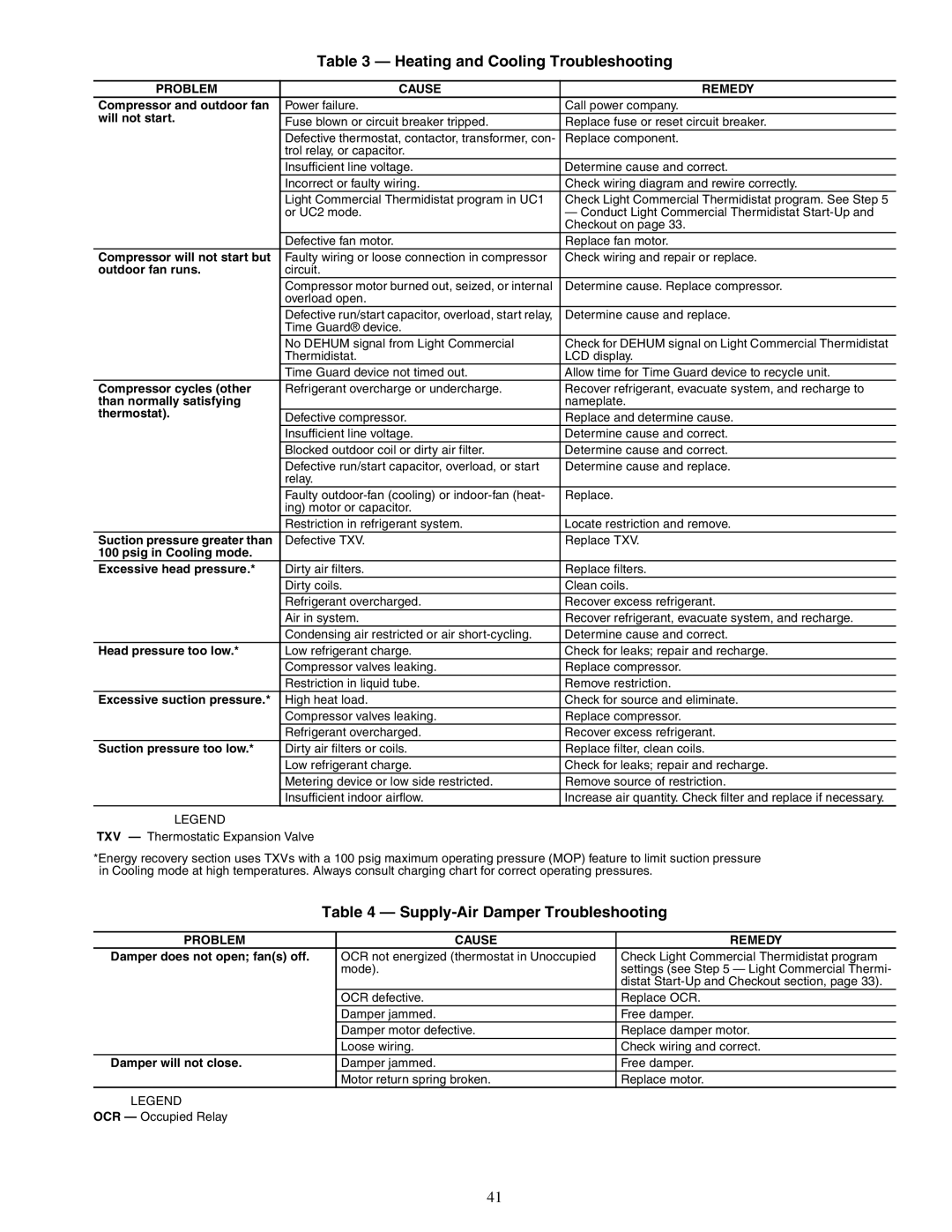

Table 3 — Heating and Cooling Troubleshooting

PROBLEM | CAUSE | REMEDY | |

Compressor and outdoor fan | Power failure. | Call power company. | |

will not start. |

|

| |

Fuse blown or circuit breaker tripped. | Replace fuse or reset circuit breaker. | ||

