerations - Furnace Suspension for fur- ther details.

2

AMEH96, GME95 GAS ORIFICE CHART

Altitude | Gas | Kit | Orifice | Manifold | Pressure | |

Pressure | Switch | |||||

|

|

|

| |||

| Natural | None | #45 | 3.5" w.c. |

| |

|

|

|

| None | ||

Propane | #55 | 10.0" w.c. | ||||

|

| |||||

|

|

|

|

|

|

2

Contact the distributor for a tabular listing of appropriate manufacturer’s kits for propane gas and/or high altitude installations. The indicated kits must be used to insure safe and proper furnace operation. All conversions must be performed by a qualified installer, or service agency.

13