User Guide

User Notice

Ioline Flexjet E Printers

Table of Contents

Routine Maintenance

Glossary Index

Page

Page

Safety & Cautions

Visual Reference Guide

KM N

AB C D E F

Getting Started

Chapter

Ioline FlexJet E User Guide

How The Ioline FlexJet E and StudioJet printers Work

Unpacking the Printer

Printer Assembly

Assembling the Stand

Attaching the Printer to the Stand

COM Port

Serial Configuration

Cable Connections

Software Setup Options

Other Serial Port Settings

Installation

Baud Rate

CAD

Installing FlexPlot and the Control Center

Power On

This page intentionally left blank

Start/Stop

Keypad Controls

Set Origin

Clean

Quality

Special Key Combinations

Variety of settings are adjustable to fit specific needs

Changing System Settings

Control Center

Overview

File

Control Center Menu Bar Features

Communications

Tools

Control Center Menu Options

Consumables

Send marker/plot files

Printing a Marker

General Guidelines

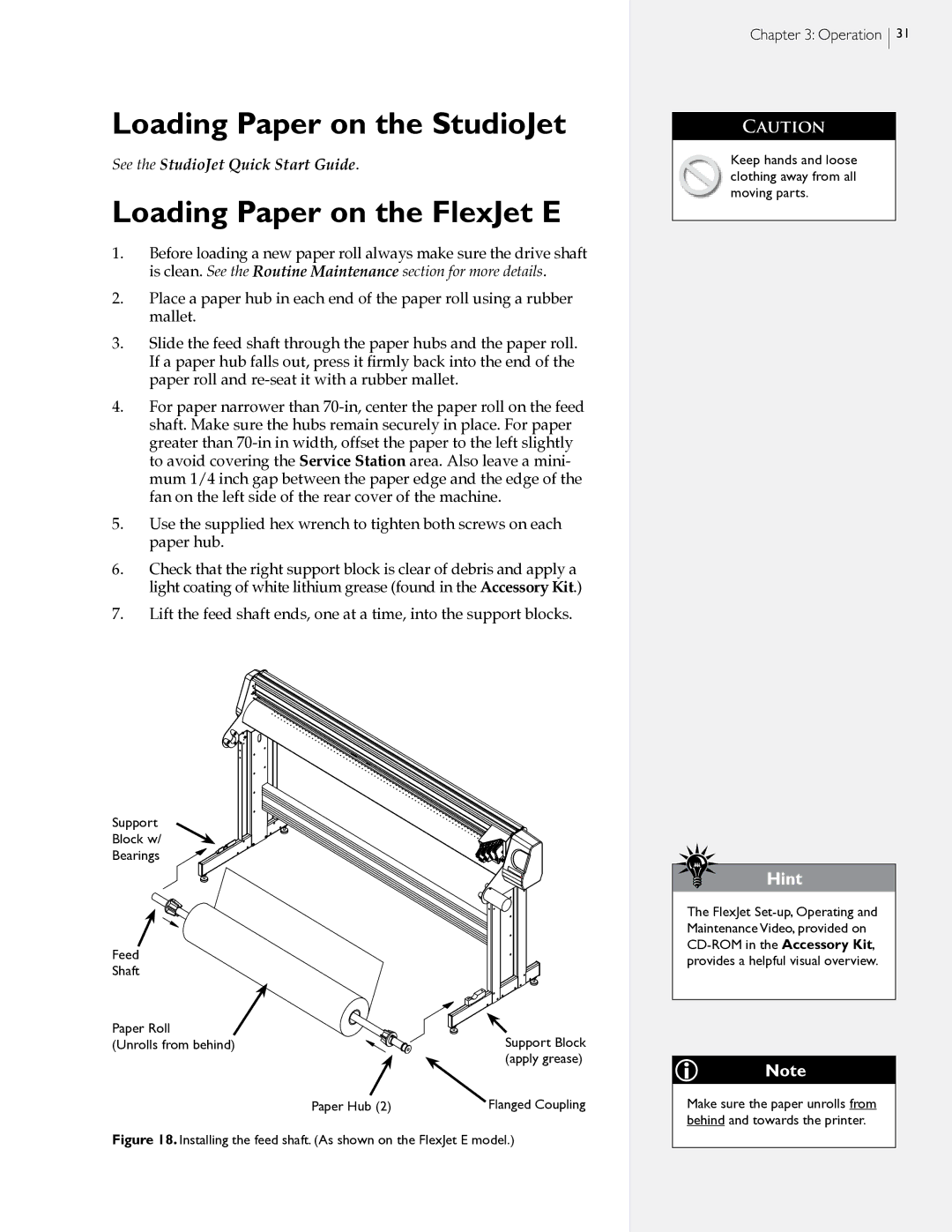

Loading Paper on the FlexJet E

Loading Paper on the StudioJet

FlexJet E only

Installing the Take-up Shaft

2H+ FlexJet E

Feeding Paper

Positioning the Pinchwheels

Tape Paper to theTake-up Shaft

Positioning the pinchwheels

Insert Front Dancer Bar

Insert Rear Dancer Bar2H+ FJE Models Only

Pausing a Marker Plot

Set an Origin

Sending Plot Files

Removing Markers from the Take-up Shaft

Canceling a Marker Plot

Manually freeing the take-up shaft

Manually Freeing Take-up Shaft

Reattach Paper To the Take-up Shaft

Automatically Freeing the Take-Up Shaft

Printing to the Floor

Cleaning the Platen and Traverse

Cleaning the Drive Shaft

Prepare the Printer See the Operation chapter

Cleaning the Support Blocks

Size Calibration

Enter the Calibration Data

Click on Done when finished Routine Maintenance

