Tensioning/

Replacing V-Belts

NOTICE

After the first 16 hours of use, the

To ensure efficient transfer of power to the spin- dle, make sure the

If a

Tools Needed | Qty |

Phillips Screwdriver #2 | 1 |

Hex Wrench 5mm | 1 |

Wrench or Deep Socket 24mm | 1 |

Tensioning V-Belts

1.DISCONNECT LATHE FROM POWER!

2.Open the left side door, then remove the left and rear lower access panels.

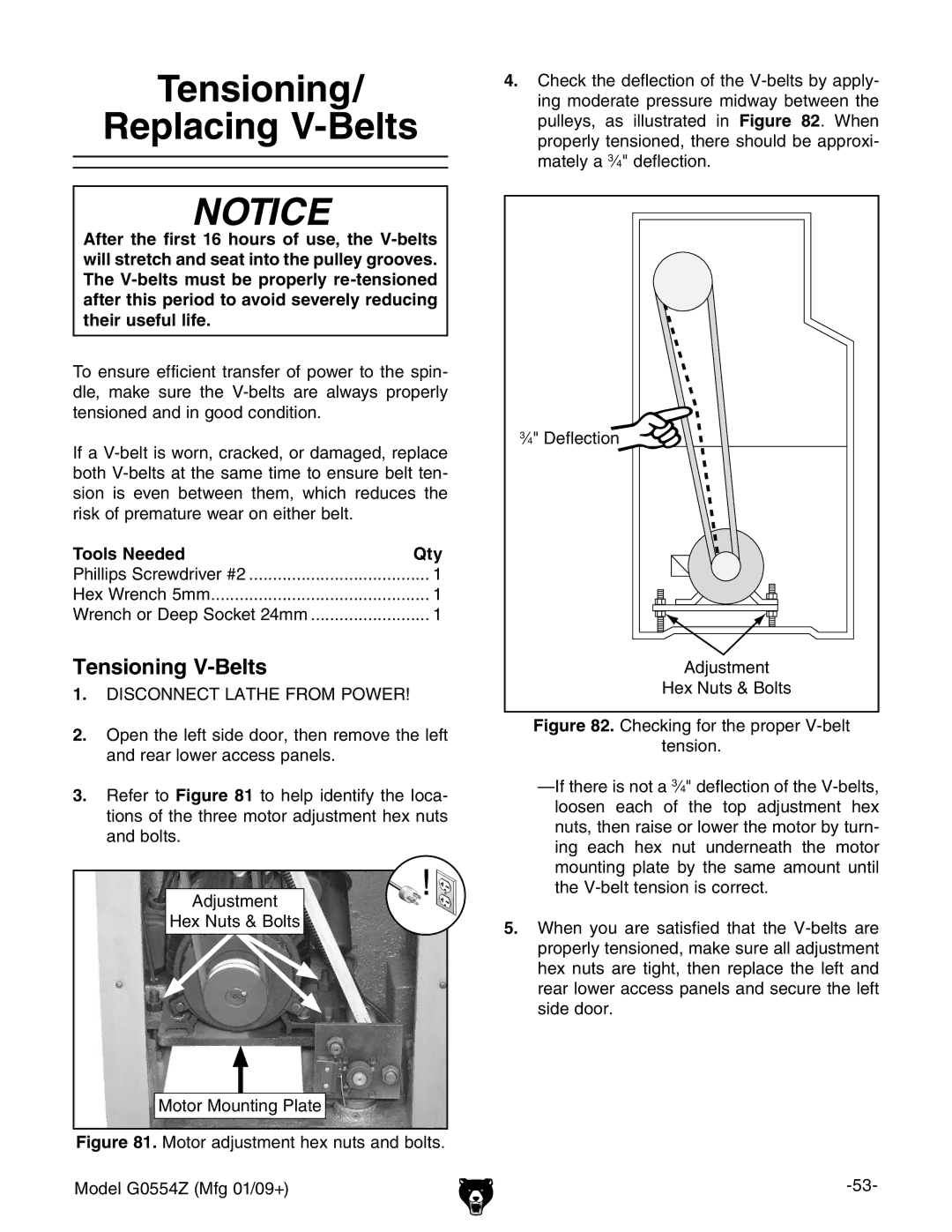

3.Refer to Figure 81 to help identify the loca- tions of the three motor adjustment hex nuts and bolts.

Adjustment |

Hex Nuts & Bolts |

Motor Mounting Plate |