D55690, D55695

Pump Air Intake Filter B. Engine Air Filter

Air Compressor

D55695

Specifications

Pump Specifications

Engine Specifications

Hot Surfaces

What can happen How to prevent it

Definitions Safety Guidelines

Important Safety Instructions

Save these instruction

What can happen

Transporting or storing

Fly apart, and could result in serious injury

Attachments & accessories

Tires

Attempting maintenance

Always wear certified safety

Maintenance until unit has

Equipment Ansi Z87.1 eye

Moving parts such as

By a DeWALT factory service

Service center

Your clothing

Important Safety Instructions for All Battery Packs

Read all Instructions

Specific Safety instructions for Lithium Ion Li-Ion

Rbrc Seal

25 ft 50 ft 75 ft 100 ft 125 ft 150 ft 175 ft

Important Safety Instructions for all Battery Chargers

Wire Size AWG

Do not operate charger with damaged cord or plug

Indicator Light Operation

Using Automatic Tune-Up Mode

Charging Procedure

Chargers

Problem Power Line

Charge Indicators

Hot/cold Pack DelaY

Leaving the battery pack in the charger

Safety Valve

Features

Storage Recommendations

AIR Tank Drain Valve

Assembly Fig

AIR Intake Filter

Regulated Pressure Gauge

Location

Compatibility

Transporting

Lifting

Preparation For Use Pre-Start Checklist Fig

Initial Set-up Fig

Kg Do not move or lift without assistance

Procedure

Break-in Procedure This procedure is required

Recoil Start

Follow Pre-Start Checklist under Preparation for Use

Operating Procedures Start-up Fig

Turn the engine START/RUN/OFF switch C to the RUN position

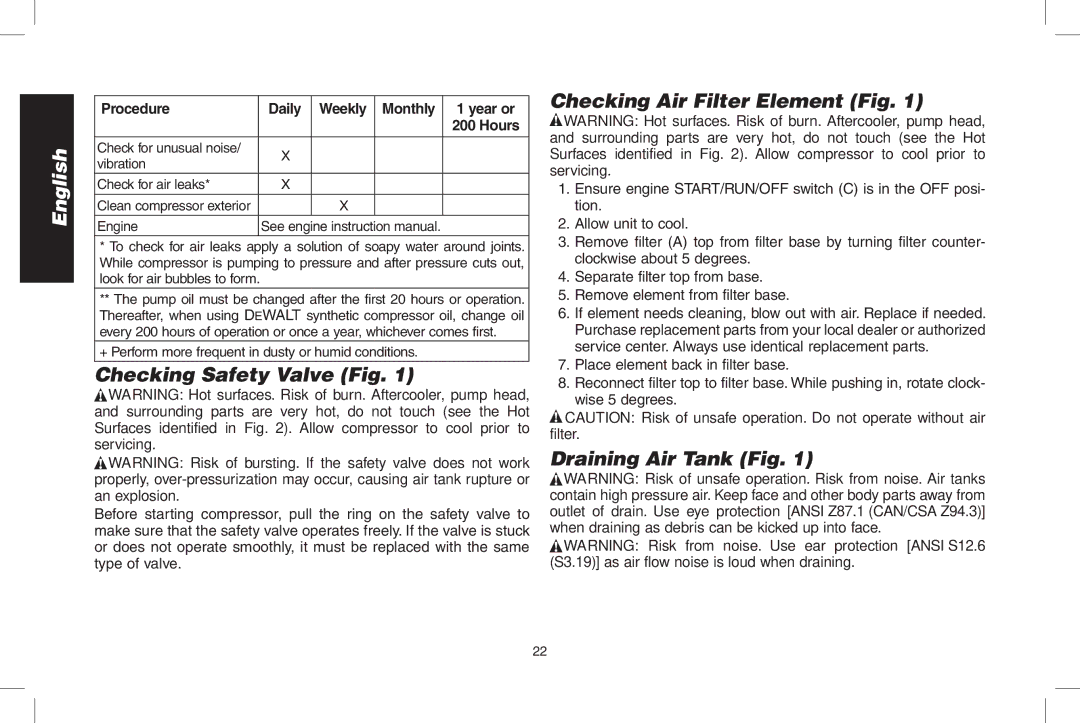

Procedure Daily Weekly Monthly Year or

Maintenance

Maintenance Chart

Shut-down

Checking Air Filter Element Fig

Checking Safety Valve Fig

Draining Air Tank Fig

Compressor Pump Oil Fig

Air tank causing a risk of air tank rupture

Checking oil Changing oil

Checking Belt Tension Fig

Adjusting Belt Tension

Pulley and Flywheel Alignment

Repairs

Accessories Service Information

Full One Year Warranty

Date and Place of Purchase

Glossary

Troubleshooting Guide

Problem Code

Code Possible cause

Troubleshooting Codes

Possible Solution

Erwise modify air tank or it will weaken. The air tank can

See Motor Pulley/Flywheel Alignment under Maintenance

Compressor Pump Oil under Maintenance

Regulator open Engine fuel tank empty

Procedure

Push knob in to lock in place

Compresseur d’air

Surfaces chaudes

Caractéristiques techniques de la pompe

Caractéristiques techniques du moteur

Fiche technique

Mineures ou modérées

Définitions lignes directrices en Matière de sécurité

Directives de sécurité importantes

Composer Sans Frais LE 1-800-4-DeWALT

CE QUI Peut SE Produire

Du compresseur ne devrait

Installer correctement des

Filtres convenables et un

Jamais être utilisé pour

CE QUI Peut SE Produire Comment L’ÉVITER

Pneus

Attachements et accessoires

Le manomètre pour empêcher un surgonflage

CSA Z94.3 munie d’écrans

Des accessoires

De sécurité homologué

Compresseur

Endommagés ou retirés

Ne jamais utiliser le

Ou les couvercles sont

Garder les cheveux, les

Lire toutes les directives

Avertissement Risque d’incendie. Ne pas

Le sceau Srprc

Calibre AWG

25 pi

NE Jamais tenter de relier deux chargeurs ensemble

Procédure de charge

Utilisation du mode tune-up automatique

Chargeurs

Fonctionnement du voyant Voyants de charge

Problème avec le secteur

Remarques importantes pour le chargement

Fonction de suspension du bloc-piles chaud/froid

Bloc-piles laissé dans le chargeur

Démarrage Électrique

Recommandations d’entreposage

Caractéristiques

BLOC-PILES ET Chargeur DE 18 Volts

Soupape DE Purge DU Réservoir D’AIR

Soupape DE Sûreté

Filtre D’ADMISSION D’AIR

Manomètre DU Réservoir D’AIR

Assemblage fig

Emplacement

Compatibilité

Transport

Déplacement

REMARQUE

Réglage initial fig

Mode d’emploi Liste de vérification de pré-démarrage fig

Procédure de rodage La procédure suivante est requise

Démarrage à rappel

Démarrage électrique

Procédures de fonctionnement Démarrage fig

Régulateur sous Caractéristiques

Arrêt

Entretien

Étapes 3 à

Vérification de la soupape de sûreté fig

Programme d’entretien

Vérification des éléments du filtre d’air fig

Huile de la pompe du compresseur fig

Vidange du réservoir d’air fig

Vérification de l’huile

Vérification de la tension de la courroie Fig

Vidange d’huile

Réglage la tension de la courroie

Alignement de la poulie et du volant

Réparations

Accessoires Information sur les réparations

Garantie complète d’un 1 an

Glossaire

13, 14, 16, 19

Guide de dépannage

Problème Code

Sifflement

Code Cause possible

Est requis pour l’utilisation de l’accessoire

Codes de dépannage

Rompre ou d’exploser

Fixation bien serrées

Réglage de la tension de la courroie sous Entretien

Avertissement Risque d’éclatement. Des vibrations

Ne jamais utiliser l’appareil sans le support du raidisseur

Volant sous Entretien

Consulter la rubrique Alignement de la poulie-moteur

Compresseur sous Entretien

Ouverte

D55690A

Compresor de aire

Tapón de drenaje de aceite de la bomba

Superficies calientes

Especificaciones de la bomba

Especificaciones del motor

Especificaciones

Peligro Riesgo de explosión o incendio

Instrucciones de seguridad importantes

Guarde estas instrucciones

¿Qué puede suceder? Cómo evitarlo

Peligro Riesgo Respiratorio asfixia

Advertencia Riesgo de explosión

Neumáticos

¿Qué puede suceder?

