6.Remove the three cap screws that secure the spindle nut.

7.If you are performing this procedure because the normal operating temperature of the spindle was too hot, proceed with Step 8.

If you are performing this procedure because of excessive spindle

8.To unload the bearing preload, insert the spindle lock key in a spindle indent to keep the spindle from rotating, the use the spanner wrench to loosen the spindle nut one full turn counterclockwise.

Note: You may have to tap on the outboard portion of the spindle as explained in Step 9 to help unload the spindle preload and break the spindle nut loose.

9.Place the wooden block over the outboard end of the spindle, and hit it soundly with the heavy dead blow hammer, as shown in

Figure 96.

Your goal is to slide the spindle forward just enough to introduce spindle

Figure 96. Introducing detectable spindle end-

play.

Model G0554Z (Mfg 01/09+)

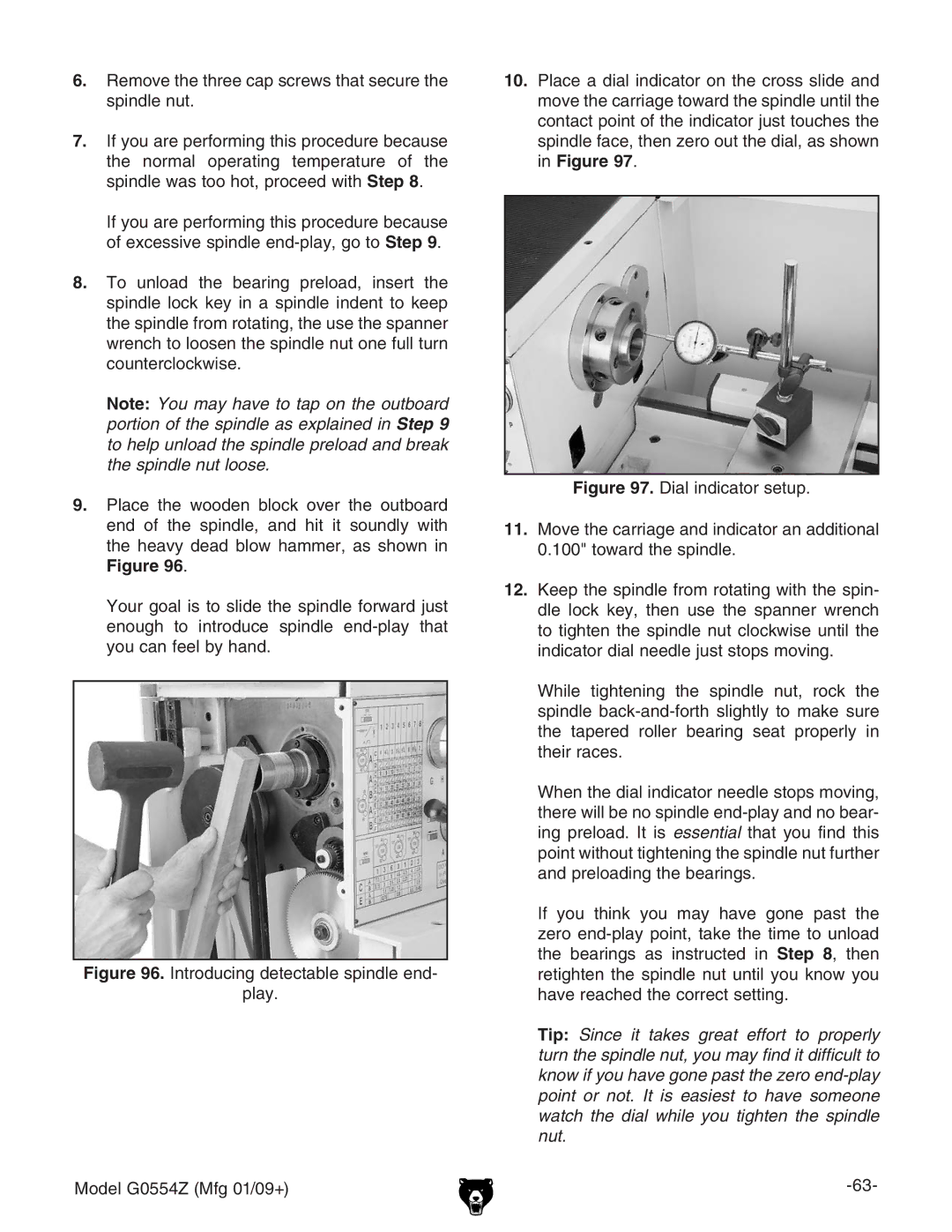

10.Place a dial indicator on the cross slide and move the carriage toward the spindle until the contact point of the indicator just touches the spindle face, then zero out the dial, as shown in Figure 97.

Figure 97. Dial indicator setup.

11.Move the carriage and indicator an additional 0.100" toward the spindle.

12.Keep the spindle from rotating with the spin- dle lock key, then use the spanner wrench to tighten the spindle nut clockwise until the indicator dial needle just stops moving.

While tightening the spindle nut, rock the spindle back-and-forth slightly to make sure the tapered roller bearing seat properly in their races.

When the dial indicator needle stops moving, there will be no spindle end-play and no bear- ing preload. It is essential that you find this point without tightening the spindle nut further and preloading the bearings.

If you think you may have gone past the zero end-play point, take the time to unload the bearings as instructed in Step 8, then retighten the spindle nut until you know you have reached the correct setting.

Tip: Since it takes great effort to properly turn the spindle nut, you may find it difficult to know if you have gone past the zero