|

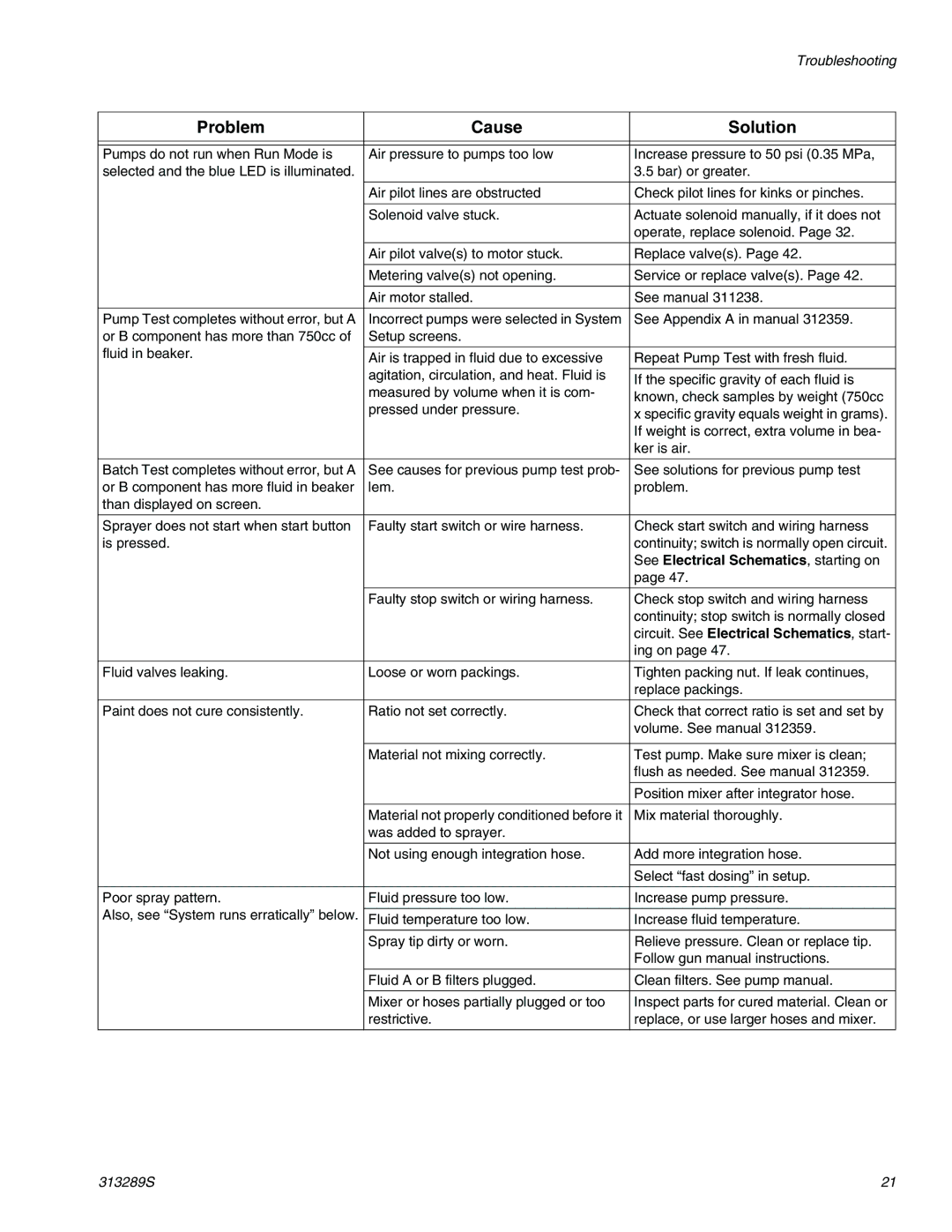

| Troubleshooting | |

|

|

| |

Problem | Cause | Solution | |

|

|

| |

|

|

| |

Pumps do not run when Run Mode is | Air pressure to pumps too low | Increase pressure to 50 psi (0.35 MPa, | |

selected and the blue LED is illuminated. |

| 3.5 bar) or greater. | |

|

|

| |

| Air pilot lines are obstructed | Check pilot lines for kinks or pinches. | |

|

|

| |

| Solenoid valve stuck. | Actuate solenoid manually, if it does not | |

|

| operate, replace solenoid. Page 32. | |

|

|

| |

| Air pilot valve(s) to motor stuck. | Replace valve(s). Page 42. | |

|

|

| |

| Metering valve(s) not opening. | Service or replace valve(s). Page 42. | |

|

|

| |

| Air motor stalled. | See manual 311238. | |

|

|

| |

Pump Test completes without error, but A | Incorrect pumps were selected in System | See Appendix A in manual 312359. | |

or B component has more than 750cc of | Setup screens. |

| |

fluid in beaker. |

|

| |

Air is trapped in fluid due to excessive | Repeat Pump Test with fresh fluid. | ||

| |||

| agitation, circulation, and heat. Fluid is |

| |

| If the specific gravity of each fluid is | ||

| measured by volume when it is com- | ||

| known, check samples by weight (750cc | ||

| pressed under pressure. | ||

| x specific gravity equals weight in grams). | ||

|

| ||

|

| If weight is correct, extra volume in bea- | |

|

| ker is air. | |

|

|

| |

Batch Test completes without error, but A | See causes for previous pump test prob- | See solutions for previous pump test | |

or B component has more fluid in beaker | lem. | problem. | |

than displayed on screen. |

|

| |

|

|

| |

Sprayer does not start when start button | Faulty start switch or wire harness. | Check start switch and wiring harness | |

is pressed. |

| continuity; switch is normally open circuit. | |

|

| See Electrical Schematics, starting on | |

|

| page 47. | |

|

|

| |

| Faulty stop switch or wiring harness. | Check stop switch and wiring harness | |

|

| continuity; stop switch is normally closed | |

|

| circuit. See Electrical Schematics, start- | |

|

| ing on page 47. | |

|

|

| |

Fluid valves leaking. | Loose or worn packings. | Tighten packing nut. If leak continues, | |

|

| replace packings. | |

|

|

| |

Paint does not cure consistently. | Ratio not set correctly. | Check that correct ratio is set and set by | |

|

| volume. See manual 312359. | |

|

|

| |

| Material not mixing correctly. | Test pump. Make sure mixer is clean; | |

|

| flush as needed. See manual 312359. | |

|

|

| |

|

| Position mixer after integrator hose. | |

|

|

| |

| Material not properly conditioned before it | Mix material thoroughly. | |

| was added to sprayer. |

| |

|

|

| |

| Not using enough integration hose. | Add more integration hose. | |

|

|

| |

|

| Select “fast dosing” in setup. | |

|

|

| |

Poor spray pattern. | Fluid pressure too low. | Increase pump pressure. | |

Also, see “System runs erratically” below. |

|

| |

Fluid temperature too low. | Increase fluid temperature. | ||

|

|

| |

| Spray tip dirty or worn. | Relieve pressure. Clean or replace tip. | |

|

| Follow gun manual instructions. | |

|

|

| |

| Fluid A or B filters plugged. | Clean filters. See pump manual. | |

|

|

| |

| Mixer or hoses partially plugged or too | Inspect parts for cured material. Clean or | |

| restrictive. | replace, or use larger hoses and mixer. | |

|

|

|

313289S | 21 |