|

|

|

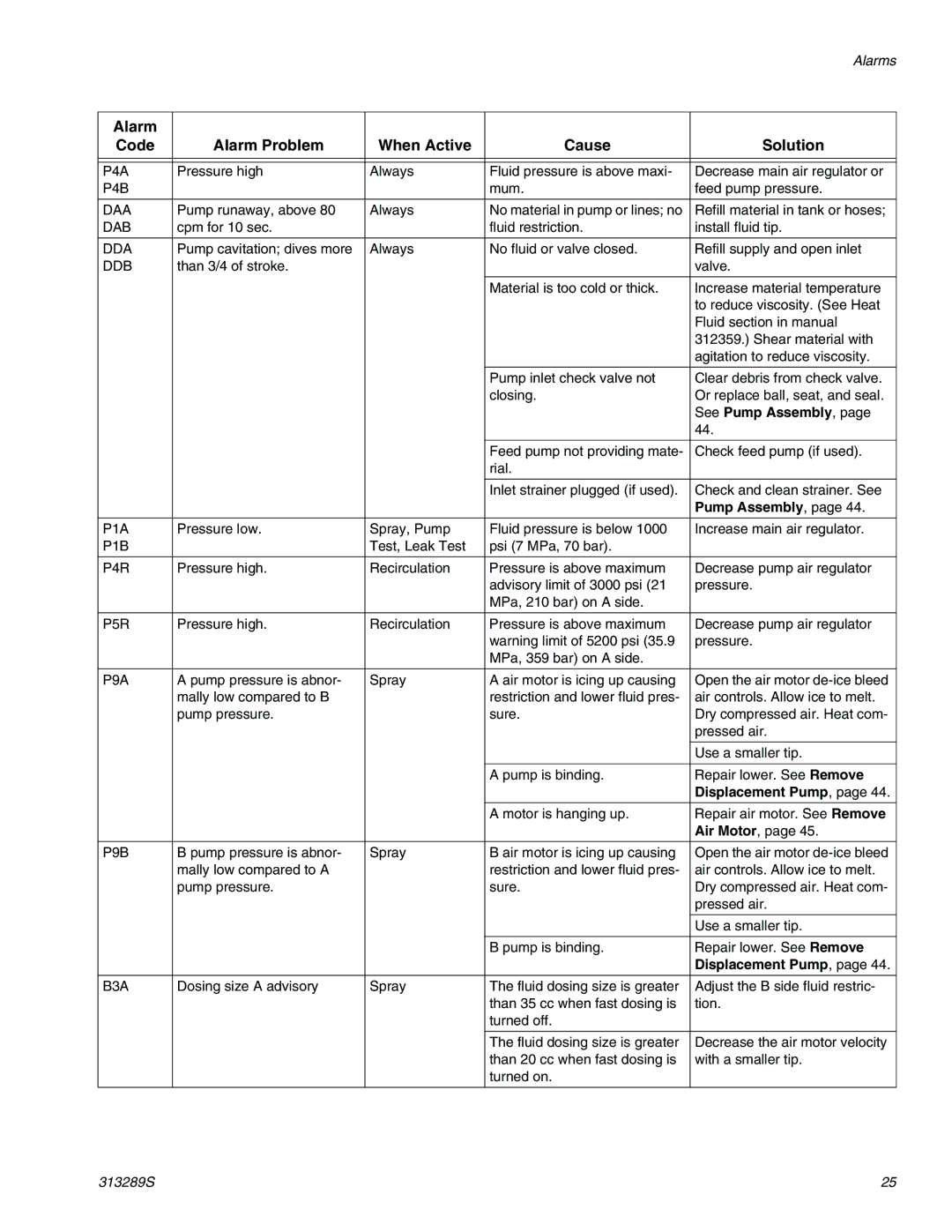

| Alarms |

|

|

|

|

|

Alarm |

|

|

|

|

Code | Alarm Problem | When Active | Cause | Solution |

|

|

|

|

|

|

|

|

|

|

P4A | Pressure high | Always | Fluid pressure is above maxi- | Decrease main air regulator or |

