9.Use a caliper to measure both ends of the workpiece.

Move the tailstock toward |

the operator half the |

distance of the taper. |

Looking down from above. |

Figure 41. Adjust tailstock toward the operator.

—If the machined workpiece is thinner at the tailstock end, move the tailstock away from the operator 1⁄2 the distance of the amount of taper (see Figure 42).

Looking down from above. |

Move tailstock away from |

the operator half the |

distance of the taper. |

Figure 42. Adjust tailstock away from the

operator.

Drilling with

Tailstock

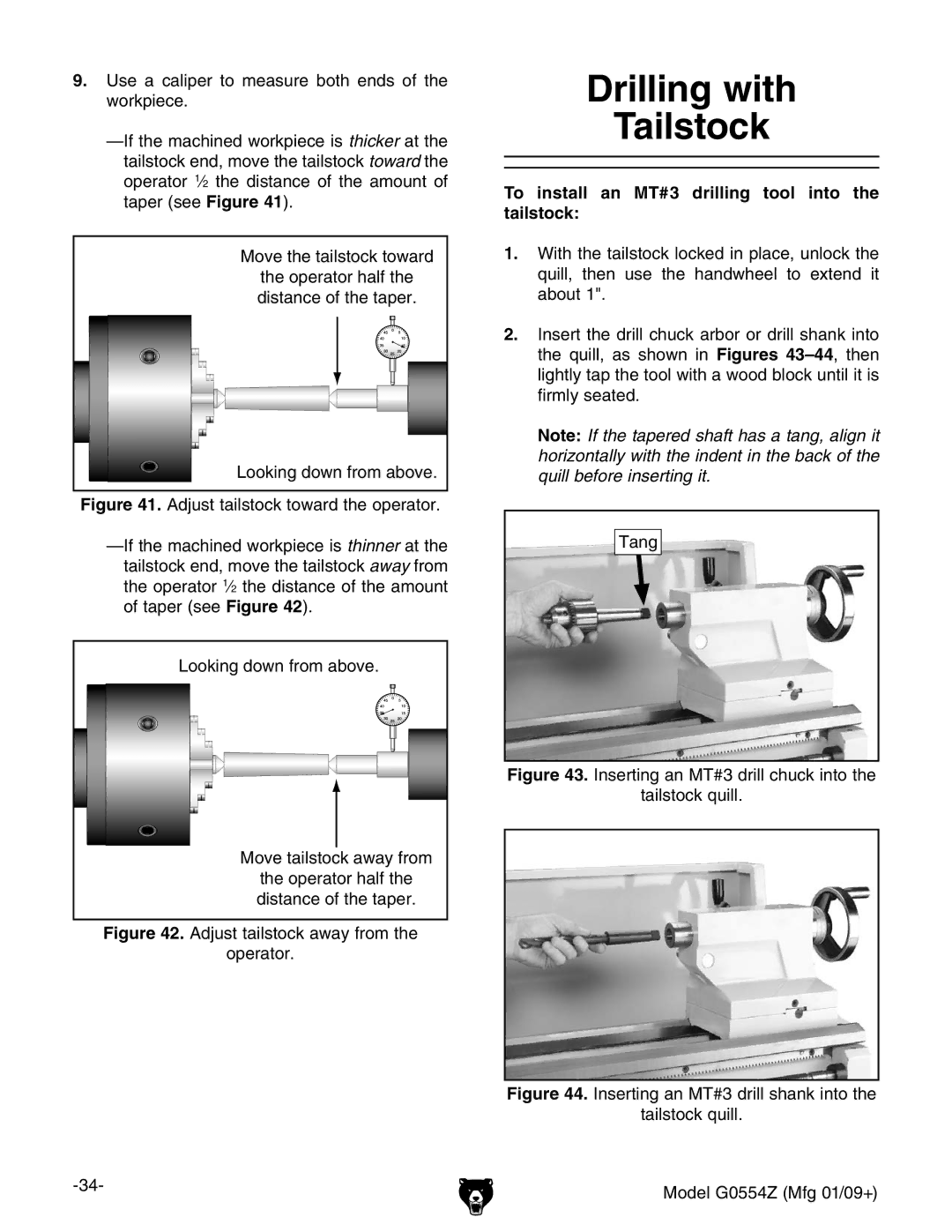

To install an MT#3 drilling tool into the tailstock:

1.With the tailstock locked in place, unlock the quill, then use the handwheel to extend it about 1".

2.Insert the drill chuck arbor or drill shank into the quill, as shown in Figures

Note: If the tapered shaft has a tang, align it horizontally with the indent in the back of the quill before inserting it.

Tang

Figure 43. Inserting an MT#3 drill chuck into the

tailstock quill.

Figure 44. Inserting an MT#3 drill shank into the

tailstock quill.

Model G0554Z (Mfg 01/09+) | |

|