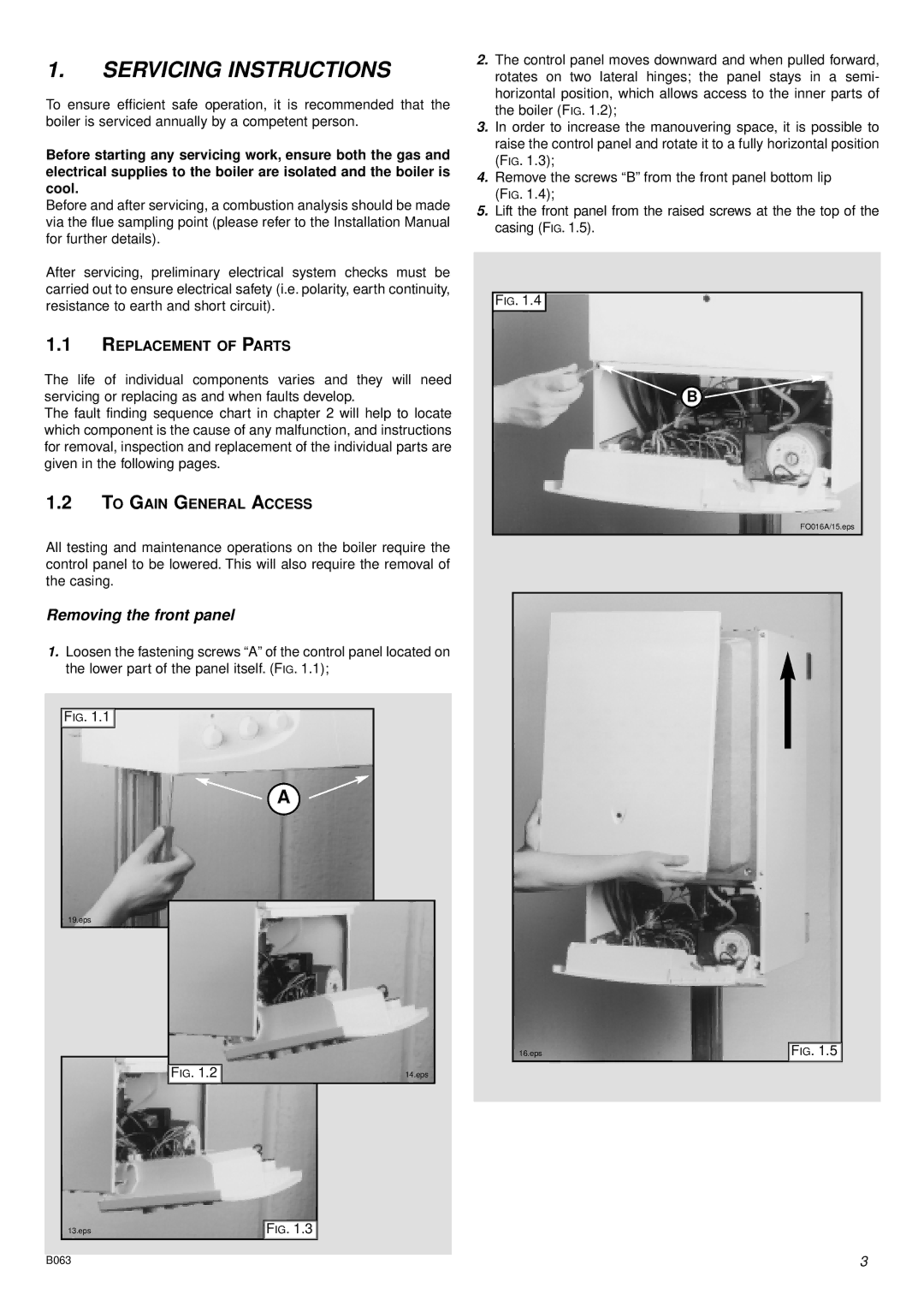

PIPE WORK:

Copper tubing to BS EN 1057:1996 is recommended for water pipes. Jointing should be either with capillary soldered or compression fittings. Where possible pipes should have a gradient to ensure air is carried naturally to air release points and water flows naturally to drain taps.

The appliance has a

Except where providing useful heat, pipes should be insulated to prevent heat loss and avoid freezing.

Particular attention should be paid to pipes passing through ventilated spaces in roofs and under floors.

The appliance includes an automatic

SYSTEM DESIGN:

This boiler is suitable only for sealed systems. Drain Cocks:

These must be located in accessible positions to permit the draining of the whole system. The taps must be at least 15mm nominal size and manufactured in accordance with BS 2870:1980.

