![]() Chimney or Gas Vent

Chimney or Gas Vent

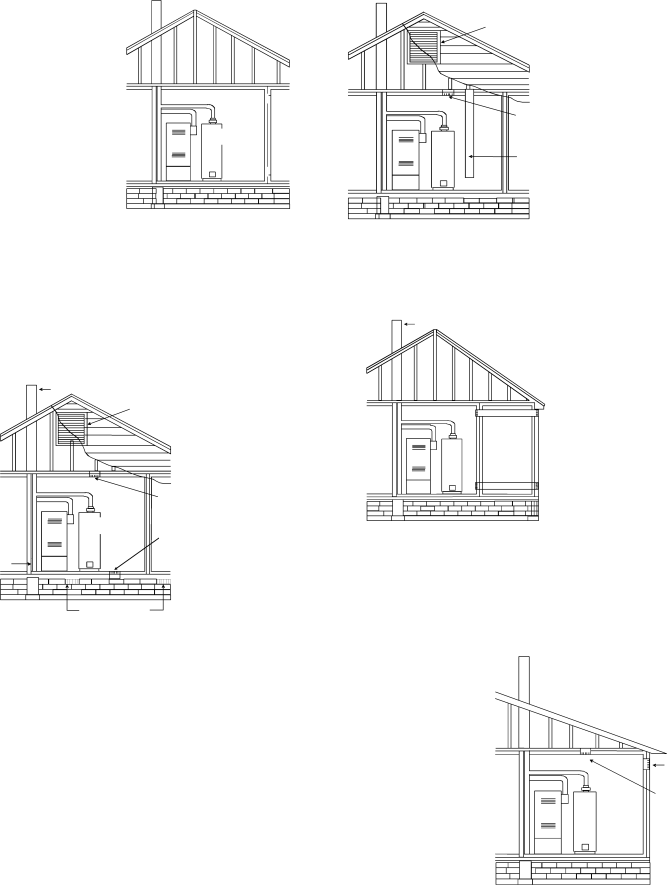

NOTE: Each opening must have a free area of not less than one square inch per 1000 BTU of the total input rating of all equip- ment in the enclosure, but not less than 100 square inches.

![]()

![]() Opening

Opening

Water

Furnace Heater

![]()

![]() Opening

Opening

![]() Chimney or Gas Vent

Chimney or Gas Vent

Ventilation louvers (each end of attic)

NOTE: The inlet and outlet air openings must each have a free area of not less than one square inch per 4000 BTU of the

total input rating of all equipment in the enclosure.

|

|

|

|

| Outlet Air | |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

| Water | |||

|

|

| Heater |

|

| |

Furnace | Inlet air duct | |||||

|

|

| ||||

|

|

|

|

| ||

|

|

|

|

| [ends 1 ft (300 mm) | |

|

|

|

|

| above floor] | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Equipment Located in Confined Spaces; All Air from Inside Building. |

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

Equipment Located in Confined Spaces; All Air from Outdoors | ||||||||||||||||||||||

See | ||||||||||||||||||||||

(b) All Air from Outdoors: The confined space shall be provided with |

|

|

|

|

|

|

|

| Through Ventilated Attic. See | |||||||||||||

|

|

| 3. When communicating with the outdoors through horizontal ducts, | |||||||||||||||||||

two permanent openings, one commencing within 12 inches of the |

|

|

| |||||||||||||||||||

top and one commencing within 12 inches of the bottom of the |

|

|

|

|

| each opening shall have a minimum free area of 1 square inch per | ||||||||||||||||

enclosure. The openings shall communicate directly, or by ducts, |

|

|

|

|

| 2,000 BTU per hour of total input rating of all equipment in the | ||||||||||||||||

with the outdoors or spaces (crawl or attic) that freely communicate |

|

|

|

|

| enclosure. | ||||||||||||||||

with the outdoors. |

|

|

|

|

|

|

| Chimney or Gas Vent | ||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

1.When directly communicating with the outdoors, each opening shall have a minimum free area of 1 square inch per 4,000 BTU

per hour of total input rating of all equipment in the enclosure. |

|

|

|

|

|

|

| NOTE: The air duct openings | |||

|

|

|

|

|

|

|

|

|

|

| must have a free area of not |

| Chimney or Gas Vent |

|

|

|

|

|

|

| less than one square inch per | ||

|

|

| Ventilation louvers |

|

|

|

|

|

|

| 2000 BTU of the total input |

|

|

|

|

|

|

|

|

|

| rating of all equipment in the | |

|

|

| (each end of attic) |

|

|

|

|

|

| Outlet air duct | enclosure*. |

|

|

| NOTE: The inlet and outlet air |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |

|

|

| openings must each have a free |

|

|

|

|

|

|

|

|

|

|

| area of not less than one square |

|

|

|

| Water |

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

| |||||

|

|

| inch per 4000 BTU of the |

|

|

| Heater |

|

|

| |

|

|

| Furnace |

| |||||||

|

|

|

|

|

|

|

|

| |||

|

|

| total input rating of all equipment |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |||

|

|

| in the enclosure. |

|

|

|

|

|

| Inlet air duct |

|

|

|

|

|

|

|

|

|

|

|

|

|

Outlet Air

Water |

|

|

|

|

| Heater |

|

|

| *If the appliance room is located against an outside wall and the air openings communicate directly with the |

|

|

| Furnace | Inlet Air | |||||

|

|

|

|

|

|

| outdoors, each opening shall have a free area of not less than one square inch per 4,000 BTU per hour of | ||

|

|

|

|

|

|

|

| ||

Alternate |

|

|

|

|

| the total input rating of all appliances in the enclosure. | |||

|

|

|

|

| Equipment Located in Confined Spaces; All Air from Outdoors. | ||||

air inlet |

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

| See |

|

|

|

|

|

|

|

|

| |

Ventilation louvers for unheated crawl space

Equipment Located in Confined Spaces; All Air from Outdoors— Inlet Air from Ventilated Crawl Space and Outlet Air to Ventilated Attic. See

2.When communicating with the outdoors through vertical ducts, each opening shall have a minimum free area of 1 square inch per 4,000 BTU per hour of total input rating of all equipment in the enclosure.

4.When ducts are used, they shall be of the same

NOTE: The single opening must have

a free area of not less than one![]() Chimney or Gas Vent square inch per 3000 BTU of

Chimney or Gas Vent square inch per 3000 BTU of

the total input rating of all equip-

ment in the enclosure, but not less than the sum of the areas of all vent connectors in the confined space.

|

|

|

|

|

|

| Opening |

|

|

|

|

|

|

| Alternate |

|

|

|

|

|

| ||

|

|

|

| Water |

| ||

|

|

|

|

|

| Opening | |

|

|

|

| Heater |

| ||

|

|

|

|

| |||

|

|

|

|

| Location | ||

Furnace |

|

|

|

|

| ||

|

|

|

|

| |||

Equipment Located in Confined Spaces; All Air from Outdoors -

Single Air Opening. See

11