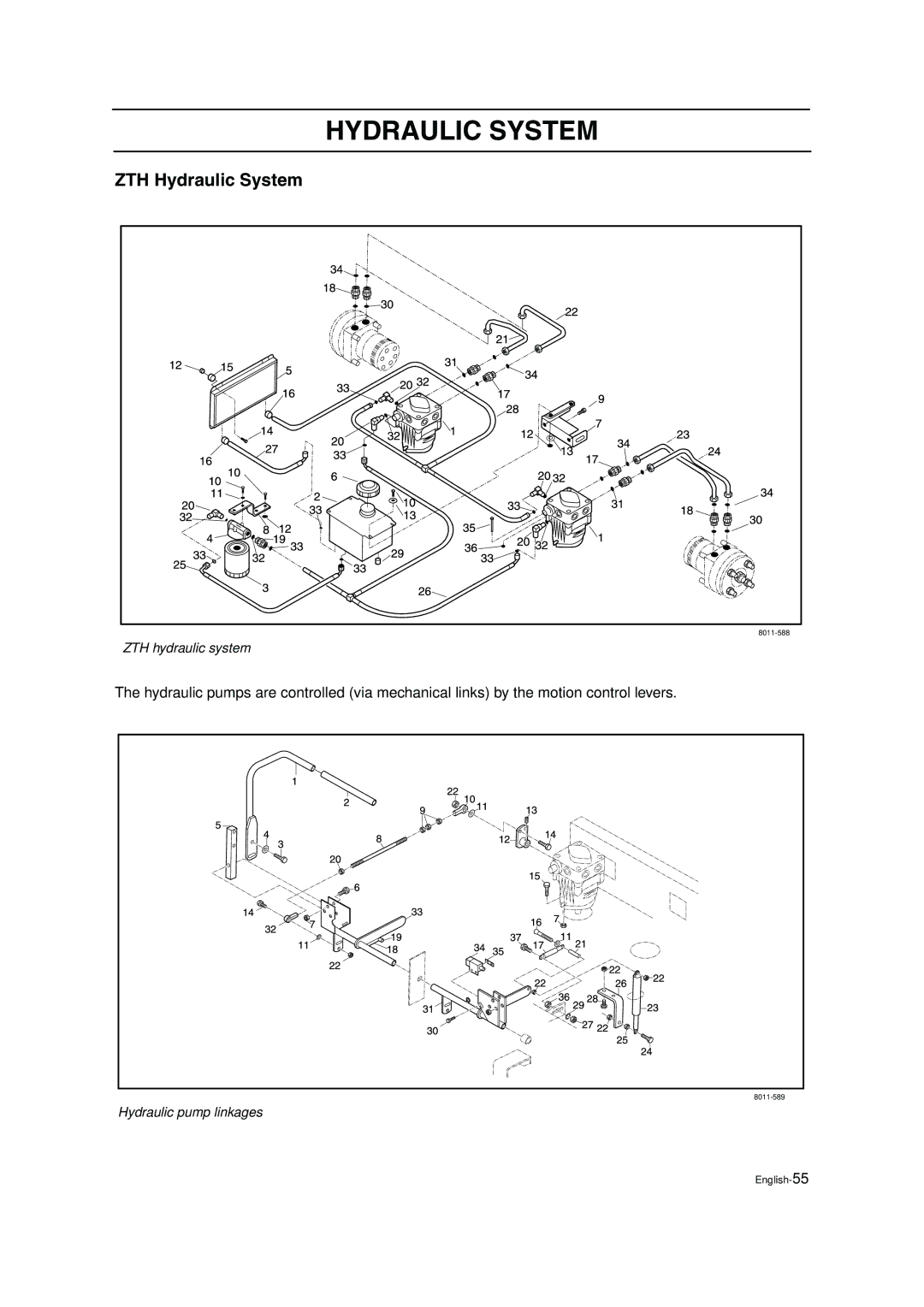

HYDRAULIC SYSTEM

Hydraulic Tank

Draining

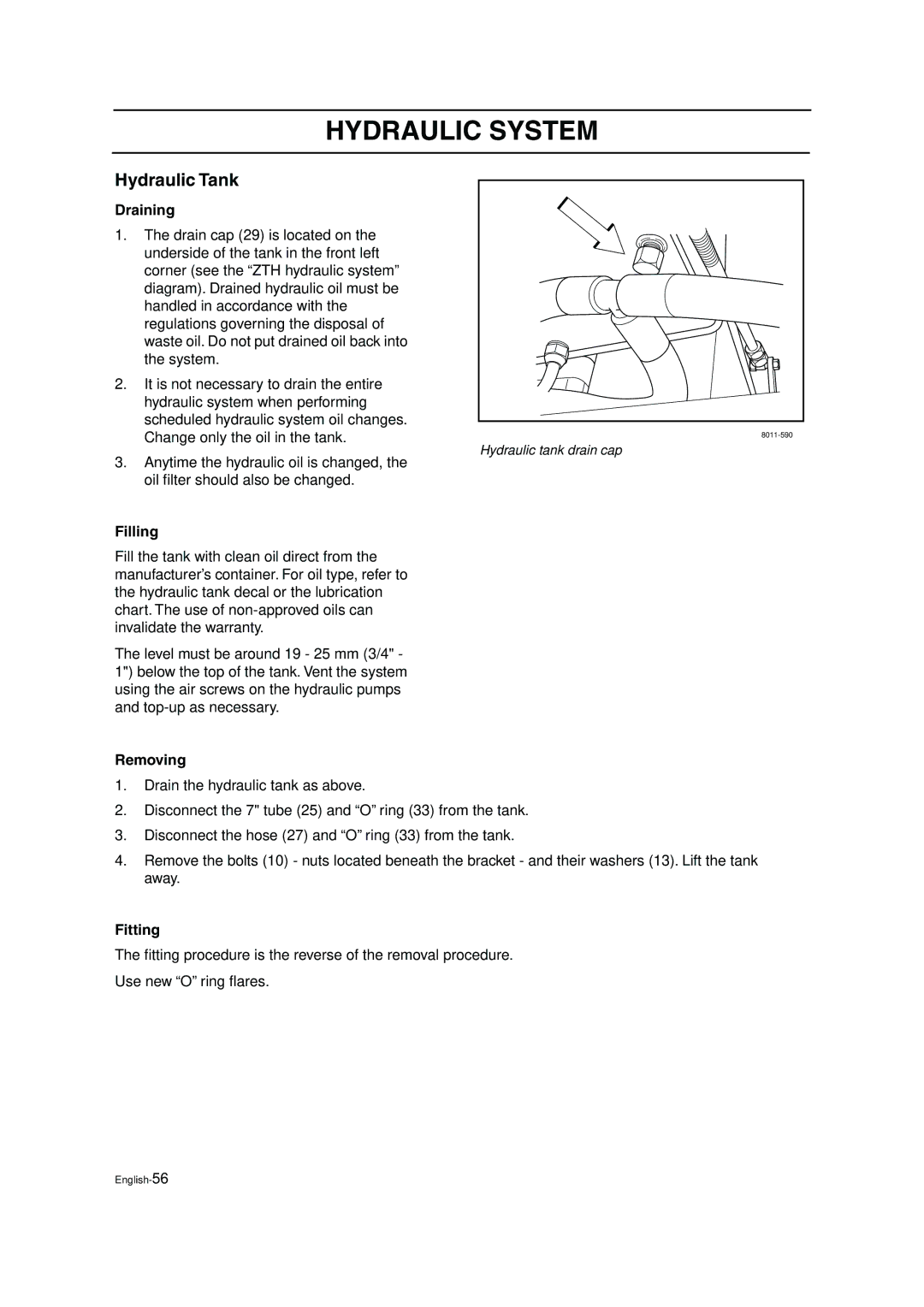

1.The drain cap (29) is located on the

underside of the tank in the front left corner (see the “ZTH hydraulic system” diagram). Drained hydraulic oil must be handled in accordance with the regulations governing the disposal of waste oil. Do not put drained oil back into the system.

2. It is not necessary to drain the entire |

|

hydraulic system when performing |

|

scheduled hydraulic system oil changes. |

|

Change only the oil in the tank. | |

| Hydraulic tank drain cap |

3.Anytime the hydraulic oil is changed, the oil filter should also be changed.

Filling

Fill the tank with clean oil direct from the manufacturer’s container. For oil type, refer to the hydraulic tank decal or the lubrication chart. The use of

The level must be around 19 - 25 mm (3/4" - 1") below the top of the tank. Vent the system using the air screws on the hydraulic pumps and

Removing

1.Drain the hydraulic tank as above.

2.Disconnect the 7" tube (25) and “O” ring (33) from the tank.

3.Disconnect the hose (27) and “O” ring (33) from the tank.

4.Remove the bolts (10) - nuts located beneath the bracket - and their washers (13). Lift the tank away.

Fitting

The fitting procedure is the reverse of the removal procedure.

Use new “O” ring flares.