Threading Controls

The purpose of this subsection is to orient you with the controls used when threading and how to use the threading dial.

If you are unfamiliar with threading on a lathe, we strongly recommend that you read books, review industry trade magazines, or get formal training before beginning any threading projects.

Power Feed Lever

The power feed lever must be in the disengaged (horizontal) position for threading operations or the

Power Feed Lever |

|

Horizontal & | |

Disengaged | Down & Engaged |

Figure 63. Carriage controls set up for

threading.

Half-Nut Lever

The

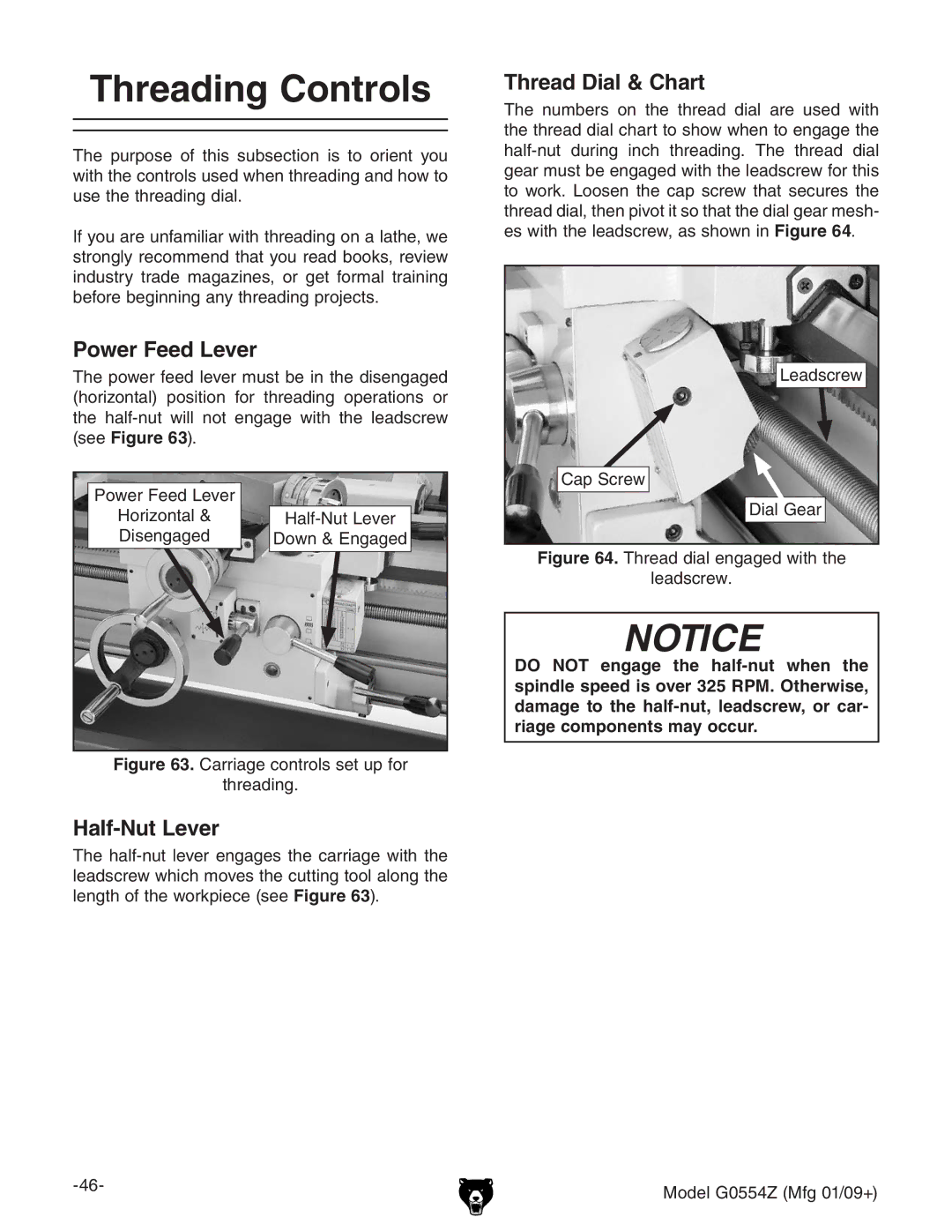

Thread Dial & Chart

The numbers on the thread dial are used with the thread dial chart to show when to engage the

Leadscrew

Cap Screw

Dial Gear

Figure 64. Thread dial engaged with the

leadscrew.

NOTICE

DO NOT engage the

Model G0554Z (Mfg 01/09+) | |

|