Faceplate

The 12" faceplate included with your lathe is used when machining

Use a minimum of three independent clamping devices to hold a

Loading Workpiece

1.DISCONNECT LATHE FROM POWER!

2.Lay a piece of plywood on the bedway under the faceplate to protect it.

Always use a low spindle speed when machining

Model G0554Z (Mfg 01/09+)

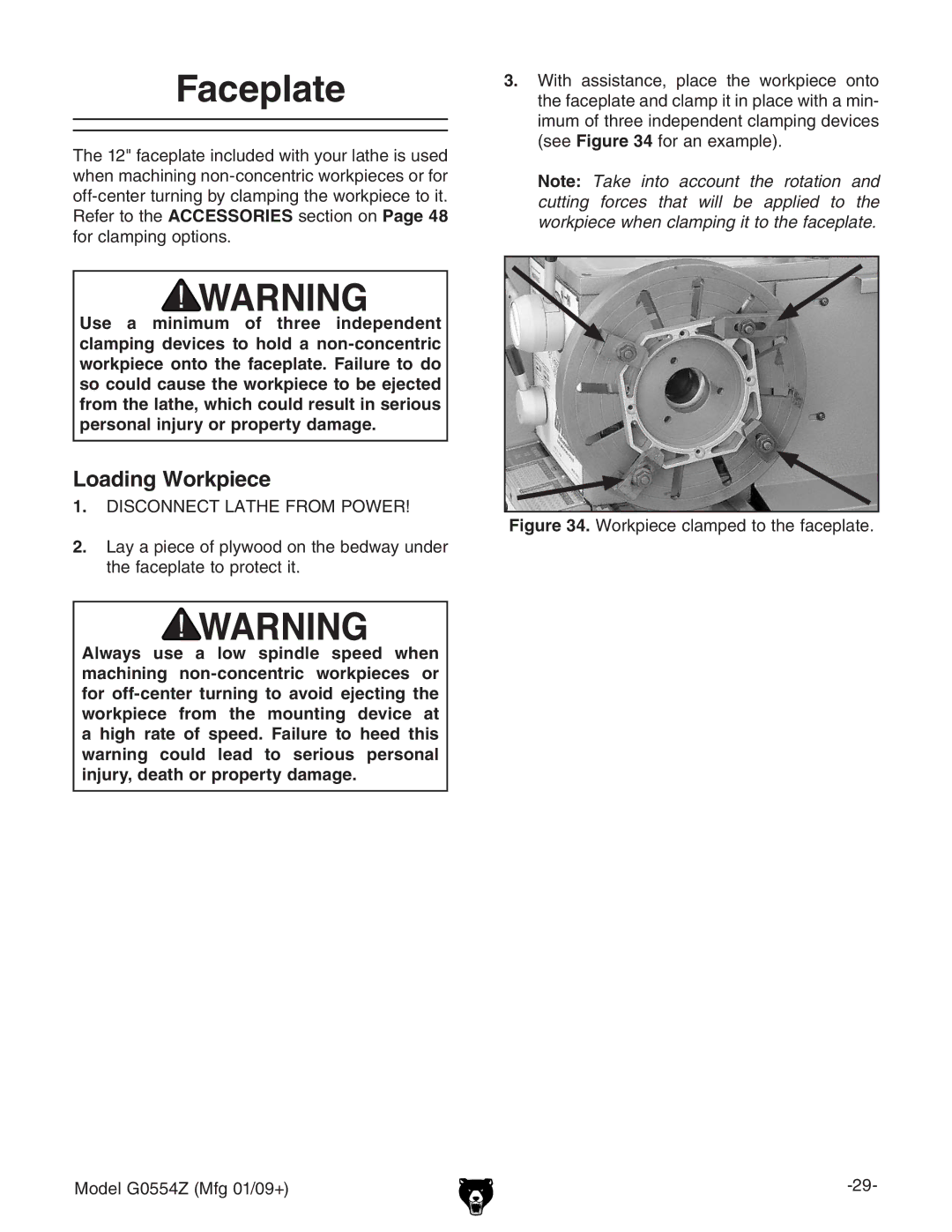

3.With assistance, place the workpiece onto the faceplate and clamp it in place with a min- imum of three independent clamping devices (see Figure 34 for an example).

Note: Take into account the rotation and cutting forces that will be applied to the workpiece when clamping it to the faceplate.