Reflector Panel

Adjustment

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

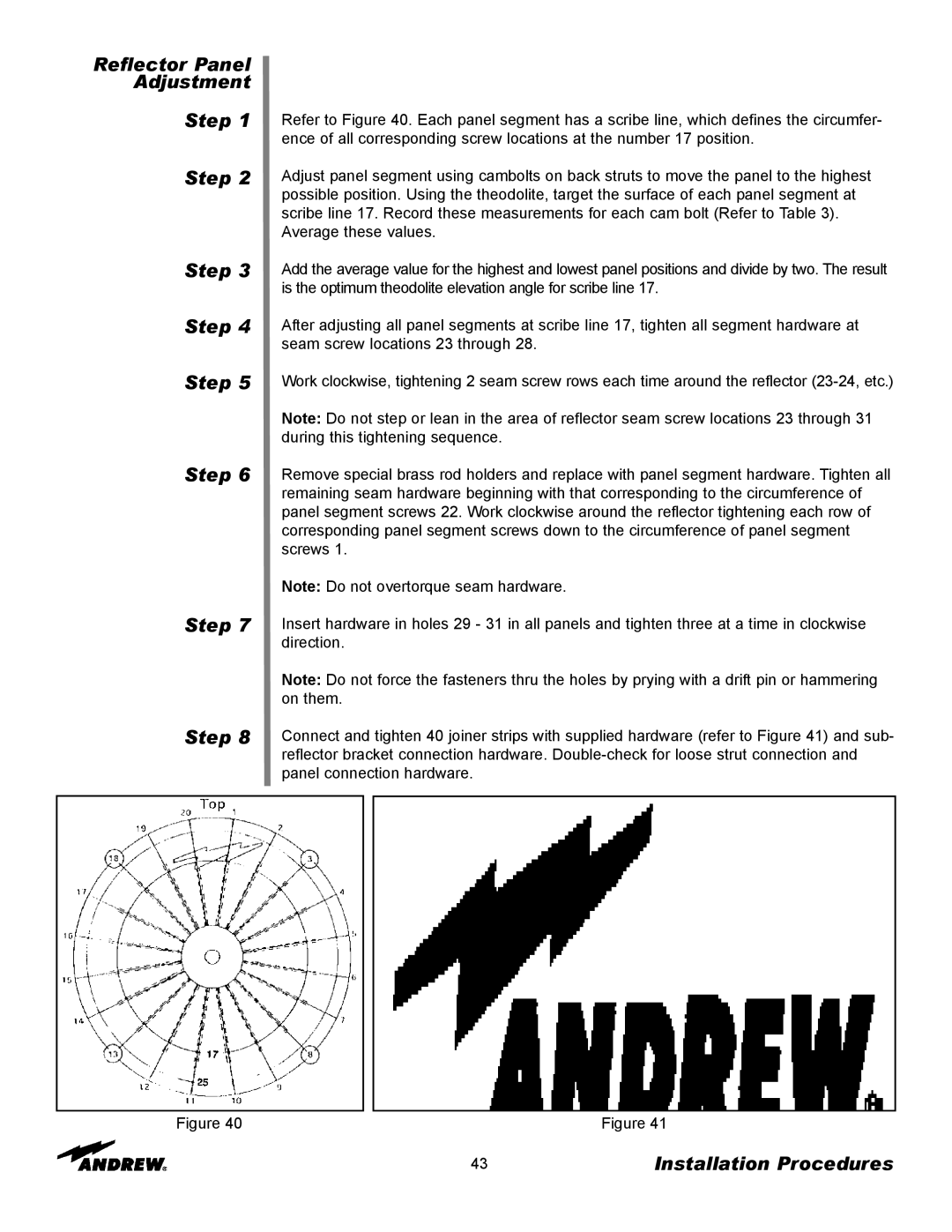

Refer to Figure 40. Each panel segment has a scribe line, which defines the circumfer- ence of all corresponding screw locations at the number 17 position.

Adjust panel segment using cambolts on back struts to move the panel to the highest possible position. Using the theodolite, target the surface of each panel segment at scribe line 17. Record these measurements for each cam bolt (Refer to Table 3). Average these values.

Add the average value for the highest and lowest panel positions and divide by two. The result is the optimum theodolite elevation angle for scribe line 17.

After adjusting all panel segments at scribe line 17, tighten all segment hardware at seam screw locations 23 through 28.

Work clockwise, tightening 2 seam screw rows each time around the reflector

Note: Do not step or lean in the area of reflector seam screw locations 23 through 31 during this tightening sequence.

Remove special brass rod holders and replace with panel segment hardware. Tighten all remaining seam hardware beginning with that corresponding to the circumference of panel segment screws 22. Work clockwise around the reflector tightening each row of corresponding panel segment screws down to the circumference of panel segment screws 1.

Note: Do not overtorque seam hardware.

Insert hardware in holes 29 - 31 in all panels and tighten three at a time in clockwise direction.

Note: Do not force the fasteners thru the holes by prying with a drift pin or hammering on them.

Connect and tighten 40 joiner strips with supplied hardware (refer to Figure 41) and sub- reflector bracket connection hardware.

Figure 40 | Figure 41 |

43 | Installation Procedures |