2.Determine the final diameter, in inches, for the cut you intend to make.

Note: For this step, you will need to aver- age out the diameters or work with the finish diameter.

3.Use the following formula to determine the correct spindle speed (RPM) for your opera- tion:

*Recommended Spindle Cutting Speed (FPM) x 12

= Speed Dia. of Cut (in inches) x 3.14 (RPM)

*Double if using carbide cutting tool

Example A:

You will finish cut a 1⁄2" diameter piece of cast steel stock, using an HSS cutting tool.

Step 1:

150 (SFM from chart) x 4 = 600

Step 2:

600 / .5" (Diameter of workpiece) = 1200

Result:

The correct spindle speed is 1200 RPM.

Example B:

You will rough turn a 1" diameter piece of stainless steel, using a carbide cutting tool.

Step 1:

60 (SFM from chart) x 2 (for carbide tool) = 120

Step 2:

120 (Calculated SFM) x 4 = 480

Step 3:

480 / 1" (Diameter of workpiece) = 480

RPM

Result:

The correct spindle speed is 480 RPM.

Model G0554Z (Mfg 01/09+)

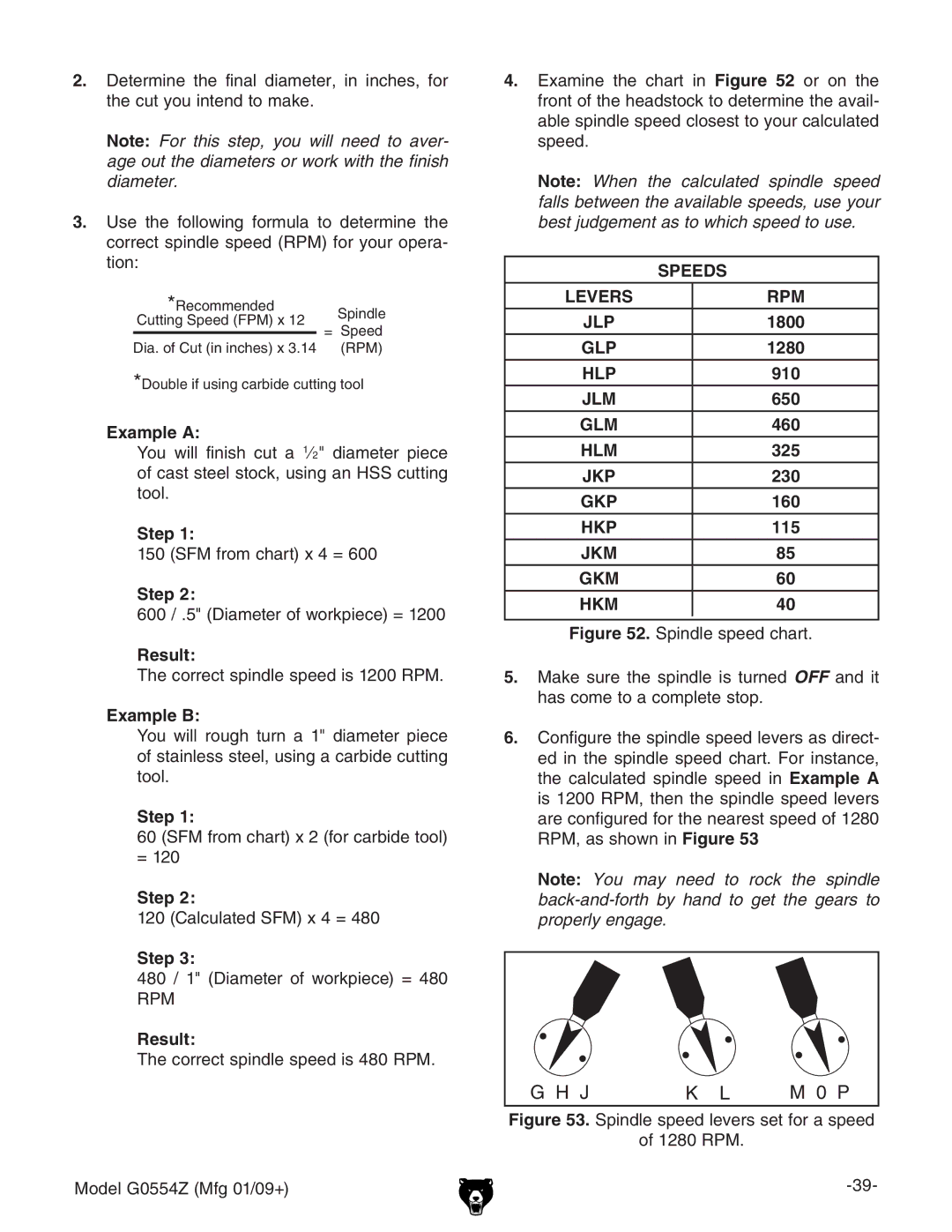

4.Examine the chart in Figure 52 or on the front of the headstock to determine the avail- able spindle speed closest to your calculated speed.

Note: When the calculated spindle speed falls between the available speeds, use your best judgement as to which speed to use.

| SPEEDS | |

LEVERS |

| RPM |

|

|

|

JLP |

| 1800 |

|

|

|

GLP |

| 1280 |

|

|

|

HLP |

| 910 |

|

|

|

JLM |

| 650 |

|

|

|

GLM |

| 460 |

|

|

|

HLM |

| 325 |

|

|

|

JKP |

| 230 |

|

|

|

GKP |

| 160 |

|

|

|

HKP |

| 115 |

|

|

|

JKM |

| 85 |

|

|

|

GKM |

| 60 |

|

|

|

HKM |

| 40 |

|

|

|

Figure 52. Spindle speed chart.

5.Make sure the spindle is turned OFF and it has come to a complete stop.

6.Configure the spindle speed levers as direct- ed in the spindle speed chart. For instance, the calculated spindle speed in Example A is 1200 RPM, then the spindle speed levers are configured for the nearest speed of 1280 RPM, as shown in Figure 53

Note: You may need to rock the spindle

G H J | K L | M 0 P |