Calculating Duct Resistance

Adding duct work, elbows, branches and any other components to a duct line increases airflow resistance (static pressure loss). This resistance can be minimized by using rigid (smooth) pipe and gradual curves, as opposed to flexible pipe and 90˚ elbows.

To help you think about this resistance, imagine riding a bicycle in a tunnel that is an exact replica of the duct work. If the inside of the tunnel is very bumpy (flexible pipe) and has a lot of sharp turns (90˚ elbows), it will take a lot more effort to travel from one end to the other.

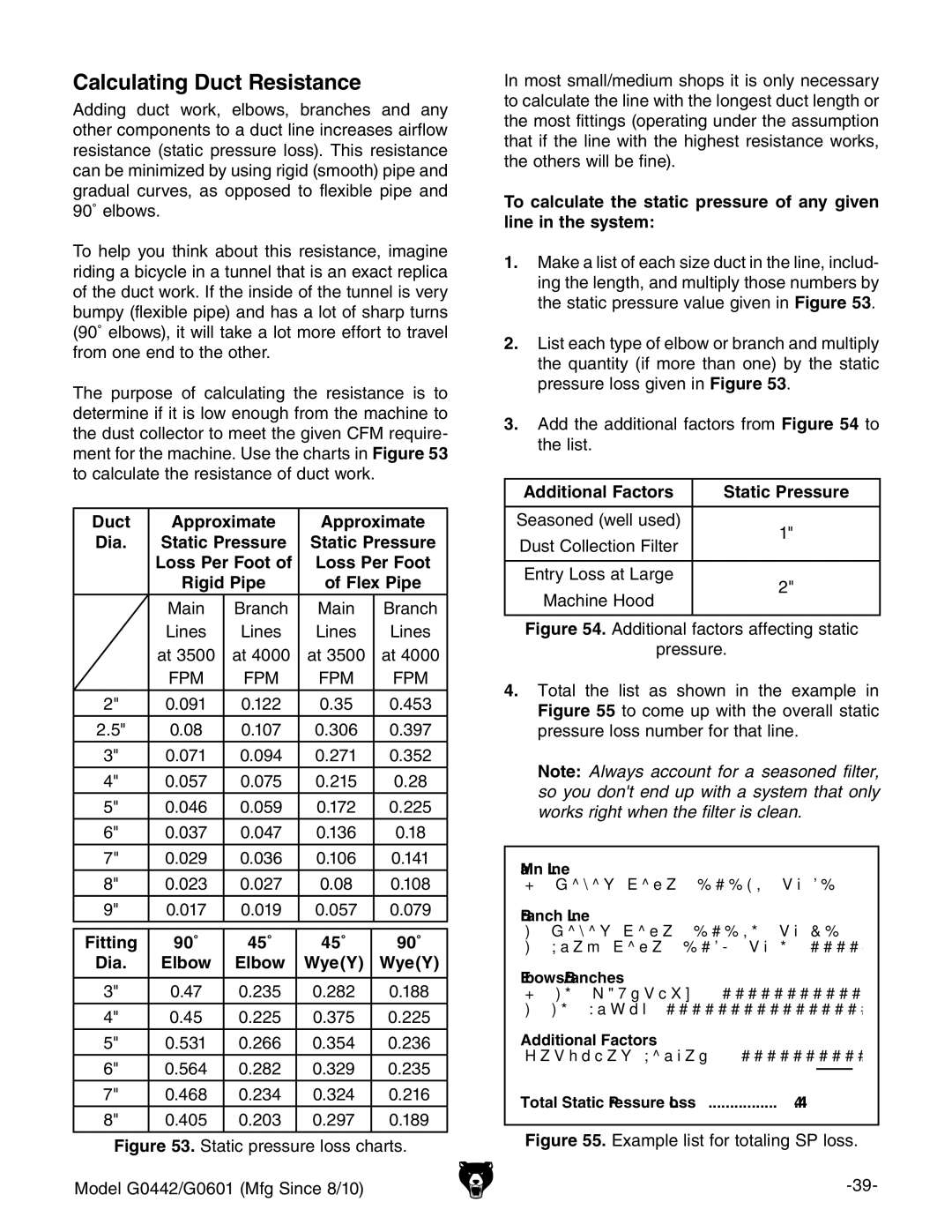

The purpose of calculating the resistance is to determine if it is low enough from the machine to the dust collector to meet the given CFM require- ment for the machine. Use the charts in Figure 53 to calculate the resistance of duct work.

