Kirby Morgan 37 & 57

7.7.8 Inspection of SuperFlow 350 | nipple | ||

Demand Regulator Parts | inlet nipple as well as the soft seat will require replace- | ||

After the regulator has been disassembled, clean and | ment. During annual overhaul the inlet valve soft seat | ||

inspect all parts. Any parts showing signs of wear, | should be replaced. | ||

damage or deterioration should be replaced. If this |

| ||

is an annual overhaul KMDSI recommends replace- | 3) Inlet Valve Soft Seat Replacement: To replace the | ||

ment of the inlet valve seat, adjustment nut, | soft seat use a small screwdriver or | ||

on inlet valve, | the soft seat from the chrome plated brass valve body. | ||

on the adjustment shaft. A rebuild kit is available for | Using a sewing needle clean all old silicone sealant | ||

replacement parts (Part | from the vent hole in the bottom of the cup area, and | ||

|

| from the cupped area itself. Note: Replace the entire | |

If any parts show any signs of damage, deterioration | inlet valve if any chrome is missing or if the shaft is | ||

or any damaged threads, the part should be replaced. | bent or thread damage is present. | ||

The adjustment nut must never be reused. Reuse of |

| ||

the adjustment nut will not allow the regulator to | 4) Dab a small amount of silicone adhesive Dow | ||

maintain proper adjustment. | Corning 732 or equivalent on one side of the new | ||

|

| soft seat then press the seat into the cup area of the | |

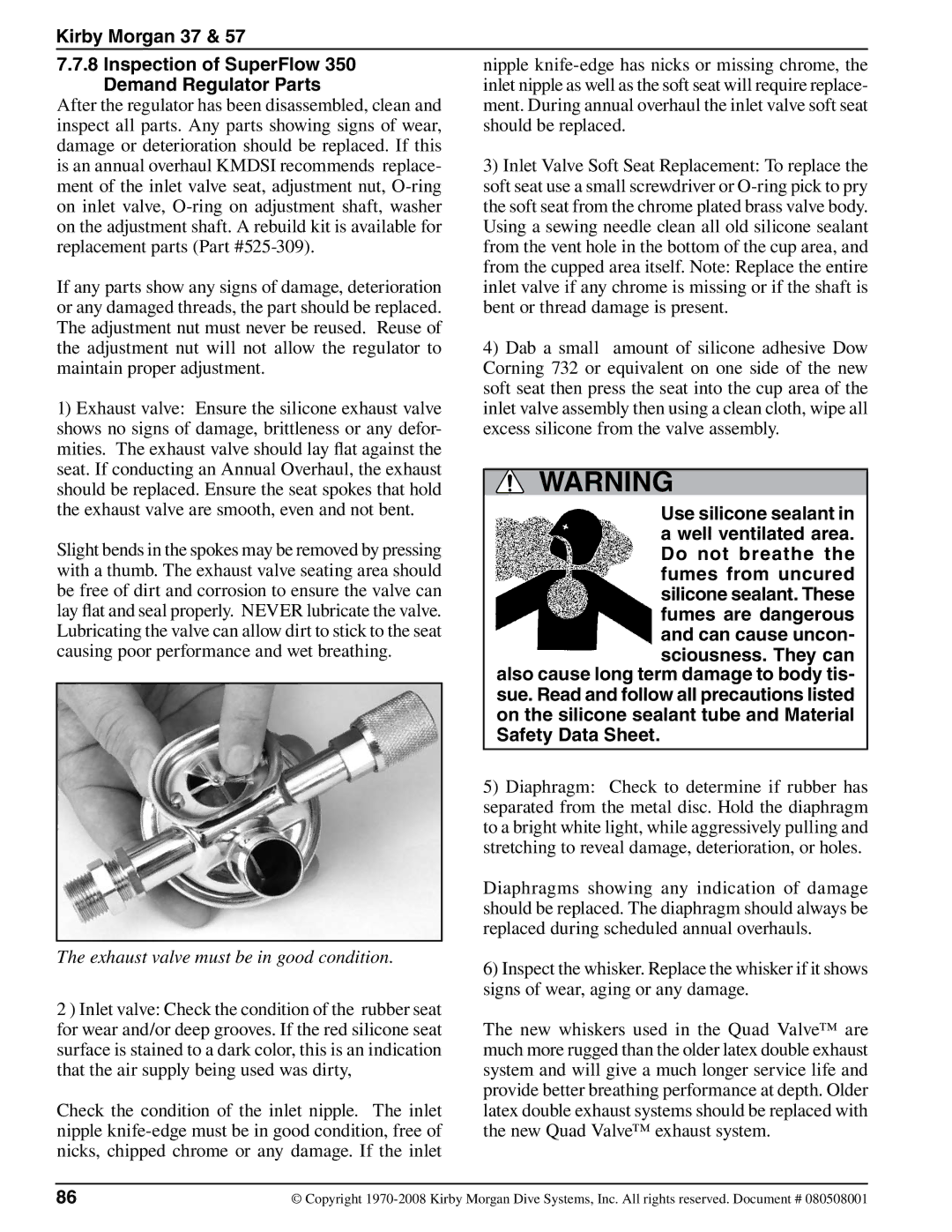

1) Exhaust valve: Ensure the silicone exhaust valve | inlet valve assembly then using a clean cloth, wipe all | ||

shows no signs of damage, brittleness or any defor- | excess silicone from the valve assembly. | ||

mities. The exhaust valve should lay flat against the |

| ||

seat. If conducting an Annual Overhaul, the exhaust |

| ||

WARNING | |||

should be replaced. Ensure the seat spokes that hold | |||

the exhaust valve are smooth, even and not bent. | Use silicone sealant in | ||

Slight bends in the spokes may be removed by pressing | a well ventilated area. | ||

Do not breathe the | |||

with a thumb. The exhaust valve seating area should | fumes from uncured | ||

be free of dirt and corrosion to ensure the valve can | silicone sealant. These | ||

lay flat and seal properly. NEVER lubricate the valve. | fumes are dangerous | ||

Lubricating the valve can allow dirt to stick to the seat | and can cause uncon- | ||

causing poor performance and wet breathing. | sciousness. They can | ||

|

| also cause long term damage to body tis- | |

|

| sue. Read and follow all precautions listed | |

|

| on the silicone sealant tube and Material | |

|

| Safety Data Sheet. | |

|

| 5) Diaphragm: Check to determine if rubber has | |

|

| separated from the metal disc. Hold the diaphragm | |

|

| to a bright white light, while aggressively pulling and | |

|

| stretching to reveal damage, deterioration, or holes. | |

|

| Diaphragms showing any indication of damage | |

|

| should be replaced. The diaphragm should always be | |

|

| replaced during scheduled annual overhauls. | |

|

|

| |

The exhaust valve must be in good condition. | 6) Inspect the whisker. Replace the whisker if it shows | ||

|

| ||

2 ) Inlet valve: Check the condition of the rubber seat | signs of wear, aging or any damage. | ||

The new whiskers used in the Quad Valve™ are | |||

for wear and/or deep grooves. If the red silicone seat | |||

surface is stained to a dark color, this is an indication | much more rugged than the older latex double exhaust | ||

that the air supply being used was dirty, | system and will give a much longer service life and | ||

|

| provide better breathing performance at depth. Older | |

Check the condition of the inlet nipple. The inlet | latex double exhaust systems should be replaced with | ||

nipple | the new Quad Valve™ exhaust system. | ||

nicks, chipped chrome or any damage. If the inlet |

| ||

86 | © Copyright |