| |||

| Defective thermostat, contactor, transformer, con- | Replace component. | |

| trol relay, or capacitor. |

| |

| Insufficient line voltage. | Determine cause and correct. | |

| Incorrect or faulty wiring. | Check wiring diagram and rewire correctly. | |

| Light Commercial Thermidistat program in UC1 | Check Light Commercial Thermidistat program. See Step 5 | |

| or UC2 mode. | — Conduct Light Commercial Thermidistat | |

|

| Checkout on page 33. | |

| Defective fan motor. | Replace fan motor. | |

Compressor will not start but | Faulty wiring or loose connection in compressor | Check wiring and repair or replace. | |

outdoor fan runs. | circuit. |

| |

| Compressor motor burned out, seized, or internal | Determine cause. Replace compressor. | |

| overload open. |

| |

| Defective run/start capacitor, overload, start relay, | Determine cause and replace. | |

| Time Guard® device. |

| |

| No DEHUM signal from Light Commercial | Check for DEHUM signal on Light Commercial Thermidistat | |

| Thermidistat. | LCD display. | |

| Time Guard device not timed out. | Allow time for Time Guard device to recycle unit. | |

Compressor cycles (other | Refrigerant overcharge or undercharge. | Recover refrigerant, evacuate system, and recharge to | |

than normally satisfying |

| nameplate. | |

thermostat). | Defective compressor. | Replace and determine cause. | |

| |||

| Insufficient line voltage. | Determine cause and correct. | |

| Blocked outdoor coil or dirty air filter. | Determine cause and correct. | |

| Defective run/start capacitor, overload, or start | Determine cause and replace. | |

| relay. |

| |

| Faulty | Replace. | |

| ing) motor or capacitor. |

| |

| Restriction in refrigerant system. | Locate restriction and remove. | |

Suction pressure greater than | Defective TXV. | Replace TXV. | |

100 psig in Cooling mode. |

|

| |

Excessive head pressure.* | Dirty air filters. | Replace filters. | |

| Dirty coils. | Clean coils. | |

| Refrigerant overcharged. | Recover excess refrigerant. | |

| Air in system. | Recover refrigerant, evacuate system, and recharge. | |

| Condensing air restricted or air | Determine cause and correct. | |

Head pressure too low.* | Low refrigerant charge. | Check for leaks; repair and recharge. | |

| Compressor valves leaking. | Replace compressor. | |

| Restriction in liquid tube. | Remove restriction. | |

Excessive suction pressure.* | High heat load. | Check for source and eliminate. | |

| Compressor valves leaking. | Replace compressor. | |

| Refrigerant overcharged. | Recover excess refrigerant. | |

Suction pressure too low.* | Dirty air filters or coils. | Replace filter, clean coils. | |

| Low refrigerant charge. | Check for leaks; repair and recharge. | |

| Metering device or low side restricted. | Remove source of restriction. | |

| Insufficient indoor airflow. | Increase air quantity. Check filter and replace if necessary. |

LEGEND

TXV — Thermostatic Expansion Valve

*Energy recovery section uses TXVs with a 100 psig maximum operating pressure (MOP) feature to limit suction pressure in Cooling mode at high temperatures. Always consult charging chart for correct operating pressures.

Table 4 — Supply-Air Damper Troubleshooting

PROBLEM | CAUSE | REMEDY |

Damper does not open; fan(s) off. | OCR not energized (thermostat in Unoccupied | Check Light Commercial Thermidistat program |

| mode). | settings (see Step 5 — Light Commercial Thermi- |

|

| distat |

| OCR defective. | Replace OCR. |

| Damper jammed. | Free damper. |

| Damper motor defective. | Replace damper motor. |

| Loose wiring. | Check wiring and correct. |

Damper will not close. | Damper jammed. | Free damper. |

| Motor return spring broken. | Replace motor. |

LEGEND |

|

|

OCR — Occupied Relay |

|

|

41