Length of | Max. Discharge | Max. Discharge | Length of | Max. Discharge | Max. Discharge |

Dryer | rate in BPH | rate in MT/hr | Dryer | rate in BPH | rate in MT/hr |

|

|

|

|

|

|

14 ft | 1960 | 50 | 20 ft | 2800 | 71 |

16 ft | 2240 | 57 | 22 ft | 3080 | 78 |

18 ft | 2520 | 64 | 26 ft | 3640 | 92 |

Note: When the control is set to the maximum discharge rate (999), the metering roll speed should be 17.5 RPM for 8" (20 cm) discharge auger.

2.DC electric motor: The direct current (DC) motor provides the drive for the metering roll, and is located on the front left hand side of standard model dryers. The output shaft of the motor is connected directly to the gear box assembly.The DC motor requires no operational adjustment as it is completely controlled from the control box.

3.Speed reducer gear box: The direct drive gear box providesthe required speed reduction, and transmits power to the metering rolls through a drive chain arrangement. The gear box does not require adjustment. The drive chain should also be periodically lubricated and retensioned as necessary.

4.Unload auger time delay: The delay controls the bottom auger system and causes the unload auger (and any connected auxiliary unloading conveyors) to continue operating for a programmed amount of time, even after the metering rolls stop. This feature permits the cleanout of grain within the unloading equipment at the end of all discharge cycles.

5.If a foreign object becomes lodged in the metering rolls and jams the system, the unloading auger will stay in motion. However, the metering roll drive will stop and the DC motor should stall out. The Network Control System will shut down the dryer after a two minute period.

To determine if the metering problem is from blockage, perform the following test with the power off. Remove the drive chain by loosening the motor mounting bolts. Refer to photo, and place a pipe wrench on the hub of the roller chain sprocket, on the left hand metering roll at the drive end of the dryer. Apply up to 100 ft.lbs. (136

CAUTION: Keep hands away from sprocket teeth to avoid injury from chain backlash, as a result of torsion build up in the system caused by the jam.

HOW TO CLEAR A JAMMED METERING ROLL

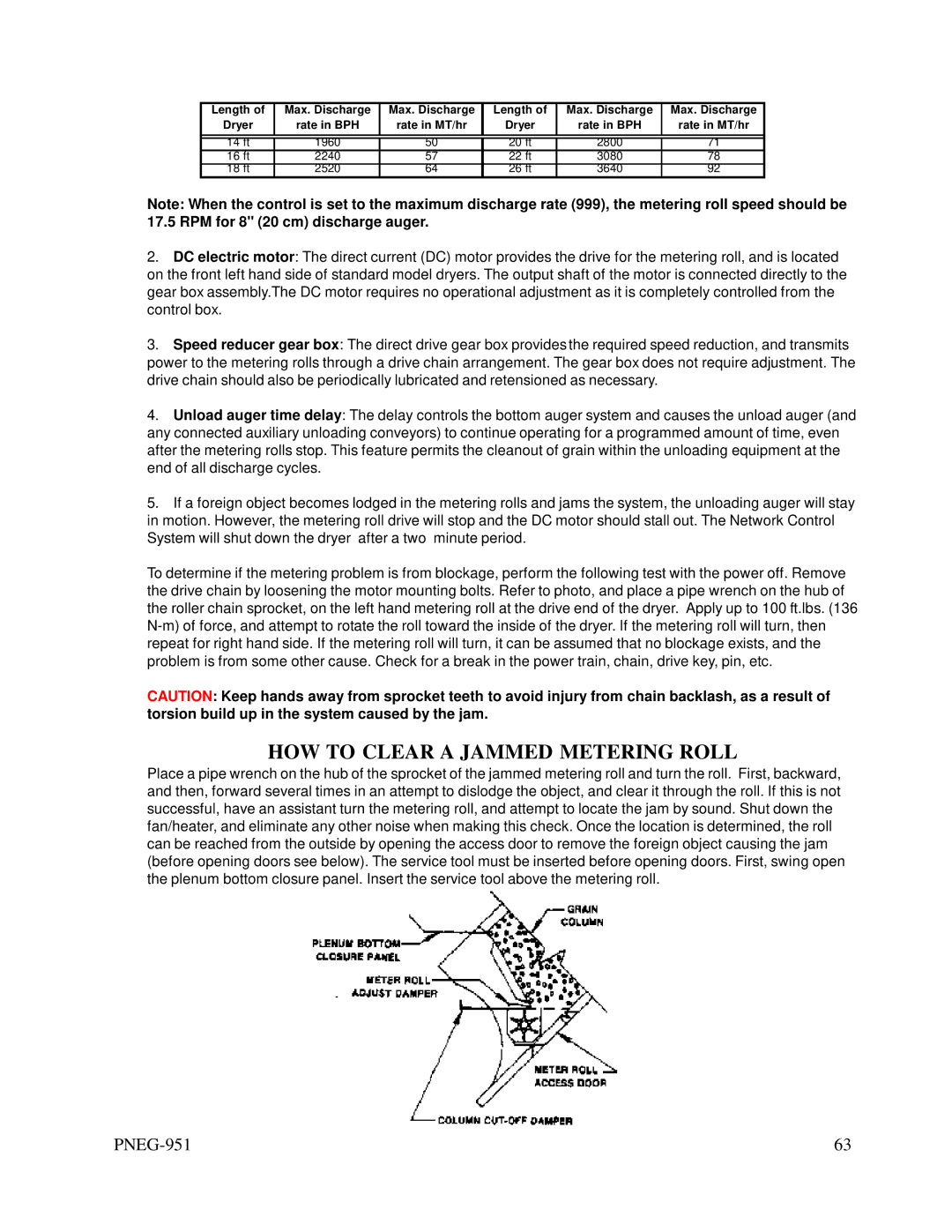

Place a pipe wrench on the hub of the sprocket of the jammed metering roll and turn the roll. First, backward, and then, forward several times in an attempt to dislodge the object, and clear it through the roll. If this is not successful, have an assistant turn the metering roll, and attempt to locate the jam by sound. Shut down the fan/heater, and eliminate any other noise when making this check. Once the location is determined, the roll can be reached from the outside by opening the access door to remove the foreign object causing the jam (before opening doors see below). The service tool must be inserted before opening doors. First, swing open the plenum bottom closure panel. Insert the service tool above the metering roll.

| 63 |