Important Safety Instructions

Achtung

«УКАЗАНИЯ ПО Технике БЕЗОПАСНОСТИ»

For Users in UK, EIRE, Malta and Cyprus only

Connecting Plugs and Main Power / Sewing Light Switch

Please Read Before Using this Machine

Bitte VOR Benutzung Dieser Maschine Lesen

ПОЖАЛУЙСТА,ПРОЧИТАЙТЕПЕРЕДНАЧАЛОМЭКСПЛУАТАЦИИМАШИНЫ

Table of Contents

Inhalt

Оглавление

Не входящие в пуговичный зажим

Principal Parts

Balance Wheel

Handrad

Нижней

Для настройки натяжения верхней нитки

6043

Accessories

Optional Accessories

Optionales Zubehör

Дополнительные принадлежности

Notizen

Примечание

Connecting Plugs

Operating Your Sewing Machine

Vorsicht

Kabelanschlüsse

Предостережение

Netz- und Nählichtschalter

Main Power/Sewing Light Switch

Главный выключатель питания Освещения зоны строчки

Foot Controller

Fußanlasser

Ножной контроллер

Ножной контроллер

Checking the Needle

Replacing the Needle

Nadel austauschen

Nadel prüfen

Проверка иглы

Changing the Presser Foot

Nähfuß wechseln

Замена нажимной лапки

SNAP-ON Type

Flat Bed Attachment

Anschiebetisch mit Zubehörfach

Платформа-приставка

Various Controls

Pattern Selection Dial

Stichmuster-Einstellrad

Ручка выбора типа стежка

Ручка выбора типа стежка Номер стежка

Ручка регулирования длины стежка

Pattern Stitch Name Preset Width Recommended Instruction

Manual

Rampart Stitch Triple Stretch Stitch

Step Automatuc Buttonhole

Empfohlene Einstellwerte

Anleitung

Modell XL-6050, XL-6051, XL-6052, XL-6053

OVERLOCK-SCHRÄGSTICH

Номер Страницы

Строчка Наименование Стежка Заданная Ширина

Руководства

Модели XL-6050, XL-6051, XL-6052, XL-6053

Наклонная Оверлочная

Stitch Length Dial

Higher the NUMBER, the Longer the Stitch

Stichlängen-Einstellrad

Ручка регулирования длины стежка

Ручка регулирования длины стежка Длина Частые → SS Редкие

Поверните ручку влево за0на позицию SS SS Фиксированная 2,5

Rückwärtstaste

Reverse Sewing Lever

Рычаг реверсирования строчки

Converting to Free-arm Style

Umbau auf Freiarm

Переключение на режим Free-arm

Сдвиньте платформу-приставку Платформа-приставка

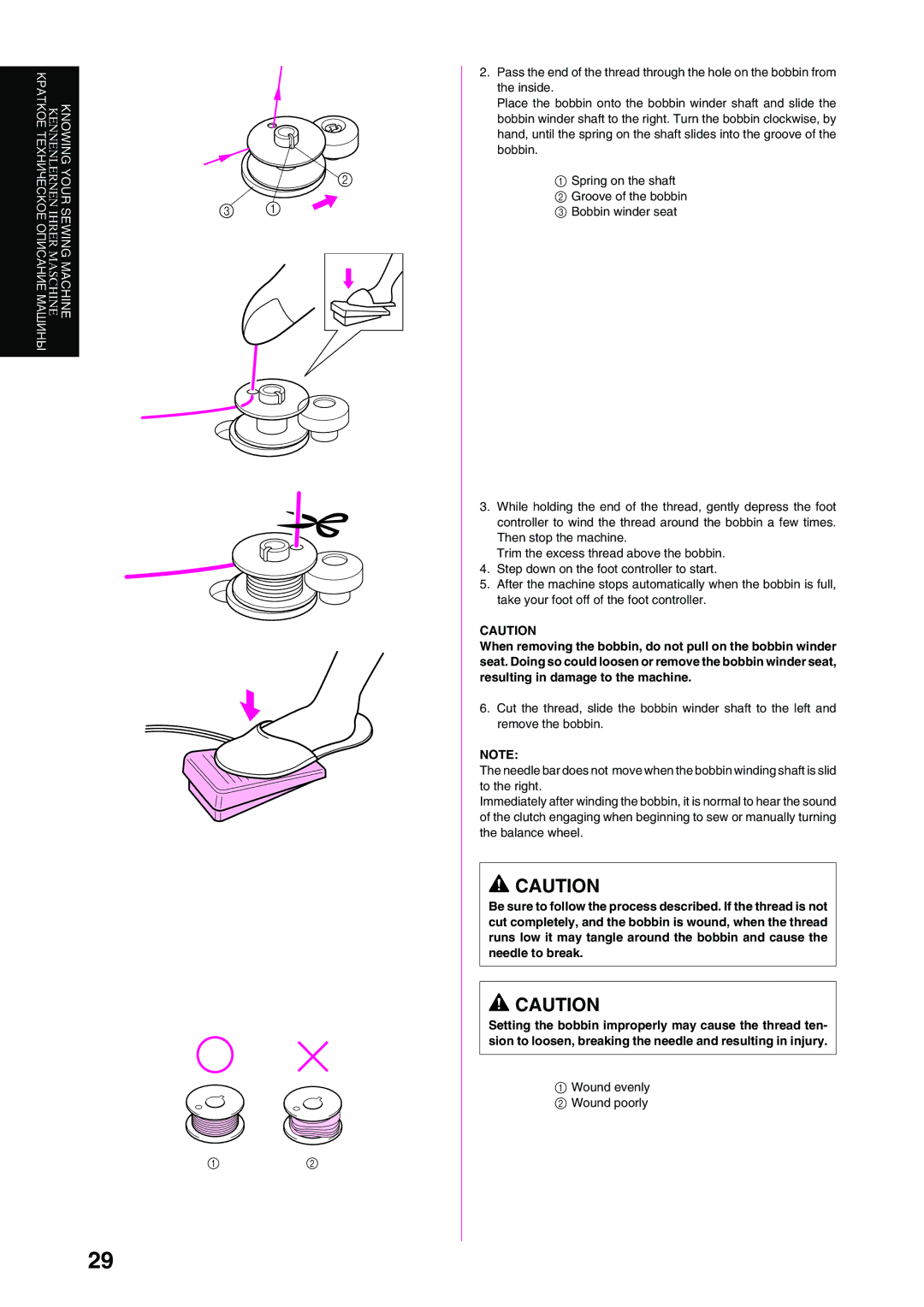

