Kirby Morgan 37 & 57

7.6 Bent Tube Assembly

7.6.1 General

The bent tube assembly provides breathing gas flow from the side block assembly to the regulator assembly on the Kirby Morgan 37. Both ends of the bent tube assembly disconnect for complete removal. The O- ring and the Teflon

These components do not require replacement during field repairs providing a careful visual inspection does not reveal wear or damage. All soft goods should be carefully cleaned in accordance with Chapter 6 prior to inspection for reuse.

7.6.2Removal of the Bent Tube Assembly

Tools Required:

11/16 inch

7/8 inch

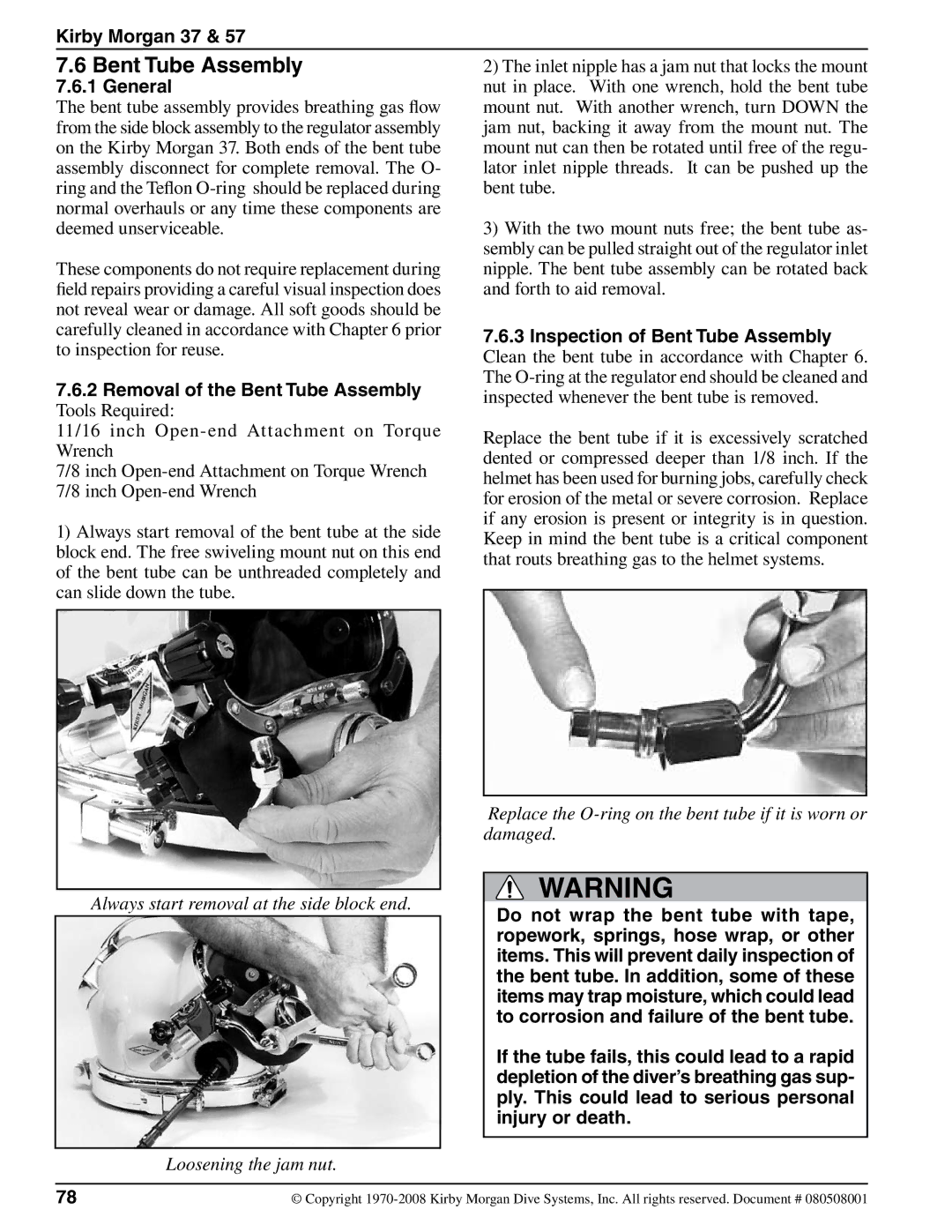

1)Always start removal of the bent tube at the side block end. The free swiveling mount nut on this end of the bent tube can be unthreaded completely and can slide down the tube.

2)The inlet nipple has a jam nut that locks the mount nut in place. With one wrench, hold the bent tube mount nut. With another wrench, turn DOWN the jam nut, backing it away from the mount nut. The mount nut can then be rotated until free of the regu- lator inlet nipple threads. It can be pushed up the bent tube.

3)With the two mount nuts free; the bent tube as- sembly can be pulled straight out of the regulator inlet nipple. The bent tube assembly can be rotated back and forth to aid removal.

7.6.3Inspection of Bent Tube Assembly

Clean the bent tube in accordance with Chapter 6. The

Replace the bent tube if it is excessively scratched dented or compressed deeper than 1/8 inch. If the helmet has been used for burning jobs, carefully check for erosion of the metal or severe corrosion. Replace if any erosion is present or integrity is in question. Keep in mind the bent tube is a critical component that routs breathing gas to the helmet systems.

Always start removal at the side block end.

Loosening the jam nut.

Replace the

![]() WARNING

WARNING

Do not wrap the bent tube with tape, ropework, springs, hose wrap, or other items. This will prevent daily inspection of the bent tube. In addition, some of these items may trap moisture, which could lead to corrosion and failure of the bent tube.

If the tube fails, this could lead to a rapid depletion of the diver’s breathing gas sup- ply. This could lead to serious personal injury or death.

78 | © Copyright |