SAFETY VALVE DISCHARGE:

The discharge should terminate facing downward on the exterior of the building in a position where discharging (possibly boiling water & steam) will not create danger or nuisance, but in an easily visible position, and not cause damage to electrical components and wiring.

The discharge must not be over an entrance or a window or any other type of public access.

AIR RELEASE POINTS:

These must be fitted at all high points where air naturally collects and must be sited to facilitate complete filling of the system.

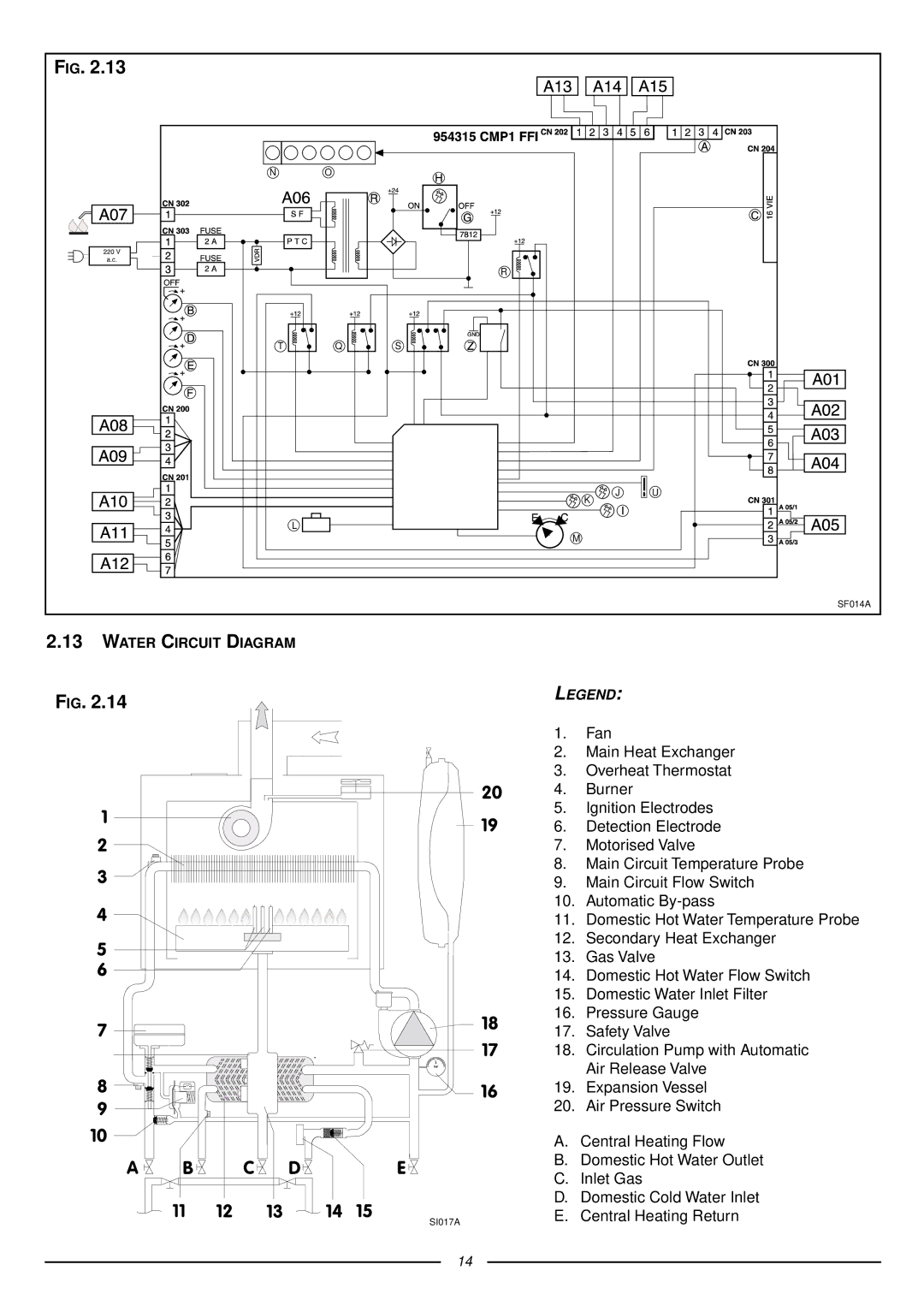

The appliance has an integral sealed expansion vessel to accommodate the increase of water value when the system is heated.

