Power Feed

Understanding the Feed Rate & Threading Charts

Power feed on the Model G0554Z uses the machine to move the tooling rather than manual rotation of the handwheels. When the feed rod is engaged, the carriage or cross slide moves. Threading operations use powered rotation of the longitudinal leadscrew with the

The feed rate that these components travels is set with the feed rate lever/knobs and the quick change gears, but it is also dependent upon the spindle speed.

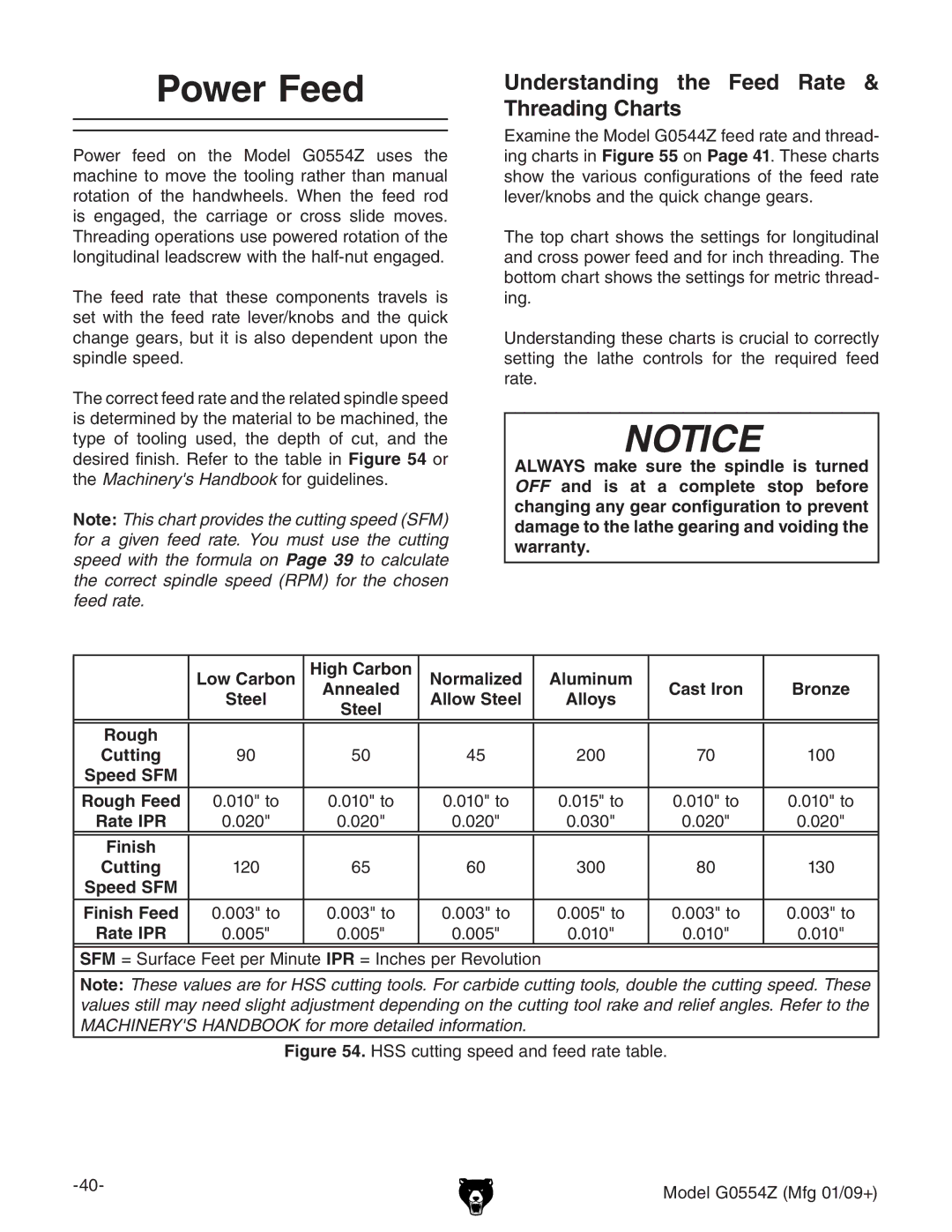

The correct feed rate and the related spindle speed is determined by the material to be machined, the type of tooling used, the depth of cut, and the desired finish. Refer to the table in Figure 54 or the Machinery's Handbook for guidelines.

Note: This chart provides the cutting speed (SFM) for a given feed rate. You must use the cutting speed with the formula on Page 39 to calculate the correct spindle speed (RPM) for the chosen feed rate.

Examine the Model G0544Z feed rate and thread- ing charts in Figure 55 on Page 41. These charts show the various configurations of the feed rate lever/knobs and the quick change gears.

The top chart shows the settings for longitudinal and cross power feed and for inch threading. The bottom chart shows the settings for metric thread- ing.

Understanding these charts is crucial to correctly setting the lathe controls for the required feed rate.

NOTICE

ALWAYS make sure the spindle is turned OFF and is at a complete stop before changing any gear configuration to prevent damage to the lathe gearing and voiding the warranty.

| Low Carbon | High Carbon | Normalized | Aluminum | Cast Iron | Bronze |

| Steel | Annealed | Allow Steel | Alloys | ||

| Steel |

|

| |||

|

|

|

|

|

| |

|

|

|

|

|

|

|

Rough |

|

|

|

|

|

|

Cutting | 90 | 50 | 45 | 200 | 70 | 100 |

Speed SFM |

|

|

|

|

|

|

Rough Feed | 0.010" to | 0.010" to | 0.010" to | 0.015" to | 0.010" to | 0.010" to |

Rate IPR | 0.020" | 0.020" | 0.020" | 0.030" | 0.020" | 0.020" |

|

|

|

|

|

|

|

Finish |

|

|

|

|

|

|

Cutting | 120 | 65 | 60 | 300 | 80 | 130 |

Speed SFM |

|

|

|

|

|

|

Finish Feed | 0.003" to | 0.003" to | 0.003" to | 0.005" to | 0.003" to | 0.003" to |

Rate IPR | 0.005" | 0.005" | 0.005" | 0.010" | 0.010" | 0.010" |

SFM = Surface Feet per Minute IPR = Inches per Revolution

Note: These values are for HSS cutting tools. For carbide cutting tools, double the cutting speed. These values still may need slight adjustment depending on the cutting tool rake and relief angles. Refer to the MACHINERY'S HANDBOOK for more detailed information.

Figure 54. HSS cutting speed and feed rate table.

Model G0554Z (Mfg 01/09+) | |

|