2 Flavor, 4 Flavor specifications

Cornelius 4 Flavor and 2 Flavor dispensers are innovative beverage dispensing systems designed to meet the diverse needs of foodservice operators, bars, and restaurants. These sophisticated machines offer a unique solution by providing multiple flavors of drinks from a single unit, enhancing customer experience and boosting sales.One of the standout features of the Cornelius dispensers is their ability to serve multiple flavors simultaneously. The 4 Flavor model can dispense four different soft drink flavors, while the 2 Flavor model caters to establishments looking for a more streamlined option with two flavors. This flexibility allows businesses to cater to a varied clientele and adapt to seasonal or promotional offerings.

The technology behind these dispensers is based on advanced carbonation and mixing systems, ensuring a consistent and high-quality beverage every time. They utilize a patented blend of CO2 and syrup to create a perfect mix that maintains the right balance of flavor and carbonation. Both models also include user-friendly touch controls, allowing staff to easily switch between flavors and adjust servings.

Another important characteristic of the Cornelius dispensers is their energy efficiency. Designed with the latest eco-friendly technologies, they consume less power than traditional systems without compromising performance. The compact design not only saves energy but also helps in maximizing space in commercial settings.

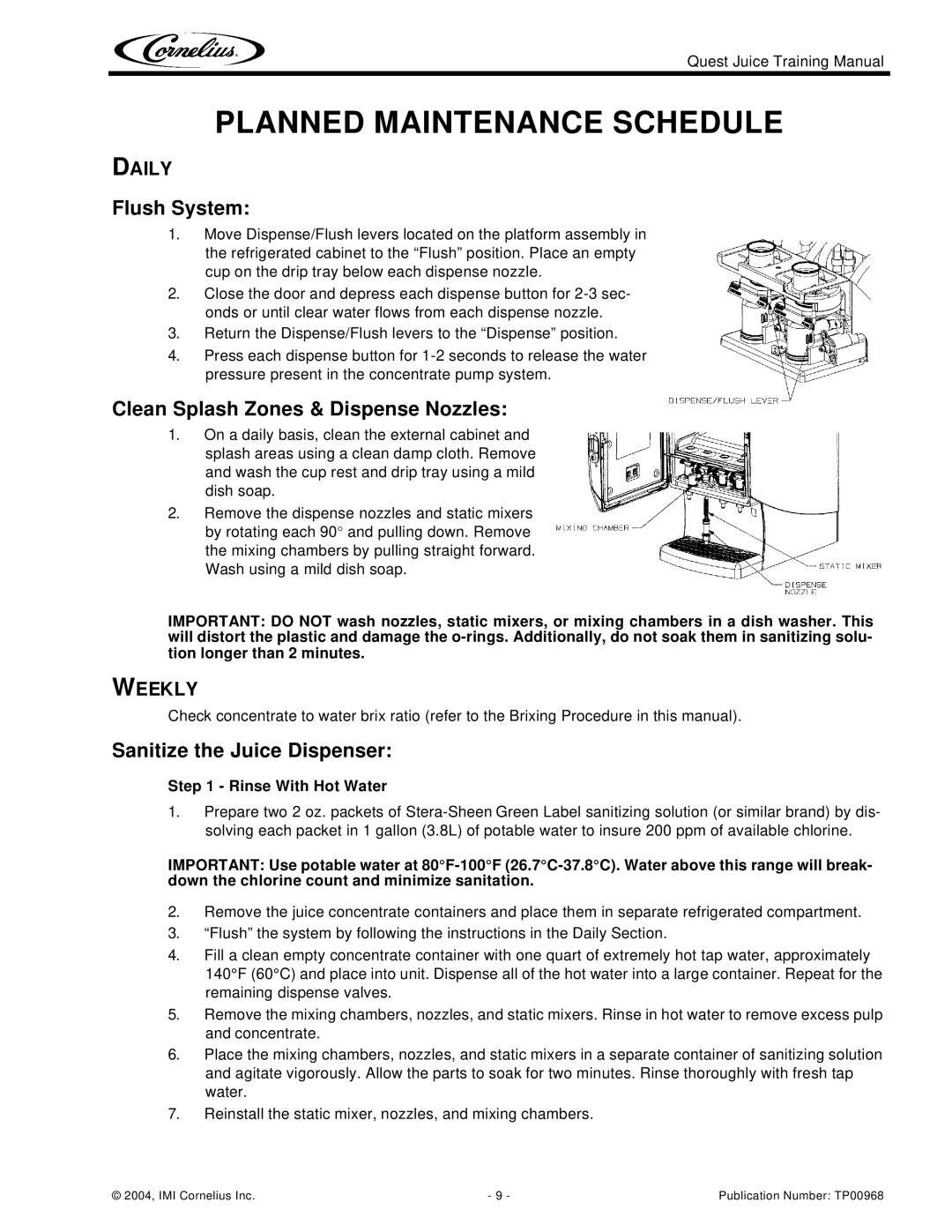

In terms of maintenance, Cornelius dispensers are designed for easy cleaning and service. The components are accessible, enabling quick troubleshooting and minimal downtime. This is crucial for busy environments where efficiency is paramount.

With customizable options, businesses can tailor their beverage offerings to match their branding and customer preferences. Both models allow for different syrup choices and can accommodate specialty beverages, including flavored iced teas or lemonades.

In summary, Cornelius 4 Flavor and 2 Flavor dispensers represent a significant advancement in beverage dispensing technology. Their multi-flavor capabilities, user-friendly design, energy efficiency, and ease of maintenance make them an ideal choice for foodservice operations looking to enhance their beverage service while maximizing profitability.