Alarms

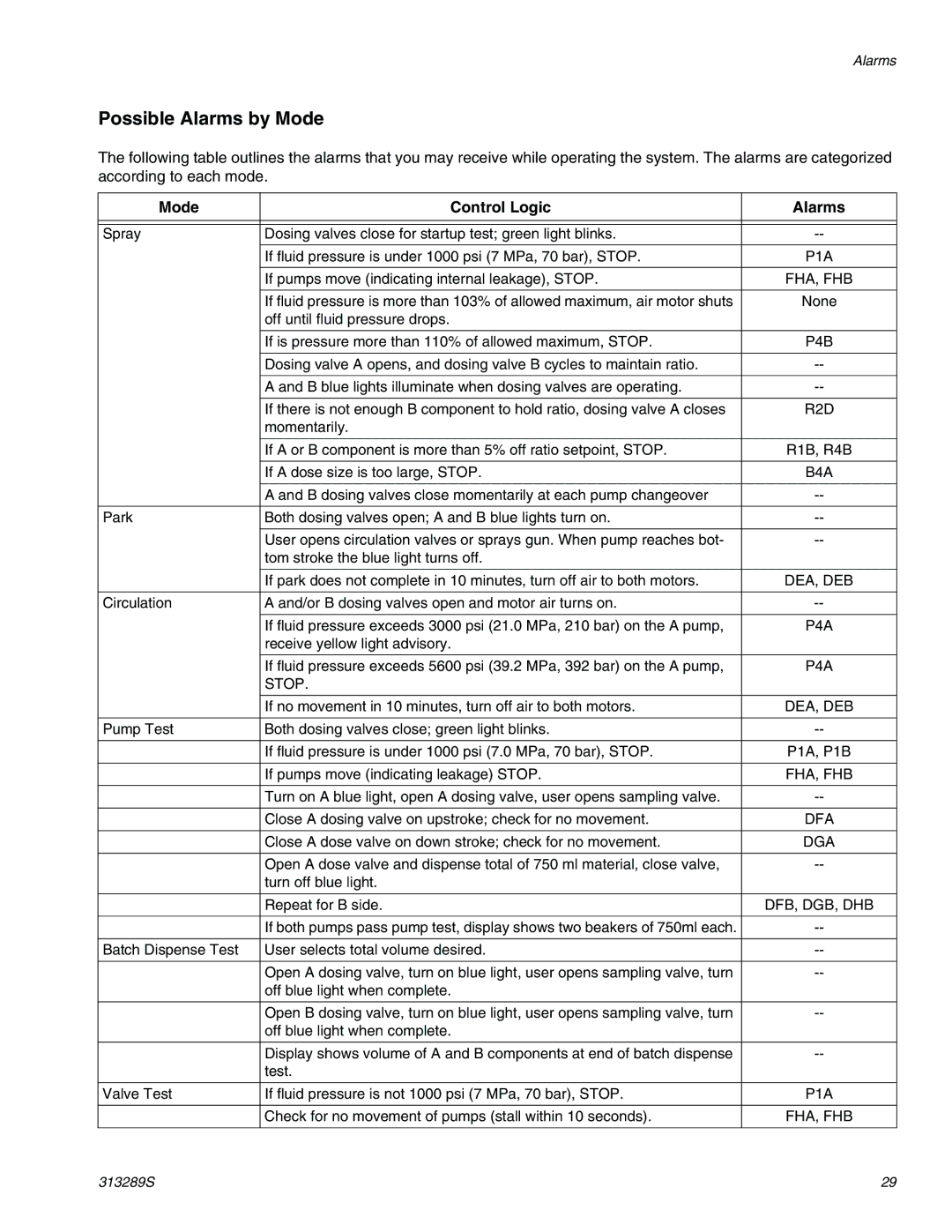

Possible Alarms by Mode

The following table outlines the alarms that you may receive while operating the system. The alarms are categorized according to each mode.

Mode | Control Logic | Alarms |

|

|

|

|

|

|

Spray | Dosing valves close for startup test; green light blinks. | |

|

|

|

| If fluid pressure is under 1000 psi (7 MPa, 70 bar), STOP. | P1A |

|

|

|

| If pumps move (indicating internal leakage), STOP. | FHA, FHB |

|

|

|

| If fluid pressure is more than 103% of allowed maximum, air motor shuts | None |

| off until fluid pressure drops. |

|

|

|

|

| If is pressure more than 110% of allowed maximum, STOP. | P4B |

|

|

|

| Dosing valve A opens, and dosing valve B cycles to maintain ratio. | |

|

|

|

| A and B blue lights illuminate when dosing valves are operating. | |

|

|

|

| If there is not enough B component to hold ratio, dosing valve A closes | R2D |

| momentarily. |

|

|

|

|

| If A or B component is more than 5% off ratio setpoint, STOP. | R1B, R4B |

|

|

|

| If A dose size is too large, STOP. | B4A |

|

|

|

| A and B dosing valves close momentarily at each pump changeover | |

|

|

|

Park | Both dosing valves open; A and B blue lights turn on. | |

|

|

|

| User opens circulation valves or sprays gun. When pump reaches bot- | |

| tom stroke the blue light turns off. |

|

|

|

|

| If park does not complete in 10 minutes, turn off air to both motors. | DEA, DEB |

|

|

|

Circulation | A and/or B dosing valves open and motor air turns on. | |

|

|

|

| If fluid pressure exceeds 3000 psi (21.0 MPa, 210 bar) on the A pump, | P4A |

| receive yellow light advisory. |

|

|

|

|

| If fluid pressure exceeds 5600 psi (39.2 MPa, 392 bar) on the A pump, | P4A |

| STOP. |

|

|

|

|

| If no movement in 10 minutes, turn off air to both motors. | DEA, DEB |

|

|

|

Pump Test | Both dosing valves close; green light blinks. | |

|

|

|

| If fluid pressure is under 1000 psi (7.0 MPa, 70 bar), STOP. | P1A, P1B |

|

|

|

| If pumps move (indicating leakage) STOP. | FHA, FHB |

|

|

|

| Turn on A blue light, open A dosing valve, user opens sampling valve. | |

|

|

|

| Close A dosing valve on upstroke; check for no movement. | DFA |

|

|

|

| Close A dose valve on down stroke; check for no movement. | DGA |

|

|

|

| Open A dose valve and dispense total of 750 ml material, close valve, | |

| turn off blue light. |

|

|

|

|

| Repeat for B side. | DFB, DGB, DHB |

|

|

|

| If both pumps pass pump test, display shows two beakers of 750ml each. | |

|

|

|

Batch Dispense Test | User selects total volume desired. | |

|

|

|

| Open A dosing valve, turn on blue light, user opens sampling valve, turn | |

| off blue light when complete. |

|

|

|

|

| Open B dosing valve, turn on blue light, user opens sampling valve, turn | |

| off blue light when complete. |

|

|

|

|

| Display shows volume of A and B components at end of batch dispense | |

| test. |

|

|

|

|

Valve Test | If fluid pressure is not 1000 psi (7 MPa, 70 bar), STOP. | P1A |

|

|

|

| Check for no movement of pumps (stall within 10 seconds). | FHA, FHB |

|

|

|

313289S | 29 |