V![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

X ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

v

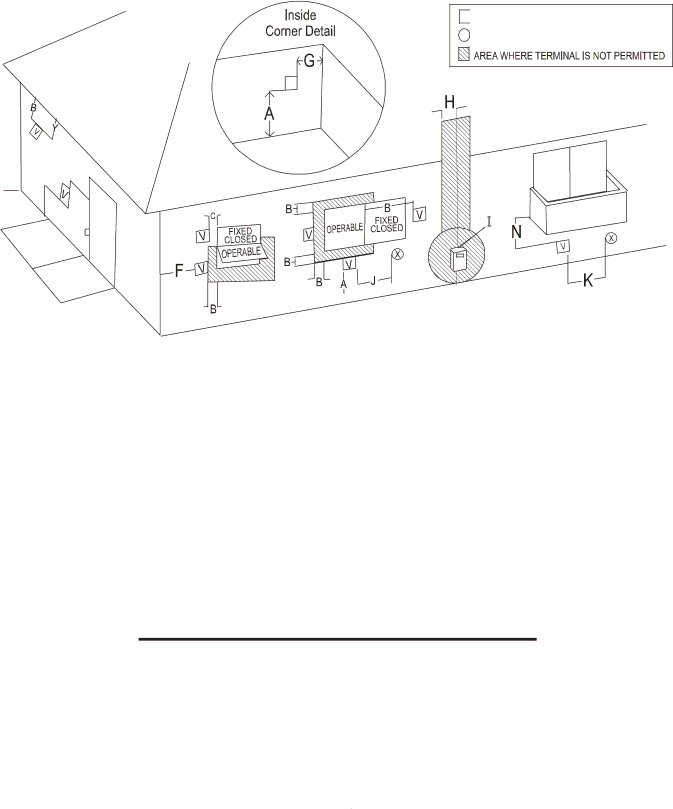

DIRECT VENT TERMINAL CLEARANCES

|

| Canadian Installations1 | U.S. Installations 2 |

A= | Clearance above grade, | 12 in. (30 cm) | 12 in. (30 cm) |

| veranda, porch, deck or |

|

|

| balcony. (See |

|

|

|

|

|

|

B= | Clearance to window or | 6 in. (15 cm) for appliances | 6 in. (15 cm) for appliances |

| door that may be opened. | 10,000 Btuh (3 kW), 12 in. (30 cm) for | 10,000 Btuh (3 kW), 9 in. (23 cm) for |

|

| appliances > 10,000 Btuh (3 kW) and | appliances > 10,000 Btuh (3 kW) and |

|

| 100,000 Btuh (30 kW), 36 in. (91 cm) | 50,000 Btuh (15 kW), 12 in. (30 cm) for |

|

| for appliances > 100,000 Btuh (30 | appliances > 500,000 Btuh (15 kW). |

|

| kW). |

|

|

|

|

|

C= | Clearance to permanently | * | * |

| closed window. |

|

|

|

|

|

|

D= | Vertical clearance to ventilated soffit | * | * |

| located above the terminal within a |

|

|

| horizontal distance of 2 feet (61 cm) |

|

|

| from the center line of the terminal. |

|

|

|

|

|

|

E= | Clearance to unventilated soffit. | * | * |

|

|

|

|

F= | Clearance to outside corner. | * | * |

|

|

|

|

G= | Clearance to inside corner. | * | * |

|

|

|

|

H= | Clearance to each side of center | 3 ft. (91 cm) within a height 15 ft. | * |

| line extended above meter/regulator | (4.5 m) above the meter/regulator |

|

| assembly. | assembly. |

|

|

|

|

|

|

| Canadian Installations 1 | U.S. Installations 2 |

I= | Clearance to service | 3 ft. (91 cm). | * |

| regulator vent outlet. |

|

|

|

|

|

|

J= | Clearance to nonmechanical air | 6 in. (15 cm) for appliances 10,000 | 6 in. (15 cm) for appliances 10,000 |

| supply inlet to building or the | Btuh (3 kW), 12 in. (30 cm) for | Btuh (3 kW), 9 in. (23 cm) for |

| combustion air inlet to any other | appliances > 10,000 Btuh (3kW) and | appliances > 10,000 Btuh (3kW) and |

| appliance. | 100,000 Btuh (30 kW), 36 in. (91 cm) | 50,000 Btuh (15 kW), 12 in. (30 cm) for |

|

| for appliances > 100,000 Btuh (30 kW). | appliances > 50,000 Btuh (15 kW). |

|

|

|

|

K= | Clearance to a mechanical | 6 ft. (1.83 m) | 3 ft. (91 cm) above if within |

| air supply inlet. |

| 10 ft. (3 m) horizontally. |

|

|

|

|

L= | Clearance above paved sidewalk or | 7 ft. (2.13m) † | * |

| paved driveway located on public |

|

|

| property. |

|

|

|

|

|

|

M= | Clearance under veranda, porch, | 12 in. (30 cm) ‡ | * |

| deck or balcony. |

|

|

1In accordance with the current CSA B149.1, Natural Gas and Propane Installation Code.