Duct | Approximate | Approximate | ||

Dia. | Static Pressure | Static Pressure | ||

| Loss Per Foot of | Loss Per Foot | ||

| Rigid Pipe | of Flex Pipe | ||

| Main | Branch | Main | Branch |

| Lines | Lines | Lines | Lines |

| at 3500 | at 4000 | at 3500 | at 4000 |

| FPM | FPM | FPM | FPM |

2" | 0.091 | 0.122 | 0.35 | 0.453 |

2.5" | 0.08 | 0.107 | 0.306 | 0.397 |

3" | 0.071 | 0.094 | 0.271 | 0.352 |

4" | 0.057 | 0.075 | 0.215 | 0.28 |

5" | 0.046 | 0.059 | 0.172 | 0.225 |

6" | 0.037 | 0.047 | 0.136 | 0.18 |

7" | 0.029 | 0.036 | 0.106 | 0.141 |

8" | 0.023 | 0.027 | 0.08 | 0.108 |

9" | 0.017 | 0.019 | 0.057 | 0.079 |

|

|

|

|

|

Fitting | 90˚ | 45˚ | 45˚ | 90˚ |

Dia. | Elbow | Elbow | Wye(Y) | Wye(Y) |

|

|

|

|

|

3" | 0.47 | 0.235 | 0.282 | 0.188 |

4" | 0.45 | 0.225 | 0.375 | 0.225 |

5" | 0.531 | 0.266 | 0.354 | 0.236 |

|

|

|

|

|

6" | 0.564 | 0.282 | 0.329 | 0.235 |

|

|

|

|

|

7" | 0.468 | 0.234 | 0.324 | 0.216 |

|

|

|

|

|

8" | 0.405 | 0.203 | 0.297 | 0.189 |

|

|

|

|

|

Figure 53. Static pressure loss charts.

Model G0442/G0601 (Mfg Since 8/10)

In most small/medium shops it is only necessary to calculate the line with the longest duct length or the most fittings (operating under the assumption that if the line with the highest resistance works, the others will be fine).

To calculate the static pressure of any given line in the system:

1.Make a list of each size duct in the line, includ- ing the length, and multiply those numbers by the static pressure value given in Figure 53.

2.List each type of elbow or branch and multiply the quantity (if more than one) by the static pressure loss given in Figure 53.

3.Add the additional factors from Figure 54 to the list.

Additional Factors | Static Pressure | |

|

| |

Seasoned (well used) | 1" | |

Dust Collection Filter | ||

| ||

|

| |

Entry Loss at Large | 2" | |

Machine Hood | ||

| ||

|

|

Figure 54. Additional factors affecting static

pressure.

4.Total the list as shown in the example in Figure 55 to come up with the overall static pressure loss number for that line.

Note: Always account for a seasoned filter, so you don't end up with a system that only works right when the filter is clean.

Main Line |

|

|

6" Rigid Pipe (0.037) at 20' | 0.740 | |

Branch Line |

|

|

4" Rigid Pipe (0.075) at 10' | 0.750 | |

4" Flex Pipe (0.28) at 5' | 1.400 | |

Elbows/Branches |

|

|

6" 45˚ | 0.329 | |

4" 45˚ Elbow | 0.225 | |

Additional Factors |

|

|

Seasoned Filter | 1.000 | |

|

|

|

Total Static Pressure Loss | 4.444 | |