Aufspulen

Намотка ниток на шпульку

Wound evenly Wound poorly

Сместите этот вал вправо. Поверните шпульку рукой по

Шпульке Установите шпульку на вал мотального механизма и

Ровная намотка Неправильная намотка

Lower Threading

Unterfadenführung

Заправка нижней нитки

Сдвиньте кнопку и откройте крышку Скользящая кнопка Крышка

Пока крышка не встанет на место со щелчком

Upper Threading

Oberfadenführung

Заправка верхней нитки

Heraufholen des Unterfadens

Drawing Up Lower Thread

Вытягивание нижней нитки

Nähen mit Doppelnadel

Twin Needle Sewing

Двухигольная строчка

Установкадополнительноговставногокатушечногостержня

Установка Двойной Иглы

Заправка Ниток В Двойную Иглу

Thread Tension

Fadenspannung

Натяжение ниток

Hinweis

FABRIC/THREAD/NEEDLE Combinations

75/11 90/14

65/9 75/11

Тяжелые ткани

90/14 100/16

Please Read Before Sewing

Geradstich

Straight Stitching

Прямой стежок

Nähbeginn

Changing Sewing Direction

Finishing Sewing

Изменение Направления Строчки

Завершение Строчки

Removing the Material from the Machine

TOP Stitching and Stretch Materials

Снятие Прошитой Ткани С Машины

Верхний Стежок И Эластичные Материалы

Zigzag Stitching

Zickzackstich

Зигзагообразный стежок

Зигзаогообразный Стежок

Blindsaumstich

Blind Hem Stitching

Потайной подрубочный шов

Shell Tuck Stitching

Biesenstich

Подшивочная строчка

Elastic Stitching

Elastikstich

Эластичная строчка

Elastische Schrittnaht

Double Action Stitching

Стежок с двойным эффектом

Строчка-мостик Фиксир Стежок рампарт

Bogennaht

Scallop Stitching

Строчка-елочка

Стежок Длина стежка Строчка-елочка

Decorative Stitching

Dekorstiche

Декоративный стежок

Бисерный стежок Стреловидный стежок

Patchwork

Patchwork

Лоскутное шитье

Позиция формирования первого стежка

Overedge Stitching

Ketteln & Versäubern

Обметочный стежок

Строчка «Гребешок» Фиксир

Feather Stitching

Triple Zigzag Stretch Stitching

Перистый стежок

Тройная трикотажная строчка «зигзаг»

Making a Buttonhole For 1-step BH Type

Making a Buttonhole

Knopfloch nähen Für 1-Stufen-Knopfloch BH-Typ

Обметывание петель

