If the machine doesn't have a built in dust port, use Figure 48 as a guide to determine which size of dust port to install on the machine.

Machine | average Dust Port Size | |

Table Saw | 4" | |

2" | ||

Jointer (6" and smaller) | 4" | |

Jointer | 5" | |

Thickness Planer (13" and smaller) | 4" | |

Thickness Planer | 6" | |

Shaper | 4" | |

Router (mounted to table) | 2" | |

Bandsaw | 4" | |

Lathe | 4" | |

Disc Sander (12" and smaller) | 2" | |

Disc Sander | 4" | |

Belt Sander (6" and smaller) | 2" | |

Belt Sander | 3" | |

Edge Sander (6" x 80" and smaller) | 4" | |

Edge Sander (6" x 80" and larger) | 5" | |

Drum Sander (24" and smaller) | 2 x 4" | |

Drum Sander (24" and larger) | 4 x 4" | |

Widebelt Sander (18" and smaller) | 5" | |

Widebelt Sander | 2 x 6" | |

Widebelt Sander (24"_51" double head).. | 5 x 4" | |

Figure 48. Dust port size and quantity per

average machine.

Write the required CFM for each machine on the sketch, as shown in Figure 49.

395 | 395 | 790 |

|

|

98

Determining Main Line Duct Diameter

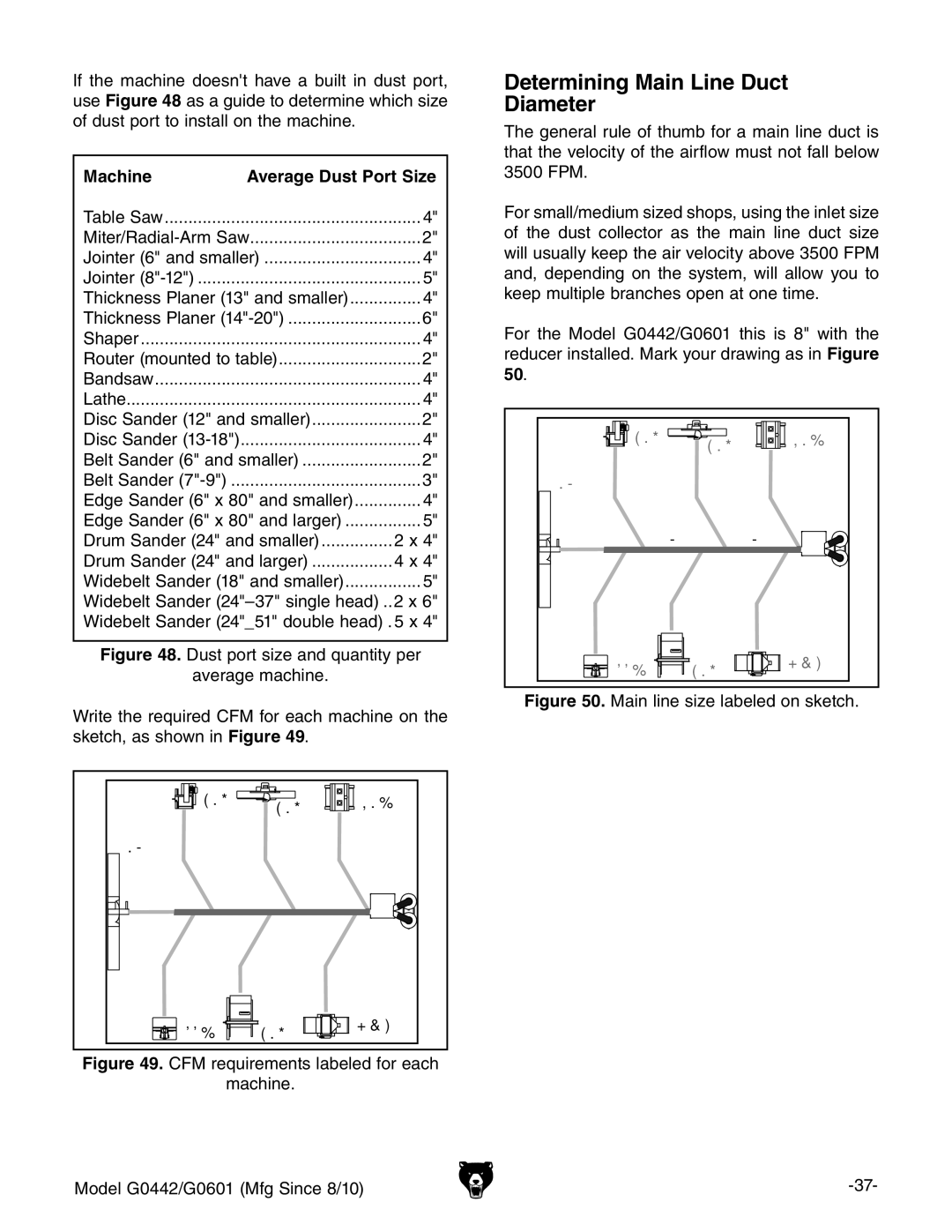

The general rule of thumb for a main line duct is that the velocity of the airflow must not fall below 3500 FPM.

For small/medium sized shops, using the inlet size of the dust collector as the main line duct size will usually keep the air velocity above 3500 FPM and, depending on the system, will allow you to keep multiple branches open at one time.

For the Model G0442/G0601 this is 8" with the reducer installed. Mark your drawing as in Figure 50.

395 | 395 | 790 |

|

|

98

8" 8"

220 | 395 | 614 |

|

Figure 50. Main line size labeled on sketch.

220 | 395 | 614 |

|

Figure 49. CFM requirements labeled for each

machine.

Model G0442/G0601 (Mfg Since 8/10) |