Kirby Morgan 37 & 57

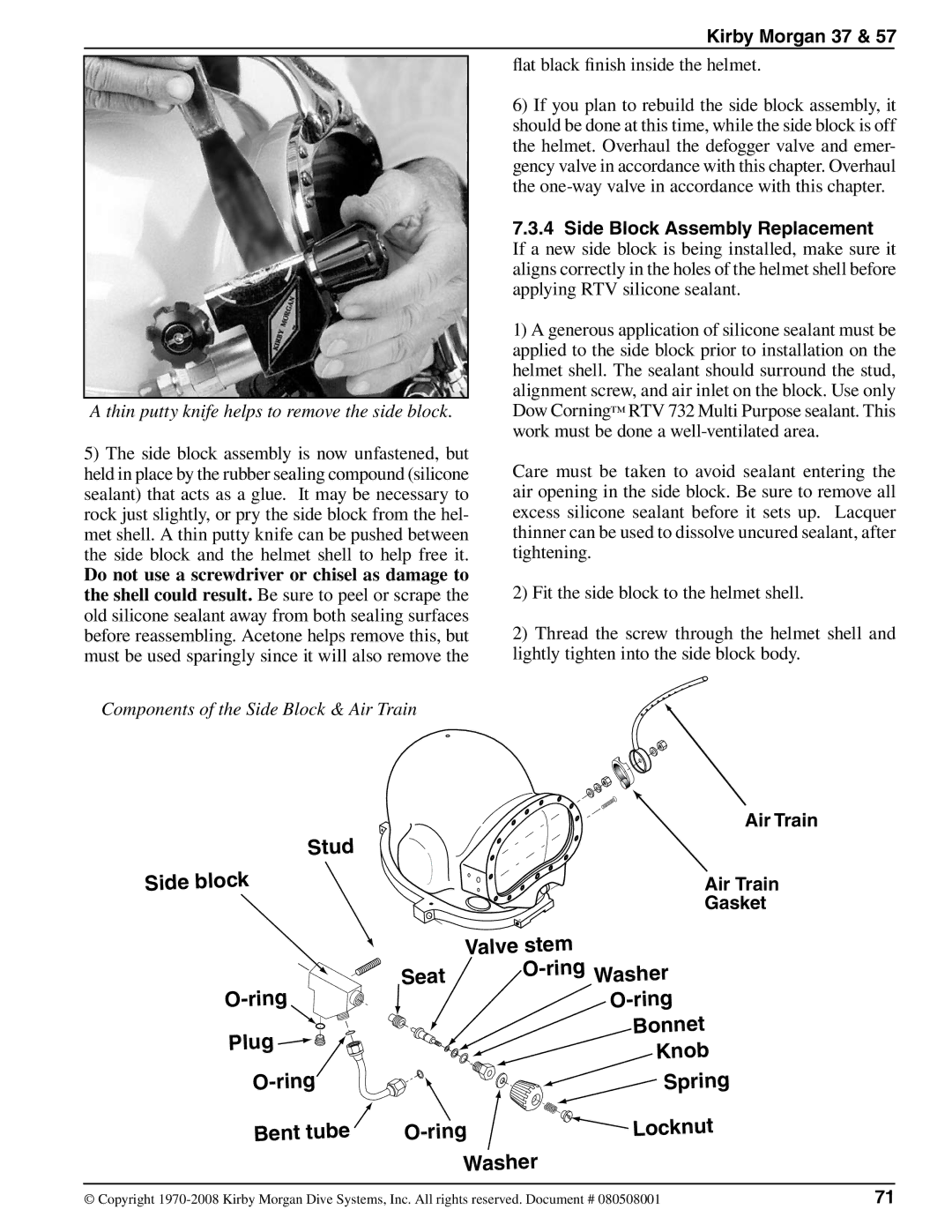

A thin putty knife helps to remove the side block.

5)The side block assembly is now unfastened, but held in place by the rubber sealing compound (silicone sealant) that acts as a glue. It may be necessary to rock just slightly, or pry the side block from the hel- met shell. A thin putty knife can be pushed between the side block and the helmet shell to help free it.

Do not use a screwdriver or chisel as damage to the shell could result. Be sure to peel or scrape the old silicone sealant away from both sealing surfaces before reassembling. Acetone helps remove this, but must be used sparingly since it will also remove the

flat black finish inside the helmet.

6)If you plan to rebuild the side block assembly, it should be done at this time, while the side block is off the helmet. Overhaul the defogger valve and emer- gency valve in accordance with this chapter. Overhaul the

7.3.4 Side Block Assembly Replacement If a new side block is being installed, make sure it aligns correctly in the holes of the helmet shell before applying RTV silicone sealant.

1)A generous application of silicone sealant must be applied to the side block prior to installation on the helmet shell. The sealant should surround the stud, alignment screw, and air inlet on the block. Use only Dow Corning™ RTV 732 Multi Purpose sealant. This work must be done a

Care must be taken to avoid sealant entering the air opening in the side block. Be sure to remove all excess silicone sealant before it sets up. Lacquer thinner can be used to dissolve uncured sealant, after tightening.

2) Fit the side block to the helmet shell.

2)Thread the screw through the helmet shell and lightly tighten into the side block body.

Components of the Side Block & Air Train

Stud Side block

Plug ![]()

![]()

![]()

![]()

Bent tube

Air Train

Air Train

Gasket

| Valve stem |

|

Seat |

| Washer |

| ||

|

| |

|

| t |

|

| Bonne |

|

| Knob |

|

| Spring |

|

| knut |

| g | Loc |

| ||

| Washer |

|

© Copyright | 71 |