VENTING INSTALLATION INSTRUCTIONS | 9 |

Installation Planning (Cont.) |

VENTING INSTALLATION

INSTRUCTIONS

Continued

INSTALLATION PLANNING

There are two basic types of

•Horizontal Termination

•Vertical Termination

Horizontal Termination Installation

IMPORTANT: Horizontal square terminations require only inner portion of wall firestop. Horizontal installation using round termina- tion require exterior portion of wall firestop (see Figure 18, page 11).

1. Set the fireplace in its desired location and determine the route |

your horizontal venting will take. Do not secure the fireplace |

until all venting has been installed. Some installations require |

sliding the fireplace in and out of position to make final venting |

connections.Figures19through25onpages11through13show |

different configurations for venting with horizontal termina- |

tion that will help you decide which application best suits your |

installation. Check to see if wall studs or roof rafters are in the |

path of your desired venting route. If they are, you may want |

to adjust the location of the fireplace. |

2. Direct vent pipe sections and components are designed with |

special |

locking lugs (indentations). These lugs will slide straight into |

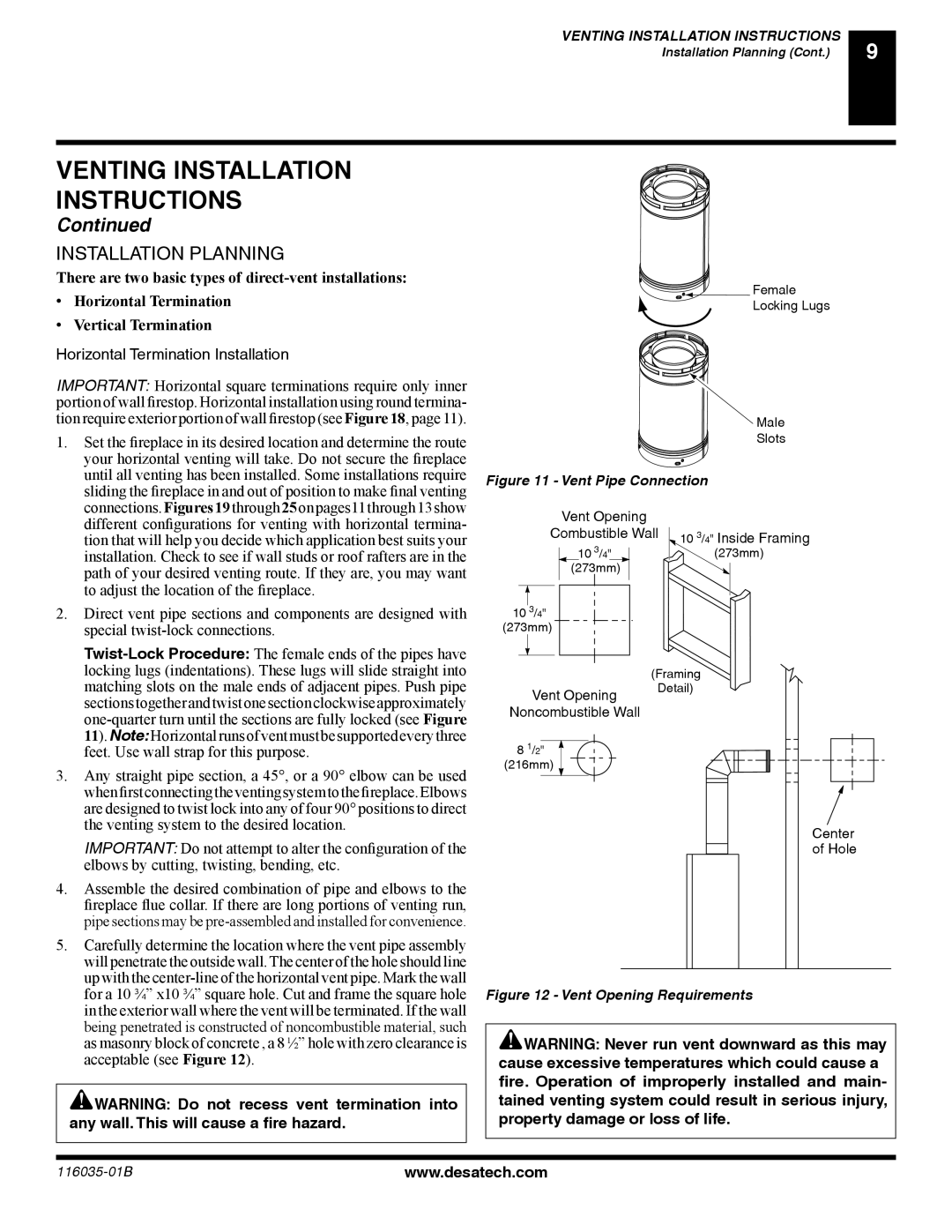

Female

Locking Lugs

Male

Slots

Figure 11 - Vent Pipe Connection

Vent Opening

Combustible Wall ![]() 10 3/4" Inside Framing

10 3/4" Inside Framing

10 3/4"(273mm) (273mm)

10 3/4" (273mm)

(Framing

matching slots on the male ends of adjacent pipes. Push pipe |

sectionstogetherandtwistonesectionclockwiseapproximately |

Vent Opening

Detail)

11).Note:Horizontalrunsofventmustbesupportedeverythree |

feet. Use wall strap for this purpose. |

3. Any straight pipe section, a 45°, or a 90° elbow can be used |

whenfirstconnectingtheventingsystemtothefireplace.Elbows |

are designed to twist lock into any of four 90° positions to direct |

the venting system to the desired location. |

IMPORTANT: Do not attempt to alter the configuration of the |

elbows by cutting, twisting, bending, etc. |

4. Assemble the desired combination of pipe and elbows to the |

fireplace flue collar. If there are long portions of venting run, |

pipe sections may be |

5. Carefully determine the location where the vent pipe assembly |

will penetrate the outside wall. The center of the hole should line |

up with the |

for a 10 ¾” x10 ¾” square hole. Cut and frame the square hole |

in the exterior wall where the vent will be terminated. If the wall |

being penetrated is constructed of noncombustible material, such |

as masonry block of concrete , a 8 ½” hole with zero clearance is |

acceptable (see Figure 12). |

![]() WARNING: Do not recess vent termination into any wall. This will cause a fire hazard.

WARNING: Do not recess vent termination into any wall. This will cause a fire hazard.

Noncombustible Wall

8 1/2"

(216mm)

Center

of Hole

Figure 12 - Vent Opening Requirements

![]() WARNING: Never run vent downward as this may cause excessive temperatures which could cause a fire. Operation of improperly installed and main- tained venting system could result in serious injury, property damage or loss of life.

WARNING: Never run vent downward as this may cause excessive temperatures which could cause a fire. Operation of improperly installed and main- tained venting system could result in serious injury, property damage or loss of life.

www.desatech.com |