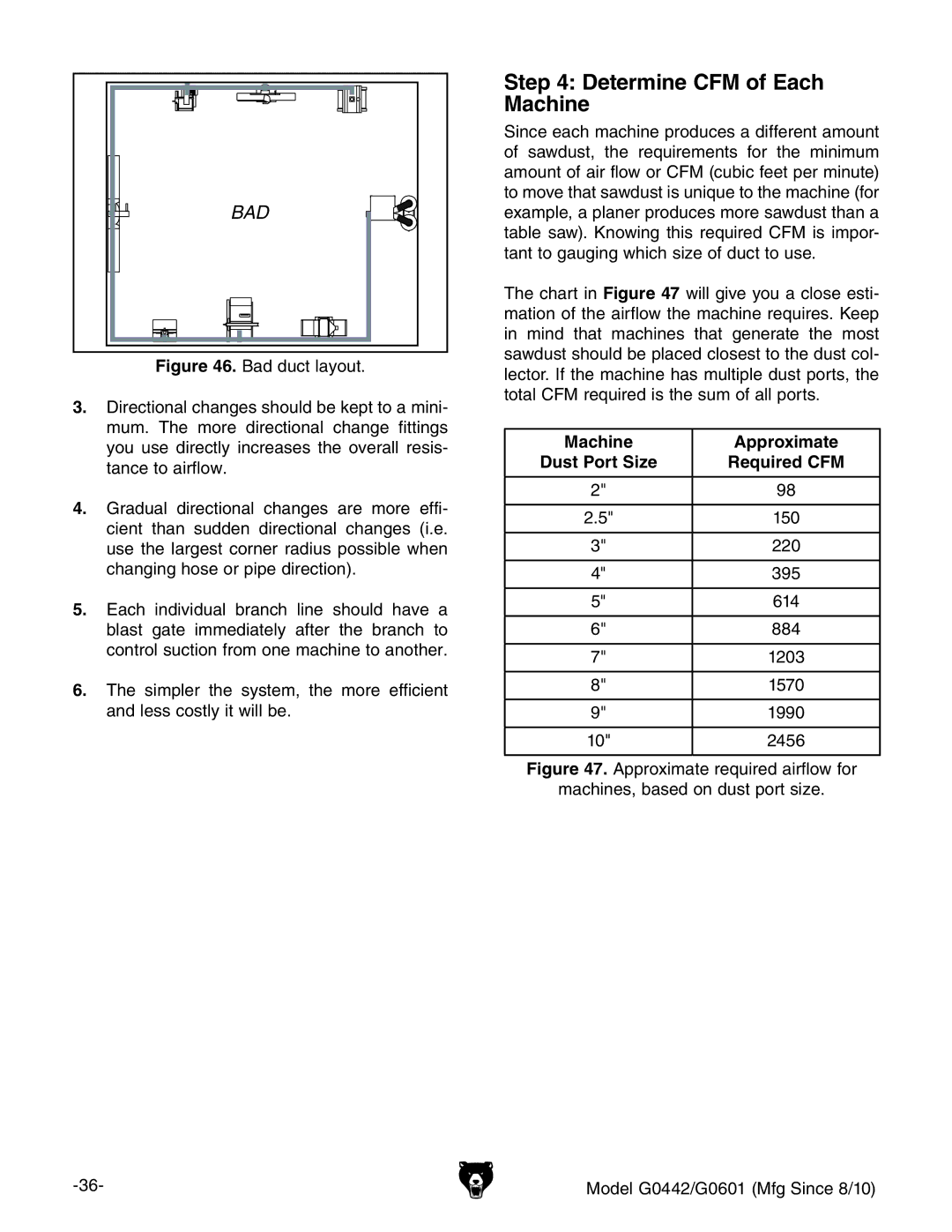

BAD |

Figure 46. Bad duct layout.

3.Directional changes should be kept to a mini- mum. The more directional change fittings you use directly increases the overall resis- tance to airflow.

4.Gradual directional changes are more effi- cient than sudden directional changes (i.e. use the largest corner radius possible when changing hose or pipe direction).

5.Each individual branch line should have a blast gate immediately after the branch to control suction from one machine to another.

6.The simpler the system, the more efficient and less costly it will be.

Step 4: Determine CFM of Each Machine

Since each machine produces a different amount of sawdust, the requirements for the minimum amount of air flow or CFM (cubic feet per minute) to move that sawdust is unique to the machine (for example, a planer produces more sawdust than a table saw). Knowing this required CFM is impor- tant to gauging which size of duct to use.

The chart in Figure 47 will give you a close esti- mation of the airflow the machine requires. Keep in mind that machines that generate the most sawdust should be placed closest to the dust col- lector. If the machine has multiple dust ports, the total CFM required is the sum of all ports.

Machine | Approximate |

Dust Port Size | Required CFM |

|

|

2" | 98 |

|

|

2.5" | 150 |

|

|

3" | 220 |

|

|

4" | 395 |

|

|

5" | 614 |

|

|

6" | 884 |

|

|

7" | 1203 |

|

|

8" | 1570 |

|

|

9" | 1990 |

|

|

10" | 2456 |

|

|

Figure 47. Approximate required airflow for

machines, based on dust port size.

Model G0442/G0601 (Mfg Since 8/10) |