| ROBOTIC INTERFACE | |||||

|

|

|

| |||

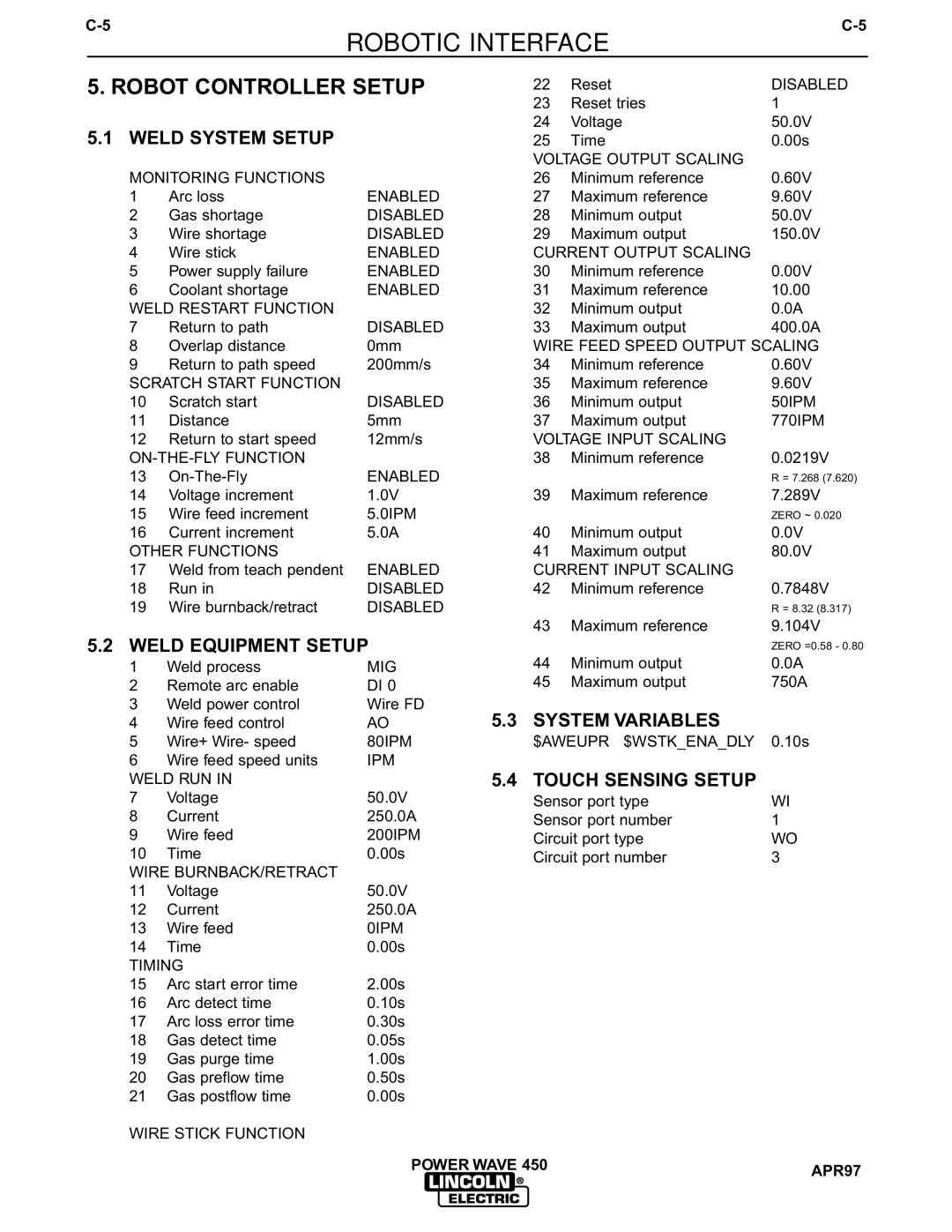

| 5. ROBOT CONTROLLER SETUP | 22 | Reset | DISABLED | ||

|

|

|

| 23 | Reset tries | 1 |

| 5.1 WELD SYSTEM SETUP |

| 24 | Voltage | 50.0V | |

|

| 25 | Time | 0.00s | ||

|

|

|

| VOLTAGE OUTPUT SCALING |

| |

| MONITORING FUNCTIONS |

| 26 | Minimum reference | 0.60V | |

1 | Arc loss | ENABLED | 27 | Maximum reference | 9.60V | |

2 | Gas shortage | DISABLED | 28 | Minimum output | 50.0V | |

3 | Wire shortage | DISABLED | 29 | Maximum output | 150.0V | |

4 | Wire stick | ENABLED | CURRENT OUTPUT SCALING |

| ||

5 | Power supply failure | ENABLED | 30 | Minimum reference | 0.00V | |

6 | Coolant shortage | ENABLED | 31 | Maximum reference | 10.00 | |

| WELD RESTART FUNCTION |

| 32 | Minimum output | 0.0A | |

7 | Return to path | DISABLED | 33 | Maximum output | 400.0A | |

8 | Overlap distance | 0mm | WIRE FEED SPEED OUTPUT SCALING | |||

9 | Return to path speed | 200mm/s | 34 | Minimum reference | 0.60V | |

| SCRATCH START FUNCTION |

| 35 | Maximum reference | 9.60V | |

10 | Scratch start | DISABLED | 36 | Minimum output | 50IPM | |

11 | Distance | 5mm | 37 | Maximum output | 770IPM | |

12 | Return to start speed | 12mm/s | VOLTAGE INPUT SCALING |

| ||

|

| 38 | Minimum reference | 0.0219V | ||

13 | ENABLED |

|

| R = 7.268 (7.620) | ||

14 | Voltage increment | 1.0V | 39 | Maximum reference | 7.289V | |

15 | Wire feed increment | 5.0IPM |

|

| ZERO ~ 0.020 | |

16 | Current increment | 5.0A | 40 | