XM Plural-Component Sprayers313289S

Contents

Manual Description

Related Manuals

Component Manuals in U.S. English

Fire and Explosion Hazard

Intrinsic Safety

Equipment Misuse Hazard

Location Category Key

Models

XM a XM B XM D XM C XM E

Approvals

Isocyanate Hazard

Overview

Material Self-Ignition

Moisture Sensitivity Isocyanates

Keep Components a and B Separate

Components a and B

Changing Materials

Lift Using a Hoist

Lift Using a Forklift

Before Repair

Location Proper Lifting of Sprayer

Relieve Pump Fluid Pressure

Pressure Relief Procedure

Relieve a and B Fluid Pressure

Flush Before Using Equipment

Flush Mixed Material

Flush

Flush Mix Manifold

Use Solvent Pump

Follow Pressure Relief Procedure,

Empty and Flush Entire System new sprayer or end of job

Procedure

Guidelines

Turn on heaters until fluid lines are clear of sol- vent

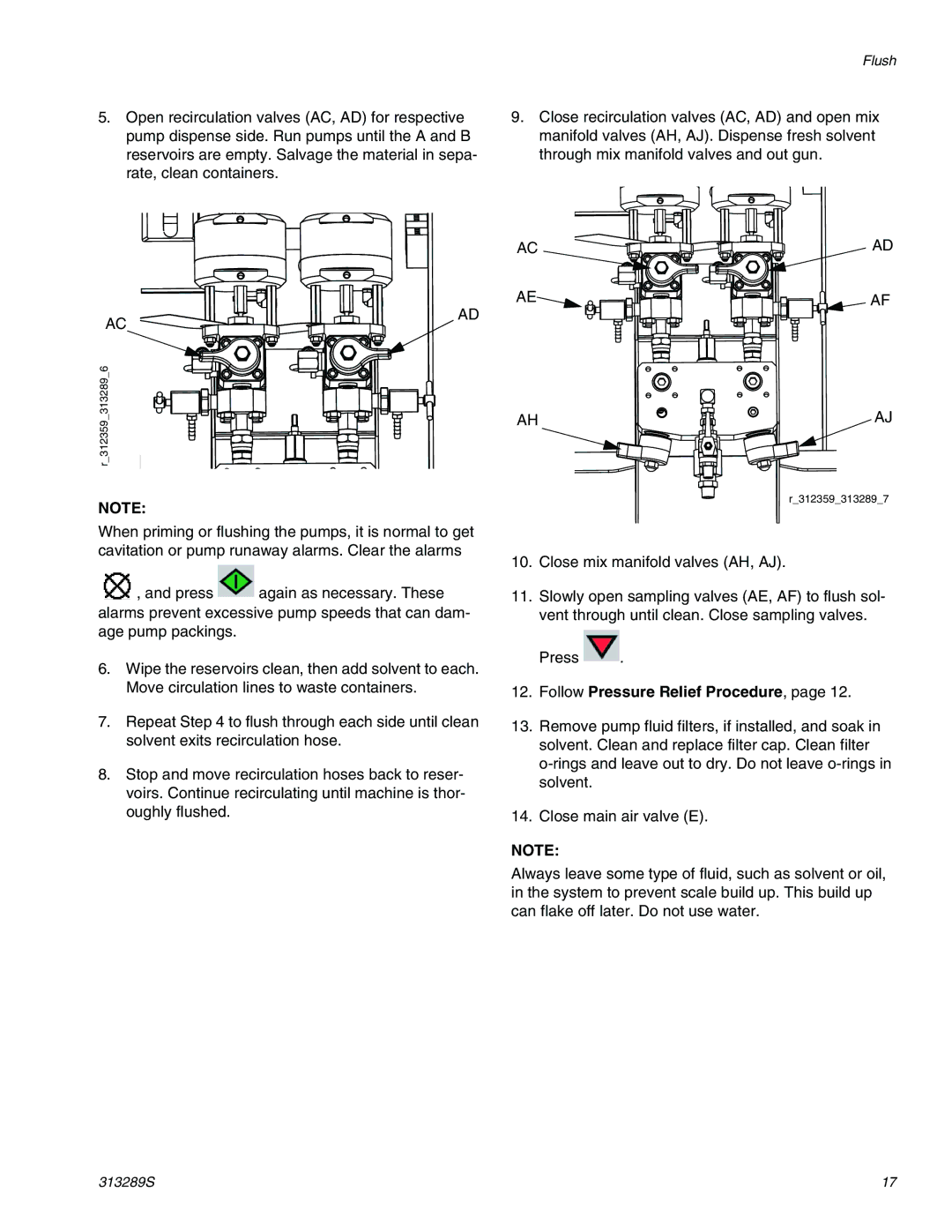

R3123593132896 R3123593132897

Relieve pressure. See Pressure Relief Procedure,

Cleaning Procedure

Shutdown Entire System

Flush Entire System new sprayer or end of job on

XM Setup and Troubleshooting Guide

Problem Cause Solution

Troubleshooting

See Appendix a in manual

Tor Power Supply Control Compo

View Alarms

Alarms

Diagnose Alarms

Clear Alarms

Alarm Code Alarm Problem When Active Cause Solution

Alarm Codes and Troubleshooting

See Pump Assembly,

Pump Test Daily Check Recommended

Optional User-Settable Maintenance Warnings

Optional User-Settable Spray Limits

Mode Control Logic Alarms

Possible Alarms by Mode

R2D

Stop

Alarm Code Key

LED Diagnostic Information

Module Status LED Signal Diagnosis Solution

What Alert Where

Replace Air Filter Element

Repair

Main Air Inlet Manifold Filter

Both Filters

Remove Shroud

User Interface/Control Box

Replace Solenoid Module

DVA DVB

Replace USB Module

Update USB Module Software

Load software. See Update USB Module Soft Ware

Replace Fluid Control Module FCM

Update Fluid Control Module FCM Software

Load software. See Update Fluid Control Module FCM Software

Display

Replace Alarm

Upgrade Software

Replace Display

Replace Display Battery

Replace Front Panel

Wall Power Supply Control Components

Replace Power Supply Module

Alternator Module Repair

Alternator Power Supply Control Components

FCM

USB

Replace Alternator Regulator

Air Controls

Gauge 326 319 330 340 331

Mix Manifold Assembly

Fluid Control Assembly

Dosing Valve Assembly

Replace Fluid Pressure Sensor

Temperature RTD Sensor