Knopfloch Nähen

Обработка Петли

Knöpfe die nicht in den Halter passen

Example

Making a Buttonhole For 4-step BH Type

Knopfloch nähen

Петли Чего поднимите ее над тканью Шаг

Задняя Сделайте 5-6 стежков Планка

Securing the Stitching and Cutting the BUTTON- Hole

Stiche Sichern UND Knopfloch Aufschneiden

Закрепление ШВА И Прорезка Петли

Buttonhole Fine Adjustment

Knopfloch-Feineinstellung

Тонкая наст ойка для обметывания петель

Wenn das Knopfloch nicht richtig genäht wird

Button Sewing

Knöpfe annähen

Ишивание пуговиц

Фикси Лапка зигзаг

Zipper Insertion

Gathering

Einnähen eines Reißverschlusses

Reffen

Вшивание застежек-молний

Об аботка сбо ок

Darning

Stopfen

Штопка

Любая

Appliqués

Applizieren

Аппликации

Стежок Длина стежка Ши ина стежка

Monogramming Embroidering

Preparing for Monogramming and Embroidering

Monogramming

Embroidering

Изготовление Монограмм

Monogramme und Stickarbeiten

Вышивание

Using the Walking Foot

Optional Accessories

Einsatz des Obertransporteurs

Эта лапка очень полезна п и сшивании таких мате иалов

Optional Accessories

Using the Spring-action Quilting Foot

Einsatz des Stopffußes

Использование лапки штопки

Стежок Длина стежка

Озетки Поднимите иглу и нажимную лапку

Using the 1/4-Inch Quilting Foot

Einsatz des Patchworkfuß

Использование нап авляющей Лапки 1/4 дюйма 6,5 мм

Changing the Light Bulb

Nählichtlampe auswechseln

Замена лампочки освещения

Отсоедините штепсель шну а питания от озетки

Отвинтите винт к епления к ышки с об атной сто оны

Cleaning

Чистка машины

Reinigung

Затем поднимите пластину и снимите ее с машины

Performance Check List

Removed from outlet

Checkliste

Transpor Langsam Tiert

Läuft Nicht AN

Нет

Типу опе ации

Неп авильная

Комбинация номе

Штепсель шну а

Неп авильно

Озетку

Нет Неп авильная Комбинация номе

Maschine verpacken

Repacking the Machine

Пе еупаковка машины

Inch Quilting Foot

Nadel

Деко ативный под убочный стежок

Зап авка ве хней нитки

Лапка для вшивания застежек-молний Лапка штопки-вышивки

Нап авляющая лапка 1/4 дюйма 6,5 мм

![]() CAUTION

CAUTION![]() CAUTION

CAUTION