Shear Pin

Replacement

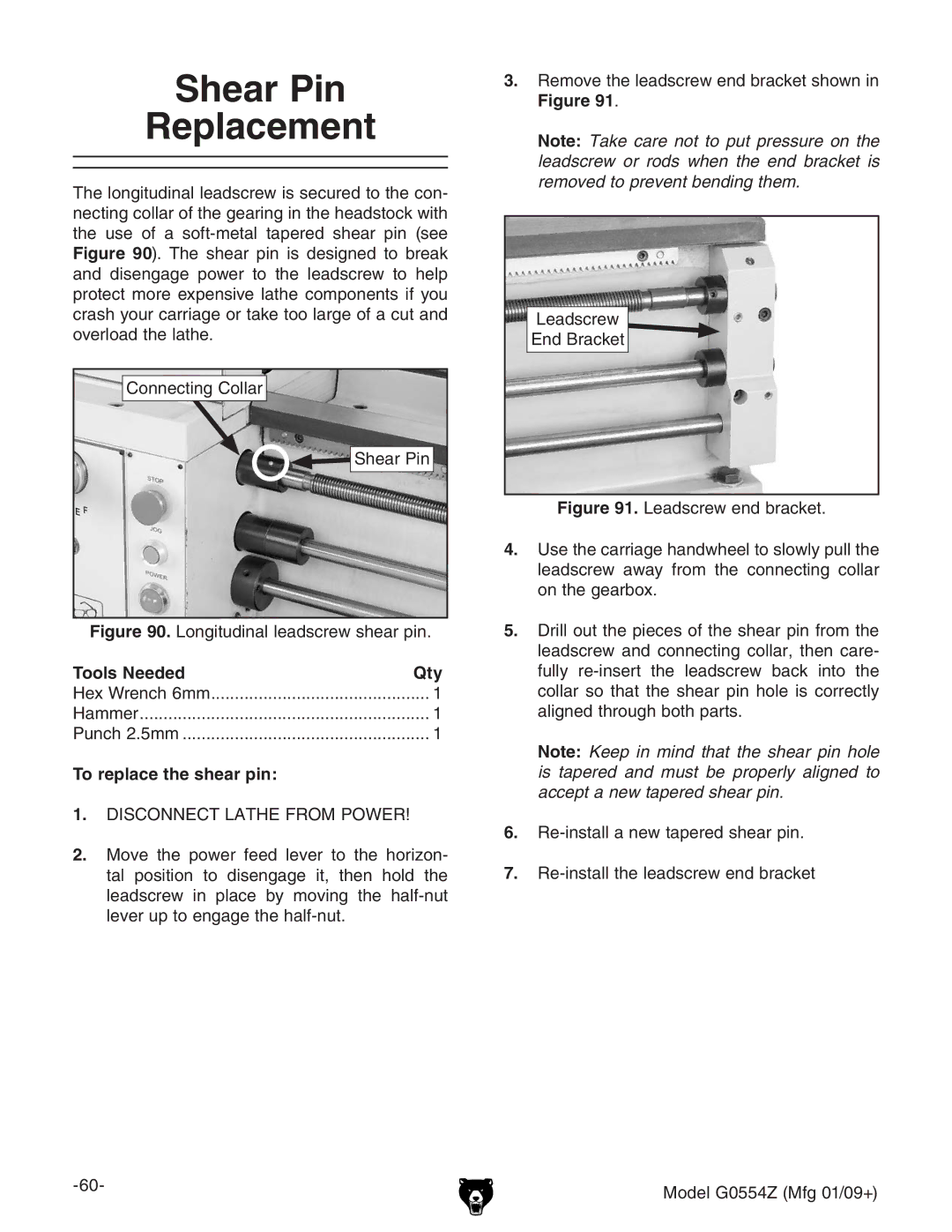

The longitudinal leadscrew is secured to the con- necting collar of the gearing in the headstock with the use of a

Connecting Collar

![]()

![]() Shear Pin

Shear Pin

Figure 90. Longitudinal leadscrew shear pin.

Tools Needed | Qty |

Hex Wrench 6mm | 1 |

Hammer | 1 |

Punch 2.5mm | 1 |

To replace the shear pin: |

|

1.DISCONNECT LATHE FROM POWER!

2.Move the power feed lever to the horizon- tal position to disengage it, then hold the leadscrew in place by moving the

3.Remove the leadscrew end bracket shown in

Figure 91.

Note: Take care not to put pressure on the leadscrew or rods when the end bracket is removed to prevent bending them.

Leadscrew

End Bracket

Figure 91. Leadscrew end bracket.

4.Use the carriage handwheel to slowly pull the leadscrew away from the connecting collar on the gearbox.

5.Drill out the pieces of the shear pin from the leadscrew and connecting collar, then care- fully re-insert the leadscrew back into the collar so that the shear pin hole is correctly aligned through both parts.

Note: Keep in mind that the shear pin hole is tapered and must be properly aligned to accept a new tapered shear pin.