Sensors

Remove Displacement Pump

Pump Assembly

Remove Pump Assembly

Remove Air Motor

Solvent Pump

Service and Repair

Fluid Heaters

Replace

Simplified Electrical Schematic, XM Sprayer with Alternator

Electrical Schematics

Electrical Schematics 313289S

Simplified Pneumatic Schematic, XM Sprayer with Alternator

313289S

Detailed Electrical Schematic, XM Sprayer with Alternator

Blue Green

Detailed Electrical Schematic, XM Sprayer with Alternator

XM Plural Component Sprayer with Wall Power

Simplified Electrical Schematic, XM Sprayer with Wall Power

Simplified Pneumatic Schematic, XM Sprayer with Wall Power

Manual

With Wall Power

Detailed Electrical Schematic, XM Sprayer with Wall Power

Box

Wiring Schematics

Fluid

Heaters

Hopper Heaters

Junction Box Wiring Schematics 313289S

XM Plural-Component Sprayers

Parts

XM1, XM2

XM3, XM4

XM7, XM8 Models

XMB and XME

XM5, XM6

113 114 120 121 122 135 137 115

Common Parts

Fluid Control Assembly Parts

Part Description Qty

See Air Controls Module Parts,

XM1 and XM2 Models

Parts Varying by Model

XM1 and XM2 Models

XM Plural-Component Sprayer Models Part Description

XM3 and XM4 Models

XM3 and XM4 Models

XM5 and XM6 Models

Adapter

XM7 and XM8 Models

XM7 and XM8 Models

Control Box 255771 Parts

Air Power and Electric Power Versions

Part Description

Label

MODULE, USB

Base

Alternator Assembly

Control Box Power Supply Options

Wall Power Supply Assembly Cable Connections

Wall Power Supply Assembly

Adapter

Air Controls Module 255761 Parts

Regulator

Coupling

Junction Box 256540 Parts

Switch 25A

Circuit Breaker 25A

Circuit Breaker 10A

SENSOR, RTD

Fluid Control Assembly Parts

CAP Plug

Air Inlet Manifold 255762 Parts

Swivel

Turbine

Alternator Module 255728 Parts

Repair and Spare Parts Reference

Part Description Qty Part of Assembly

Accessories and Kits

Desiccant Dryer Kit

Electric Heated Hose Power Supply Kit

Shutoff/Check Valve Kit

Caster Kit

System Dimensions without Hoppers

Dimensions

Two 20-Gallon Hoppers Rear Mounted

System Dimensions with Hoppers

Two 20-Gallon Hoppers Side Mounted

Two 7-Gallon Hoppers

One 20-Gallon Hopper and One 7-Gallon Hopper

PTFE, Uhmwpe

Technical Data

Graco Information

Graco Standard Warranty

![]()

![]() , and press

, and press ![]() again as necessary. These alarms prevent excessive pump speeds that can dam- age pump packings.

again as necessary. These alarms prevent excessive pump speeds that can dam- age pump packings.![]() .

.