Kirby Morgan 37 & 57

7.7.10Tuning the SuperFlow 350 Regulator

1) Remove the clamp, cover and diaphragm.

2)Screw the adjustment knob (clockwise) all the way in, towards the regulator body.

3)Pressurize the regulator to between

4)Screw the adjustment knob out (counterclockwise) until the regulator starts to free flow, then screw the adjustment knob in (clockwise) until the

If the free flow does not stop, the adjustment nut is too tight. If the roller lever is sloppy (loose) the ad- justment nut is too loose.

5)Insert the inlet valve holding tool into the balance hole on the inlet tube. Push forward on the tool to stop the inlet valve stem from turning. Adjust the nut until there is 1/16 inch (1.5 mm) to 1/8 inch (3.0 mm) of free play at the end of the lever.

Insert the inlet valve holding tool into the balance hole on the inlet tube.

6)Remove the inlet valve holder tool.

7)Put the diaphragm and cover in place, depressing the cover tightly to simulate a properly tightened clamp.

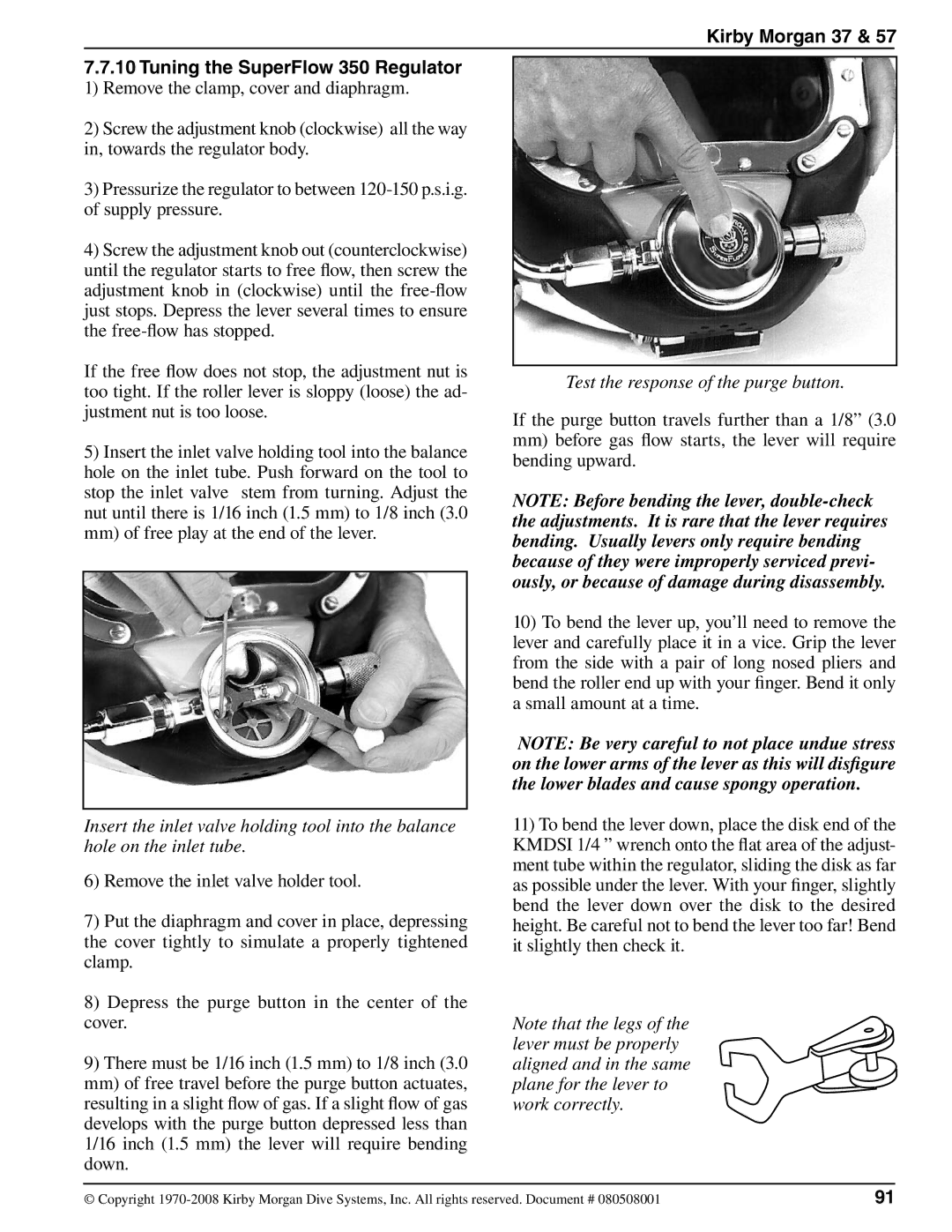

8)Depress the purge button in the center of the cover.

9)There must be 1/16 inch (1.5 mm) to 1/8 inch (3.0 mm) of free travel before the purge button actuates, resulting in a slight flow of gas. If a slight flow of gas develops with the purge button depressed less than 1/16 inch (1.5 mm) the lever will require bending down.

Test the response of the purge button.

If the purge button travels further than a 1/8” (3.0

mm)before gas flow starts, the lever will require bending upward.

NOTE: Before bending the lever,

10)To bend the lever up, you’ll need to remove the lever and carefully place it in a vice. Grip the lever from the side with a pair of long nosed pliers and bend the roller end up with your finger. Bend it only a small amount at a time.

NOTE: Be very careful to not place undue stress on the lower arms of the lever as this will disfigure the lower blades and cause spongy operation.

11)To bend the lever down, place the disk end of the KMDSI 1/4 ” wrench onto the flat area of the adjust- ment tube within the regulator, sliding the disk as far as possible under the lever. With your finger, slightly bend the lever down over the disk to the desired height. Be careful not to bend the lever too far! Bend it slightly then check it.

Note that the legs of the lever must be properly aligned and in the same plane for the lever to work correctly.

© Copyright | 91 |