Control System Components

Chilled and Condenser Water Flow Interlock Circuits

Proof of chilled water flow for the evaporator is made by the closure of flow switch 5S1 and the closure of

auxiliary contacts 5K1 on terminals

auxiliary contacts 5K2 on terminals

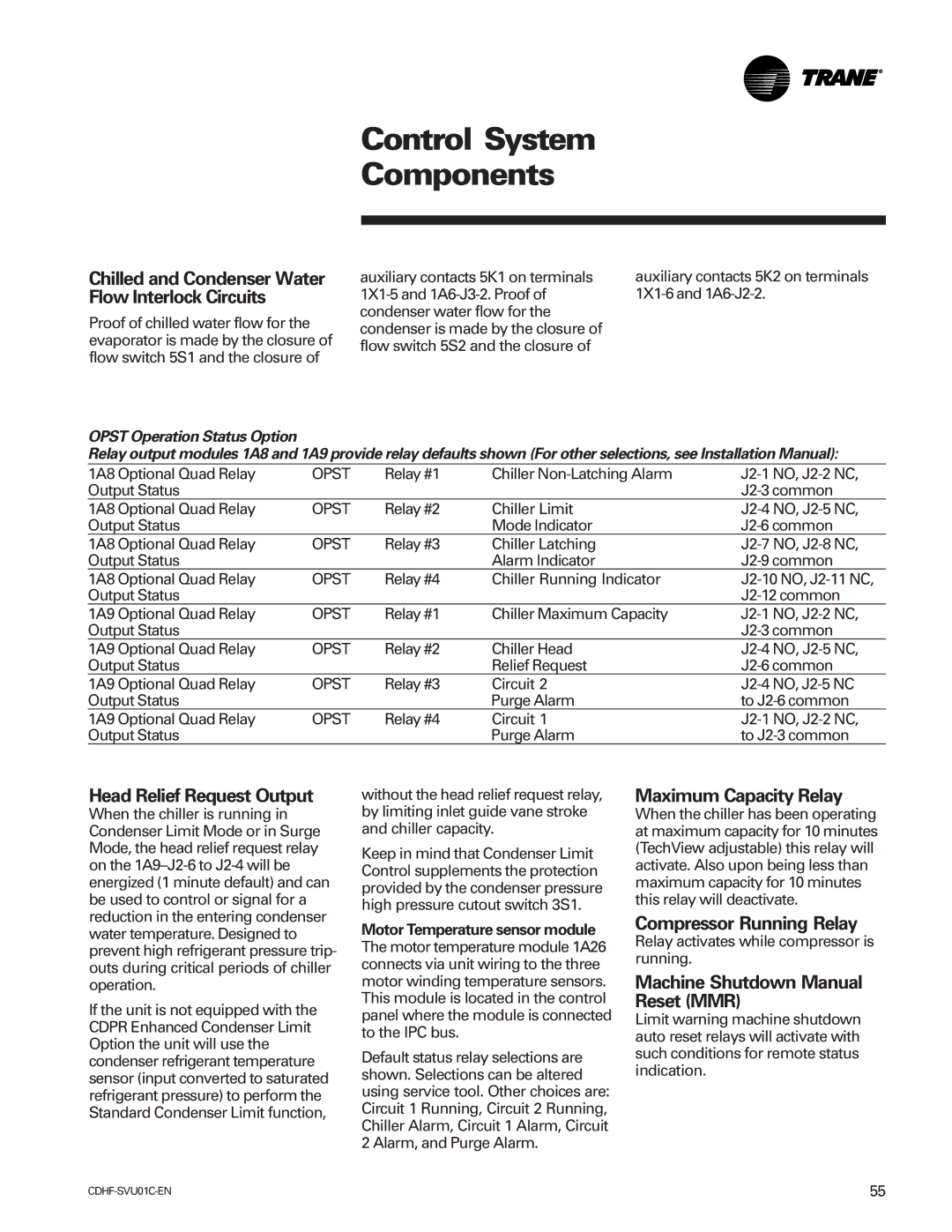

OPST Operation Status Option

Relay output modules 1A8 and 1A9 provide relay defaults shown (For other selections, see Installation Manual):

1A8 Optional Quad Relay | OPST | Relay #1 | Chiller | |

Output Status |

|

|

| |

1A8 Optional Quad Relay | OPST | Relay #2 | Chiller Limit | |

Output Status |

|

| Mode Indicator | |

1A8 Optional Quad Relay | OPST | Relay #3 | Chiller Latching | |

Output Status |

|

| Alarm Indicator | |

1A8 Optional Quad Relay | OPST | Relay #4 | Chiller Running Indicator | |

Output Status |

|

|

| |

1A9 Optional Quad Relay | OPST | Relay #1 | Chiller Maximum Capacity | |

Output Status |

|

|

| |

1A9 Optional Quad Relay | OPST | Relay #2 | Chiller Head | |

Output Status |

|

| Relief Request | |

1A9 Optional Quad Relay | OPST | Relay #3 | Circuit 2 | |

Output Status |

|

| Purge Alarm | to |

1A9 Optional Quad Relay | OPST | Relay #4 | Circuit 1 | |

Output Status |

|

| Purge Alarm | to |

Head Relief Request Output

When the chiller is running in Condenser Limit Mode or in Surge Mode, the head relief request relay on the

If the unit is not equipped with the CDPR Enhanced Condenser Limit Option the unit will use the condenser refrigerant temperature sensor (input converted to saturated refrigerant pressure) to perform the Standard Condenser Limit function,

without the head relief request relay, by limiting inlet guide vane stroke and chiller capacity.

Keep in mind that Condenser Limit Control supplements the protection provided by the condenser pressure high pressure cutout switch 3S1.

Motor Temperature sensor module The motor temperature module 1A26 connects via unit wiring to the three motor winding temperature sensors. This module is located in the control panel where the module is connected to the IPC bus.

Default status relay selections are shown. Selections can be altered using service tool. Other choices are: Circuit 1 Running, Circuit 2 Running, Chiller Alarm, Circuit 1 Alarm, Circuit 2 Alarm, and Purge Alarm.

Maximum Capacity Relay

When the chiller has been operating at maximum capacity for 10 minutes (TechView adjustable) this relay will activate. Also upon being less than maximum capacity for 10 minutes this relay will deactivate.

Compressor Running Relay

Relay activates while compressor is running.

Machine Shutdown Manual Reset (MMR)

Limit warning machine shutdown auto reset relays will activate with such conditions for remote status indication.

55 |