GTS1031 specifications

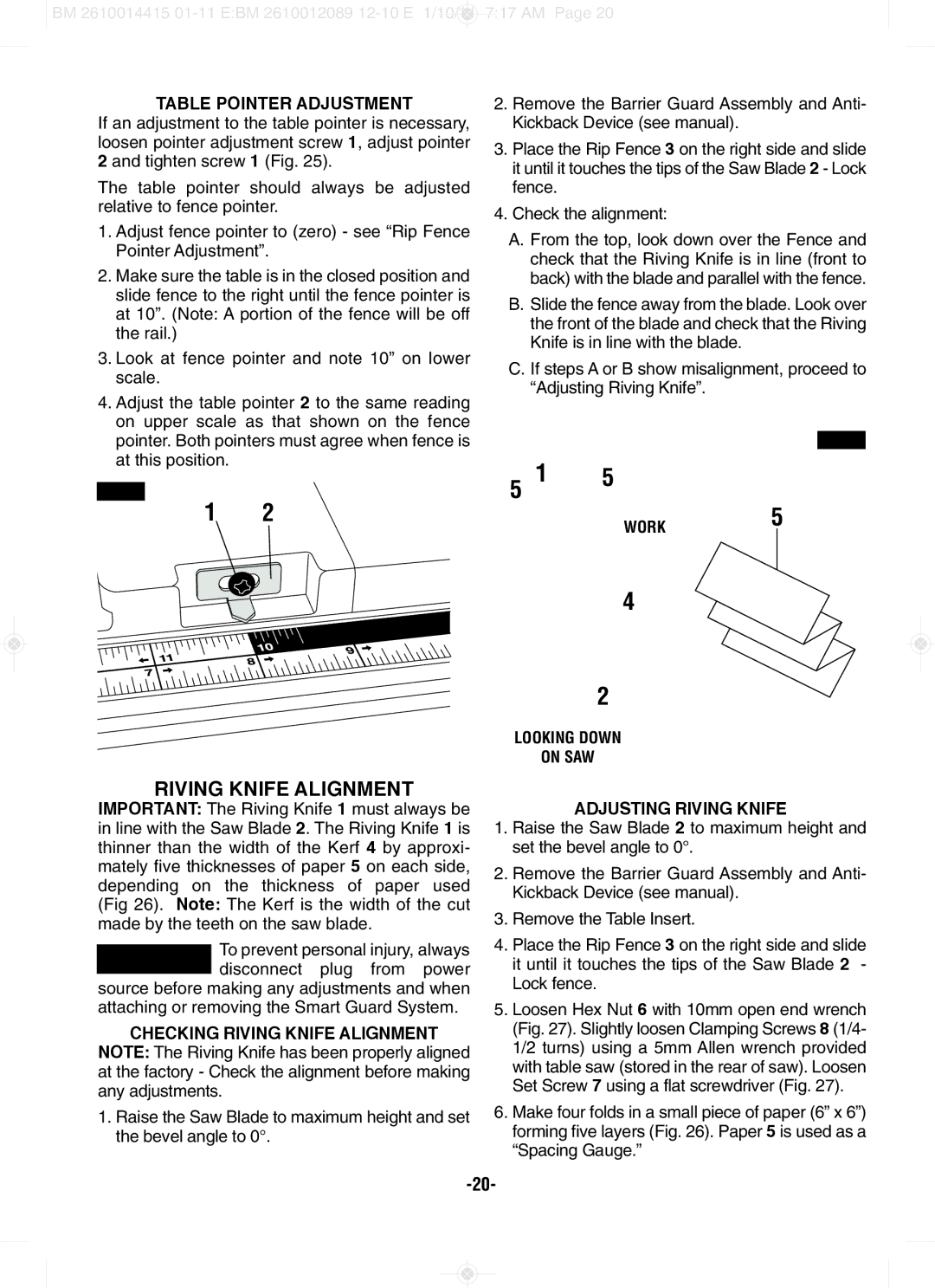

The Bosch Power Tools GTS1031 is a compact job site table saw designed to deliver precision cutting in a portable format. This powerful saw is equipped with a robust 15-amp motor that can easily handle a wide variety of applications, making it an excellent choice for contractors and DIY enthusiasts alike.One of the standout features of the GTS1031 is its Smart Guard System. This integrated safety feature includes a modular blade guard, riving knife, and anti-kickback pawls. The blade guard helps protect the user from accidental contact with the blade, while the riving knife reduces the risk of kickback during operation. The entire system is designed to be easy to install and adjust, promoting both safety and efficiency on the job.

The GTS1031 boasts a portable, lightweight design that weighs just 52 pounds. This makes it easy to transport, set up, and store. Its foldable stand provides a stable base while offering simple setup and breakdown without the need for additional tools. The compact size of the saw, along with its sturdy construction, makes it extremely convenient for use in tight spaces or on busy job sites.

Another notable characteristic of the GTS1031 is its cutting capacity. With a 10-inch blade, it can make cuts up to 26 inches wide with a depth of 3.5 inches at 90 degrees and 2.5 inches at 45 degrees. The precision machined aluminum table ensures accurate cuts and durability, while the integrated measurements allow for easy adjustments and repeatability.

The saw features an onboard storage system for its accessories, ensuring that everything needed for operation is within arm's reach. This organization helps users stay efficient, reducing downtime during projects. The table saw is also designed for easy blade changes, minimizing interruption and allowing users to switch between different types of blades based on their cutting needs.

With its blend of power, portability, and safety features, the Bosch Power Tools GTS1031 stands out as a reliable choice for both professionals and hobbyists. Its emphasis on precision and user-friendly design makes it an indispensable tool for a wide range of applications, from framing to fine woodworking.