4-Jaw Chuck

Always use a low spindle speed when machining

The 8"

Mounting Workpiece |

|

Tools Needed | Qty |

1 | |

Plywood 3⁄4" (Bedway) | 1 |

To mount a workpiece onto the 4-jaw chuck:

1.DISCONNECT LATHE FROM POWER!

2.Lay a piece of plywood on the bedway under the chuck to protect it.

3.Use the chuck key to open each jaw so the workpiece will lay flat against the chuck face or jaw steps.

4.With assistance or a supporting device, mount the workpiece centered on the chuck, then turn each jaw until it makes contact with the workpiece.

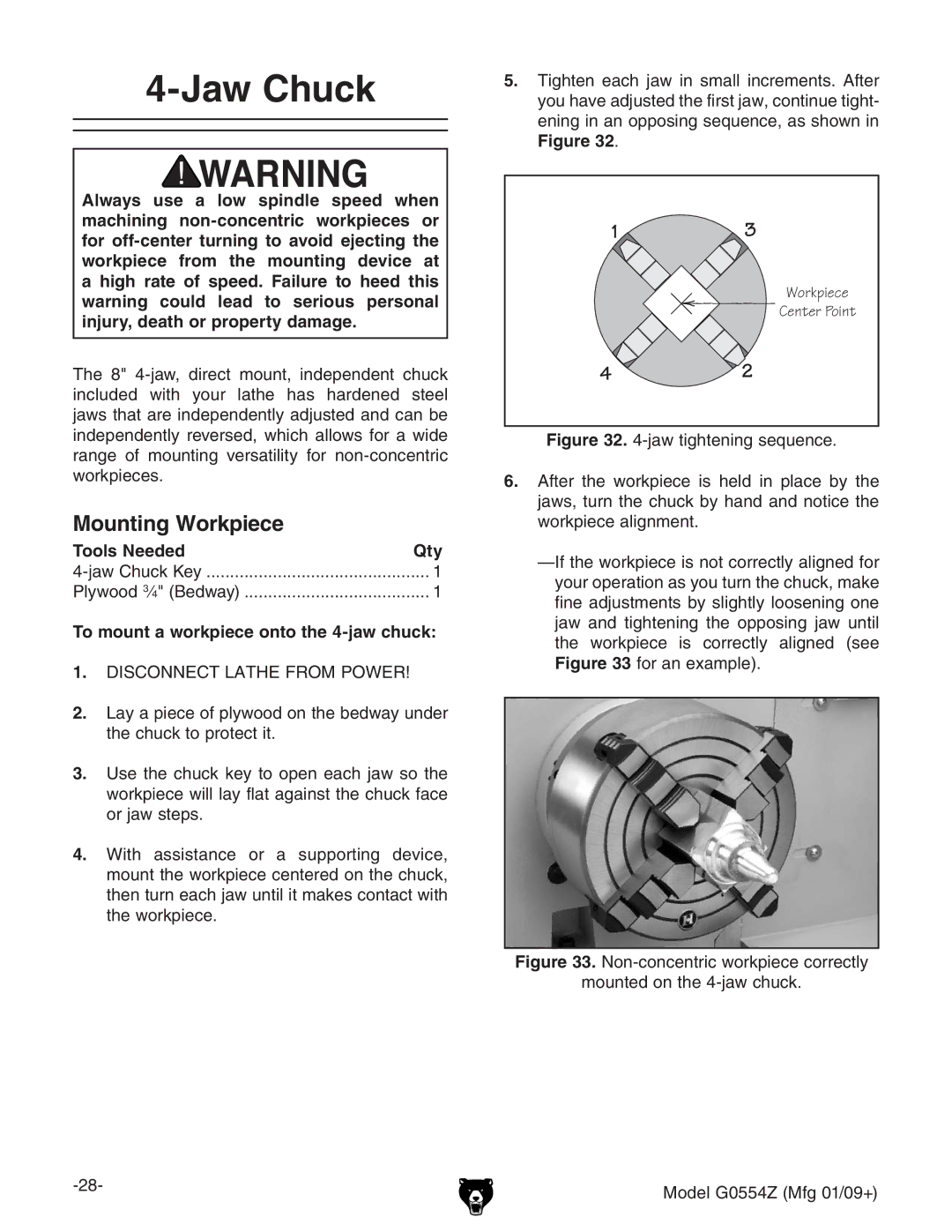

5.Tighten each jaw in small increments. After you have adjusted the first jaw, continue tight- ening in an opposing sequence, as shown in

Figure 32.

13

Workpiece

![]()

![]()

![]() Center Point

Center Point

42