Compact Station

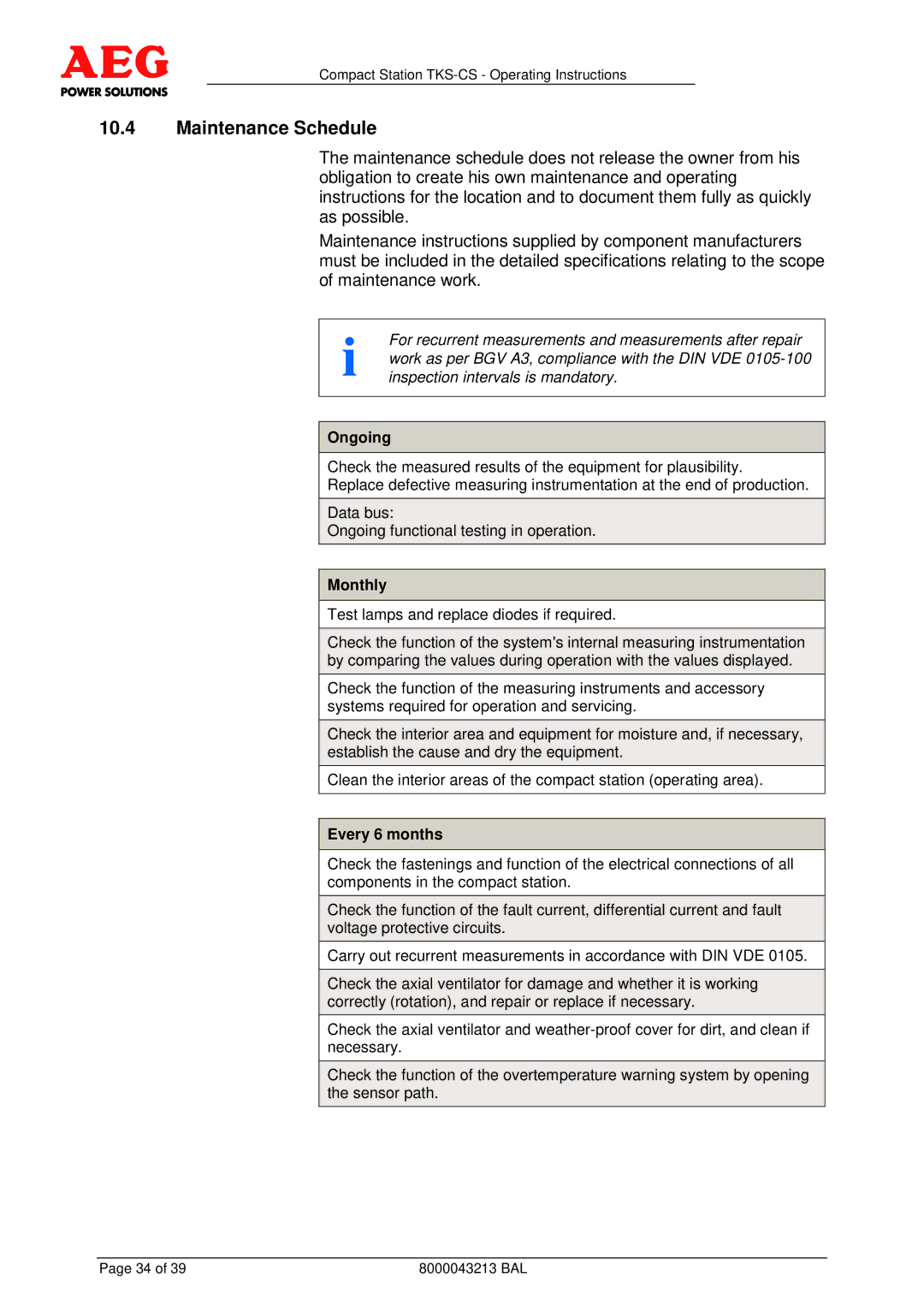

10.4Maintenance Schedule

The maintenance schedule does not release the owner from his obligation to create his own maintenance and operating instructions for the location and to document them fully as quickly as possible.

Maintenance instructions supplied by component manufacturers must be included in the detailed specifications relating to the scope of maintenance work.

i | For recurrent measurements and measurements after repair |

work as per BGV A3, compliance with the DIN VDE | |

inspection intervals is mandatory. |

Ongoing

Check the measured results of the equipment for plausibility.

Replace defective measuring instrumentation at the end of production.

Data bus:

Ongoing functional testing in operation.

Monthly

Test lamps and replace diodes if required.

Check the function of the system's internal measuring instrumentation by comparing the values during operation with the values displayed.

Check the function of the measuring instruments and accessory systems required for operation and servicing.

Check the interior area and equipment for moisture and, if necessary, establish the cause and dry the equipment.

Clean the interior areas of the compact station (operating area).

Every 6 months

Check the fastenings and function of the electrical connections of all components in the compact station.

Check the function of the fault current, differential current and fault voltage protective circuits.

Carry out recurrent measurements in accordance with DIN VDE 0105.

Check the axial ventilator for damage and whether it is working correctly (rotation), and repair or replace if necessary.

Check the axial ventilator and

Check the function of the overtemperature warning system by opening the sensor path.

Page 34 of 39 | 8000043213 BAL |