Cross Slide

Backlash Adjustment

Backlash is the amount of play in a leadscrew. It is felt when turning the handwheel in one direc- tion, then turning it in the other direction. The distance the handwheel moves without moving the leadscrew or the attached component is the backlash.

When adjusting the backlash, the goal is to remove excess backlash without making the cross slide bind, making it hard to move. Overtightening will cause excessive wear on the sliding surfaces and the leadscrew. Generally, a backlash of 0.003"– 0.006" is acceptable.

Tools Needed | Qty |

Hex Wrench 5mm. | ............................................. 1 |

To remove excess cross slide backlash:

1.DISCONNECT LATHE FROM POWER!

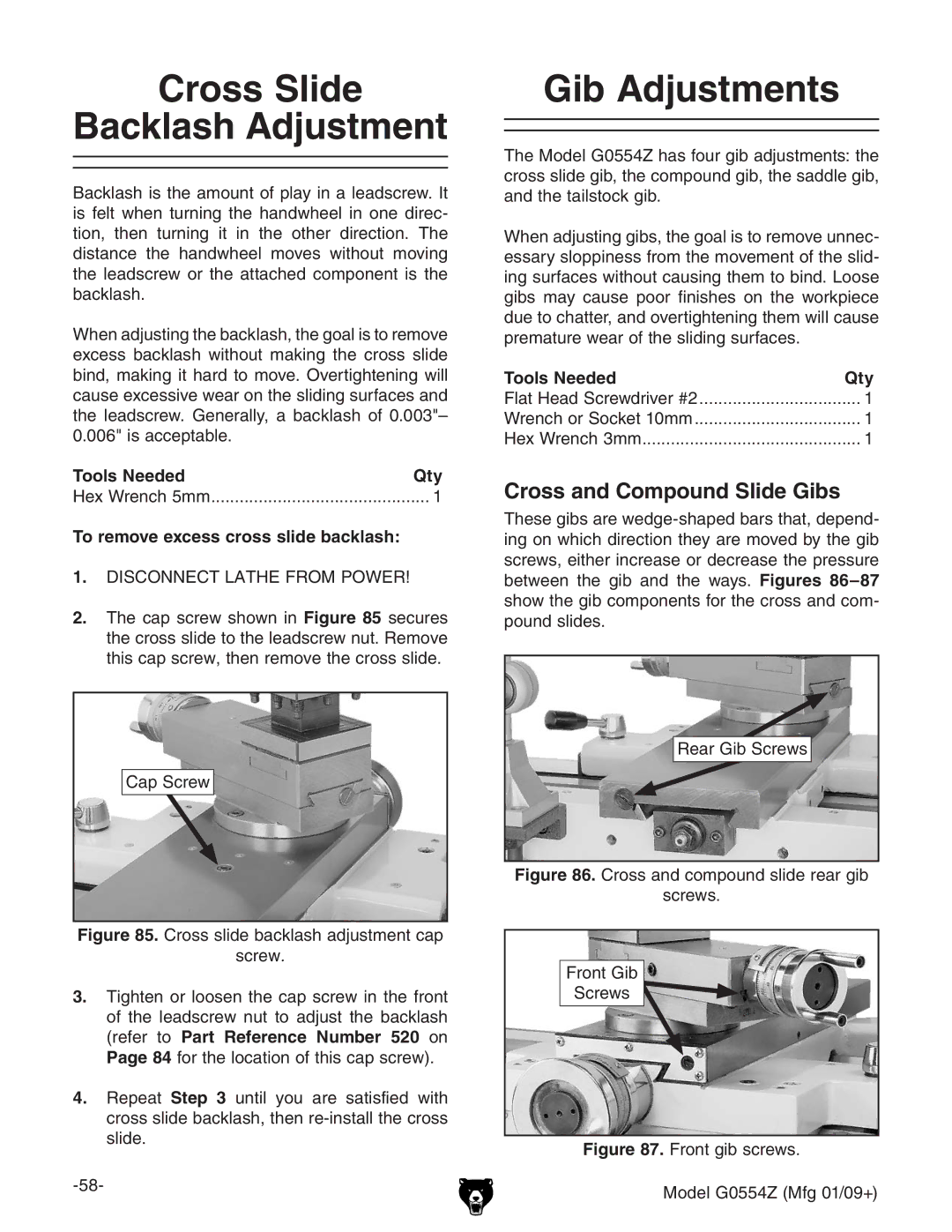

2.The cap screw shown in Figure 85 secures the cross slide to the leadscrew nut. Remove this cap screw, then remove the cross slide.

Cap Screw

Figure 85. Cross slide backlash adjustment cap

screw.

3.Tighten or loosen the cap screw in the front of the leadscrew nut to adjust the backlash (refer to Part Reference Number 520 on

Page 84 for the location of this cap screw).

4.Repeat Step 3 until you are satisfied with cross slide backlash, then re-install the cross slide.

Gib Adjustments

The Model G0554Z has four gib adjustments: the cross slide gib, the compound gib, the saddle gib, and the tailstock gib.

When adjusting gibs, the goal is to remove unnec- essary sloppiness from the movement of the slid- ing surfaces without causing them to bind. Loose gibs may cause poor finishes on the workpiece due to chatter, and overtightening them will cause premature wear of the sliding surfaces.

Tools Needed | Qty |

Flat Head Screwdriver #2 | .................................. 1 |

Wrench or Socket 10mm | 1 |

Hex Wrench 3mm | 1 |

Cross and Compound Slide Gibs

These gibs are

Rear Gib Screws

Figure 86. Cross and compound slide rear gib

screws.

Front Gib

Screws