Elementos y accesorios

Neumático

Advertencia Riesgo por piezas móviles

Advertencia Riesgo de operación insegura

Lea todas las instrucciones

Advertencia Riesgo de incendio. No guarde

Sin embargo, si el sello externo está roto

El sello Rbrc

Tamaño AWG del conductor

Utilización del modo Tune-Up automático

Pies 50 pies

Nunca intente conectar 2 cargadores juntos

Operación de la luz indicadora Indicadores de carga

Cargadores

Procedimiento de carga

Retraso por paquete caliente/frío

Notas importantes sobre la carga

Línea de potencia con problemas

Dejar el paquete de baterías en el cargador

Arranque Eléctrico

Recomendaciones con respecto al almacenamiento

Características

Paquete DE Baterías Y Cargador DE 18

Válvula DE Drenaje DEL Tanque DE Aire

Ensamblaje Fig

Filtro DE Entrada DE Aire

Manómetro Regulado

Compatibilidad

Lubricación y aceite

Lugar

Transporte

Áreas húmedas

Consideraciones sobre el ruido

Levantar la unidad

Configuración inicial Fig

Arranque de retroceso

Arranque eléctrico

Procedimientos operativos Puesta en marcha Fig

Apagado

Mantenimiento

Controlar el elemento del filtro de aire

Tabla de mantenimiento

Controlar la válvula de seguridad Fig

Procedimiento

Coloque el elemento nuevamente en la base del filtro

Drenar el tanque de aire Fig

Aceite de la bomba del compresor

Controlar el aceite

Controlar la tensión de la correa Fig

Cambio de aceite

OFF apagado Espere que la unidad

Ajustar la tensión de la correa

Alineación de la correa y el volante

Se enfríe Desconecte el cable de La bujía Drene Tanque Aire

Reparaciones

Accesorios

Información del servicio técnico

Póliza de Garantía

Garantía completa de un año

Excepciones

Glosario

Para Otras Localidades

Guía de detección de problemas

Problema Código

Solución Posible

Códigos de detección de problemas

Código Causa posible

Advertencia Riesgo de explosión. No perfore, suelde ni

Consulte Alineación de la polea y el volante en la sección

Tornillos de montaje se deben mantener ajustados

Que esté equipada con el soporte de la barra tensora

Mantenimiento

Consulte Aceite de la bomba del compresor en la sección

Tanque de combustible del motor vacío

Al de instrucciones del motor

JUN08 Part No. N000707

EWALT Industrial Tool Co., 701 Joppa Road, Baltimore, MD

Copyright 2008 D eWALT

![]() Warning: Hot surfaces. Risk of burn. Aftercooler, pump head, and surrounding parts are very hot, do not touch (see the Hot Surfaces identified in Fig. 2). Allow compressor to cool prior to servicing.

Warning: Hot surfaces. Risk of burn. Aftercooler, pump head, and surrounding parts are very hot, do not touch (see the Hot Surfaces identified in Fig. 2). Allow compressor to cool prior to servicing.![]() Warning: Risk of bursting. If the safety valve does not work properly,

Warning: Risk of bursting. If the safety valve does not work properly, ![]() Warning: Hot surfaces. Risk of burn. Aftercooler, pump head, and surrounding parts are very hot, do not touch (see the Hot Surfaces identified in Fig. 2). Allow compressor to cool prior to servicing.

Warning: Hot surfaces. Risk of burn. Aftercooler, pump head, and surrounding parts are very hot, do not touch (see the Hot Surfaces identified in Fig. 2). Allow compressor to cool prior to servicing.![]() CAUTION: Risk of unsafe operation. Do not operate without air filter.

CAUTION: Risk of unsafe operation. Do not operate without air filter.![]() Warning: Risk of unsafe operation. Risk from noise. Air tanks contain high pressure air. Keep face and other body parts away from outlet of drain. Use eye protection [ANSI Z87.1 (CAN/CSA Z94.3)] when draining as debris can be kicked up into face.

Warning: Risk of unsafe operation. Risk from noise. Air tanks contain high pressure air. Keep face and other body parts away from outlet of drain. Use eye protection [ANSI Z87.1 (CAN/CSA Z94.3)] when draining as debris can be kicked up into face.![]() Warning: Risk from noise. Use ear protection [ANSI S12.6 (S3.19)] as air flow noise is loud when draining.

Warning: Risk from noise. Use ear protection [ANSI S12.6 (S3.19)] as air flow noise is loud when draining.