Use the Control Center to Gather the Calibration Data

Prepare the Printer

Cartridge Calibration

Frame Gap Paper Scan Alignment

Motion Adjust Carriage Scan Alignment

Click on Done when finished

Check Cartridges

Cartridge Maintenance and Handling

Automatic Cleaning Procedure

Open the latch for the first cartridge and remove it

Manual Cleaning Procedure

Soft, fiberless, and moistened with deionized water

Print Cartridge Storage

Update the Firmware

Reset Calibration Values

Media Tracking

General Troubleshooting

Serial Communication

Printing Quality

Line Quality

Troubleshooting

Keypad Error Codes

Printer does not complete the marker Cause

Common Issues

Quick Start Guide to level

Regular or intermittent paper tearing Cause

FlexJet E Models only

This page intentionally left blank

Getting Help

Service & Support

700 A.M. 500 P.M. U.S. Pacific Time

Customer Service

Your Comments Are Requested

End Notes

Before you contact Support…

This booklet is available from

FCC WantsYou to Know

Glossary

Panel See Frame

Glossary

This page intentionally left blank

Calibration 27, 42-46, 49

Clean ix, 24, 33, 41, 46

Arrow keys ix, 23, 24, 25, 37, 42, 44

DM/PL 15, 19, 20

Baud rate 18, 19, 25, 27, 28, 44, 52

Design software 15, 17, 19, 24, 28, 36, 51, 52, 54, 57, 61

File formats 15, 19, 20

Feed shaft x, 30, 31, 35, 42, 55, 63

EPS 27 PLT 27 PLX 27

Index

Set origin 24, 36, 37, 42, 44, 54, 56

Stalls xii, 29

Media 15, 16, 51

Origin 16, 21, 24, 36, 37, 42, 44, 53, 54, 56

Power switch xi, xiv, 21

Power cord xiv, 18, 21, 41

Platen xi, xii, xiii, 33, 41, 55, 56

Frame 16, 28, 54

Stop mode 23, 24, 25, 29, 37, 50

Service Station ix, xii, 21, 24, 33, 36, 46, 48, 50, 53

Sensor xii, 25

Serial port xi, xiv, 15, 17, 18, 19, 25, 52

USB xi Index

Traverse xii, 41

Unroll v, 23, 25, 32, 37, 39, 50

31

31