2In accordance with the current ANSI Z223.1/NFPA 54, National Fuel Gas Code.

†A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single fanily dwellings and serves both dwellings.

‡Permitted only if veranda, porch, deck or balcony is fully open on a minimum of two sides beneath the floor.

*For clearances not specified in ANSI Z223.1/NFPA 54 or CSA B149.1, the following statement shall be included:

“Clearance in accordance wtih local installation codes and the requirements of the gas supplier and the manufacturer’s installation instruction.”

OTHER THAN DIRECT VENT TERMINAL CLEARANCES

|

| Canadian Installations 1 | U.S. Installations 2 |

A= | Clearance above grade, | 12 in. (30 cm) | 12 in. (30 cm) |

| veranda, porch, deck or |

|

|

| balcony. (See |

|

|

|

|

|

|

B= | Clearance to window or | 6 in. (15 cm) for appliances | 4 ft. (1.2 m) below or to side of |

| door that may be opened. | 10,000 Btuh (3 kW), 12 in. (30 cm) for | opening; 1 ft. (300 m) above opening. |

|

| appliances > 10,000 Btuh (3 kW) and |

|

|

| 100,000 Btuh (30 kW), 36 in. (91 cm) |

|

|

| for appliances > 100,000 Btuh (30 |

|

|

| kW). |

|

|

|

|

|

C= | Clearance to permanently | * | * |

| closed window. |

|

|

|

|

|

|

D= | Vertical clearance to ventilated soffit | * | * |

| located above the terminal within a |

|

|

| horizontal distance of 2 feet (61 cm) |

|

|

| from the center line of the terminal. |

|

|

|

|

|

|

E= | Clearance to unventilated soffit. | * | * |

|

|

|

|

F= | Clearance to outside corner. | * | * |

|

|

|

|

G= | Clearance to inside corner. | * | * |

|

|

|

|

H= | Clearance to each side of center | 3 ft. (91 cm) within a height 15 ft. | * |

| line extended above meter/regulator | (4.5 m) above the meter/regulator |

|

| assembly. | assembly. |

|

|

|

|

|

|

| Canadian Installations1 | U.S. Installations2 |

I= | Clearance to sevice | 3 ft. (91 cm). | * |

| regulator vent outlet. |

|

|

|

|

|

|

J= | Clearance to nonmechanical air | 6 in. (15 cm) for appliances 10,000 | 4 ft. (1.2 m) below or to side of |

| supply inlet to building or the | Btuh (3 kW), 12 in. (30 cm) for | opening; 1 ft. (300 m) above opening. |

| combustion air inlet to any other | appliances > 10,000 Btuh (3kW) and |

|

| appliance. | 100,000 Btuh (30 kW), 36 in. (91 cm) |

|

|

| for appliances > 100,000 Btuh (30 kW). |

|

|

|

|

|

K= | Clearance to a mechanical | 6 ft. (1.83 m) | 3 ft. (91 cm) above if within |

| air supply inlet. |

| 10 ft. (3 m) horizontally. |

|

|

|

|

L= | Clearance above paved sidewalk or | 7 ft. (2.13m) † | 7 ft. (2.13m) |

| paved driveway located on public |

|

|

| property. |

|

|

|

|

|

|

M= | Clearance under veranda, porch, | 12 in. (30 cm) ‡ | * |

| deck or balcony. |

|

|

1In accordance with the current CSA B149.1, Natural Gas and Propane Installation Code.

2In accordance with the current ANSI Z223.1/NFPA 54, National Fuel Gas Code.

†A vent shall not terminate directly above a sidewalk or paveable driveway that is located between two single family dwellings and serves both dwelling.

‡Permitted only if veranda, porch, deck or balcony is fully open on a minimum of two sides beneath the floor.

*For clearances not specified in ANSI Z223.1/NFPA 54 or CSA B149.1, the following statement shall be included:

“Clearance in accordance wtih local installation codes and the requirements of the gas supplier and the manufacturer’s installation instruction.”

14