U.Apron. Houses the carriage gearing and internal components.

V.Longitudinal Handwheel: Moves the car- riage from

W.Cross Slide Handwheel: Moves the cross slide toward and away from the work. The graduated dial is adjustable using the same method as the dial on the cross slide and is marked in increments of 0.001" or 0.02mm. The cross slide dial is a "direct read" dial, which means that the distance it indicates is the actual amount removed from the diam- eter of the workpiece, even though the cross slide moves only 1⁄2 that distance.

Note: Direct read means that the distance the handwheel dial indicates is what is removed from the diameter of the workpiece. The cross slide only moves 1⁄2 that distance.

X.Saddle: Rides on top of the bedways and supports the cross slide and apron.

Y.Cross Slide: Moves

Model G0554Z (Mfg 01/09+)

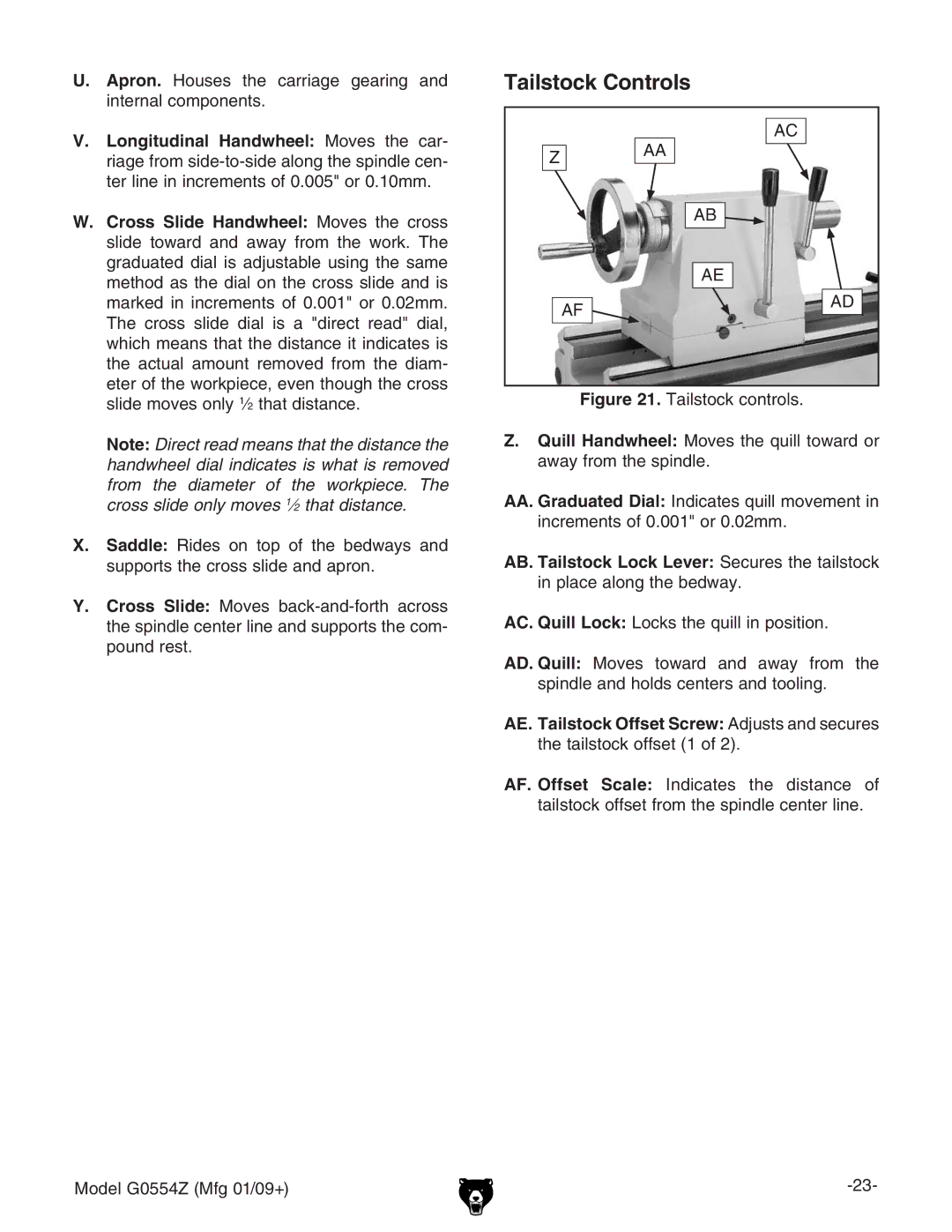

Tailstock Controls

AC

|

| AA | |

Z | |||

|

| ||

|

|

|

AB ![]()

| AE |

AF | AD |

|