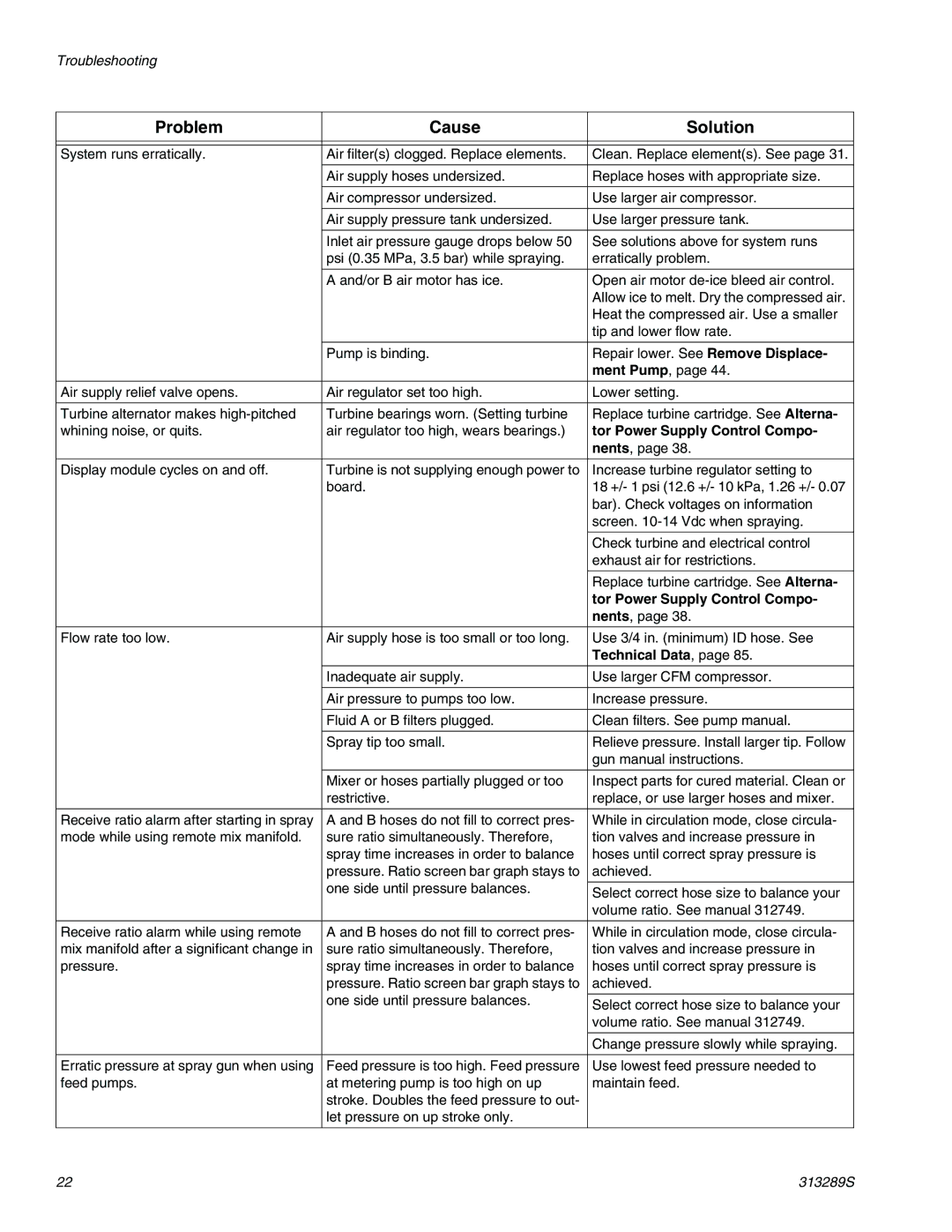

Troubleshooting

Problem | Cause | Solution |

|

|

|

|

|

|

System runs erratically. | Air filter(s) clogged. Replace elements. | Clean. Replace element(s). See page 31. |

|

|

|

| Air supply hoses undersized. | Replace hoses with appropriate size. |

|

|

|

| Air compressor undersized. | Use larger air compressor. |

|

|

|

| Air supply pressure tank undersized. | Use larger pressure tank. |

|

|

|

| Inlet air pressure gauge drops below 50 | See solutions above for system runs |

| psi (0.35 MPa, 3.5 bar) while spraying. | erratically problem. |

|

|

|

| A and/or B air motor has ice. | Open air motor |

|

| Allow ice to melt. Dry the compressed air. |

|

| Heat the compressed air. Use a smaller |

|

| tip and lower flow rate. |

|

|

|

| Pump is binding. | Repair lower. See Remove Displace- |

|

| ment Pump, page 44. |

|

|

|

Air supply relief valve opens. | Air regulator set too high. | Lower setting. |

|

|

|

Turbine alternator makes | Turbine bearings worn. (Setting turbine | Replace turbine cartridge. See Alterna- |

whining noise, or quits. | air regulator too high, wears bearings.) | tor Power Supply Control Compo- |

|

| nents, page 38. |

|

|

|

Display module cycles on and off. | Turbine is not supplying enough power to | Increase turbine regulator setting to |

| board. | 18 +/- 1 psi (12.6 +/- 10 kPa, 1.26 +/- 0.07 |

|

| bar). Check voltages on information |

|

| screen. |

|

|

|

|

| Check turbine and electrical control |

|

| exhaust air for restrictions. |

|

|

|

|

| Replace turbine cartridge. See Alterna- |

|

| tor Power Supply Control Compo- |

|

| nents, page 38. |

|

|

|

Flow rate too low. | Air supply hose is too small or too long. | Use 3/4 in. (minimum) ID hose. See |

|

| Technical Data, page 85. |

|

|

|

| Inadequate air supply. | Use larger CFM compressor. |

|

|

|

| Air pressure to pumps too low. | Increase pressure. |

|

|

|

| Fluid A or B filters plugged. | Clean filters. See pump manual. |

|

|

|

| Spray tip too small. | Relieve pressure. Install larger tip. Follow |

|

| gun manual instructions. |

|

|

|

| Mixer or hoses partially plugged or too | Inspect parts for cured material. Clean or |

| restrictive. | replace, or use larger hoses and mixer. |

|

|

|

Receive ratio alarm after starting in spray | A and B hoses do not fill to correct pres- | While in circulation mode, close circula- |

mode while using remote mix manifold. | sure ratio simultaneously. Therefore, | tion valves and increase pressure in |

| spray time increases in order to balance | hoses until correct spray pressure is |

| pressure. Ratio screen bar graph stays to | achieved. |

| one side until pressure balances. |

|

| Select correct hose size to balance your | |

|

| |

|

| volume ratio. See manual 312749. |

|

|

|

Receive ratio alarm while using remote | A and B hoses do not fill to correct pres- | While in circulation mode, close circula- |

mix manifold after a significant change in | sure ratio simultaneously. Therefore, | tion valves and increase pressure in |

pressure. | spray time increases in order to balance | hoses until correct spray pressure is |

| pressure. Ratio screen bar graph stays to | achieved. |

| one side until pressure balances. |

|

| Select correct hose size to balance your | |

|

| |

|

| volume ratio. See manual 312749. |

|

|

|

|

| Change pressure slowly while spraying. |

|

|

|

Erratic pressure at spray gun when using | Feed pressure is too high. Feed pressure | Use lowest feed pressure needed to |

feed pumps. | at metering pump is too high on up | maintain feed. |

| stroke. Doubles the feed pressure to out- |

|

| let pressure on up stroke only. |

|

|

|

|

22 | 313289S |