P4B |

|

| mum. | feed pump pressure. |

|

|

|

|

|

DAA | Pump runaway, above 80 | Always | No material in pump or lines; no | Refill material in tank or hoses; |

DAB | cpm for 10 sec. |

| fluid restriction. | install fluid tip. |

|

|

|

|

|

DDA | Pump cavitation; dives more | Always | No fluid or valve closed. | Refill supply and open inlet |

DDB | than 3/4 of stroke. |

|

| valve. |

|

|

|

|

|

|

|

| Material is too cold or thick. | Increase material temperature |

|

|

|

| to reduce viscosity. (See Heat |

|

|

|

| Fluid section in manual |

|

|

|

| 312359.) Shear material with |

|

|

|

| agitation to reduce viscosity. |

|

|

|

|

|

|

|

| Pump inlet check valve not | Clear debris from check valve. |

|

|

| closing. | Or replace ball, seat, and seal. |

|

|

|

| See Pump Assembly, page |

|

|

|

| 44. |

|

|

|

|

|

|

|

| Feed pump not providing mate- | Check feed pump (if used). |

|

|

| rial. |

|

|

|

|

|

|

|

|

| Inlet strainer plugged (if used). | Check and clean strainer. See |

|

|

|

| Pump Assembly, page 44. |

|

|

|

|

|

P1A | Pressure low. | Spray, Pump | Fluid pressure is below 1000 | Increase main air regulator. |

P1B |

| Test, Leak Test | psi (7 MPa, 70 bar). |

|

|

|

|

|

|

P4R | Pressure high. | Recirculation | Pressure is above maximum | Decrease pump air regulator |

|

|

| advisory limit of 3000 psi (21 | pressure. |

|

|

| MPa, 210 bar) on A side. |

|

|

|

|

|

|

P5R | Pressure high. | Recirculation | Pressure is above maximum | Decrease pump air regulator |

|

|

| warning limit of 5200 psi (35.9 | pressure. |

|

|

| MPa, 359 bar) on A side. |

|

|

|

|

|

|

P9A | A pump pressure is abnor- | Spray | A air motor is icing up causing | Open the air motor |

| mally low compared to B |

| restriction and lower fluid pres- | air controls. Allow ice to melt. |

| pump pressure. |

| sure. | Dry compressed air. Heat com- |

|

|

|

| pressed air. |

|

|

|

|

|

|

|

|

| Use a smaller tip. |

|

|

|

|

|

|

|

| A pump is binding. | Repair lower. See Remove |

|

|

|

| Displacement Pump, page 44. |

|

|

|

|

|

|

|

| A motor is hanging up. | Repair air motor. See Remove |

|

|

|

| Air Motor, page 45. |

|

|

|

|

|

P9B | B pump pressure is abnor- | Spray | B air motor is icing up causing | Open the air motor |

| mally low compared to A |

| restriction and lower fluid pres- | air controls. Allow ice to melt. |

| pump pressure. |

| sure. | Dry compressed air. Heat com- |

|

|

|

| pressed air. |

|

|

|

|

|

|

|

|

| Use a smaller tip. |

|

|

|

|

|

|

|

| B pump is binding. | Repair lower. See Remove |

|

|

|

| Displacement Pump, page 44. |

|

|

|

|

|

B3A | Dosing size A advisory | Spray | The fluid dosing size is greater | Adjust the B side fluid restric- |

|

|

| than 35 cc when fast dosing is | tion. |

|

|

| turned off. |

|

|

|

|

|

|

|

|

| The fluid dosing size is greater | Decrease the air motor velocity |

|

|

| than 20 cc when fast dosing is | with a smaller tip. |

|

|

| turned on. |

|

|

|

|

|

|

313289S | 25 |