It can accept up to 6 l (1.3 gal) of expansion water. If the heating circuit has an unusually high water content, calculate the total expansion and add an additional sealed expansion vessel with adequate capacity.

MAINS WATER FEED - CENTRAL HEATING:

There must be no direct connection to the mains water supply even through a

FILLING:

A temporary method for initially filling the system and replacing lost water during servicing in accordance with Water Supply Byelaw 14 must be provided.

DOMESTIC WATER

The domestic water must be in accordance with the relevant recommendation of BS 5546:1990. Copper tubing to BS EN 1057:1996 is recommended for water carrying pipe work and must be used for pipe work carrying drinking water.

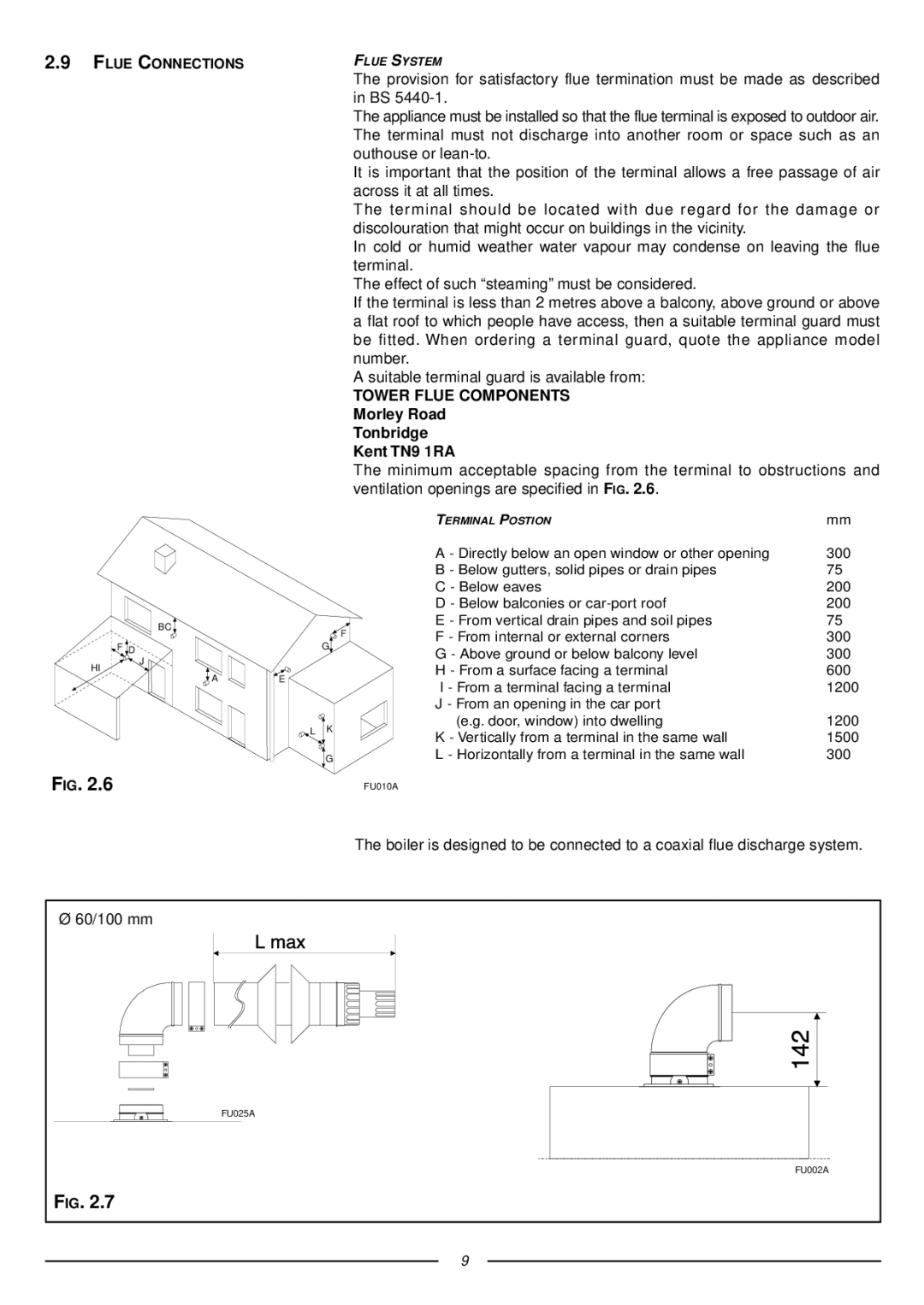

RESIDUAL HEAD OF THE BOILER

VR003A

8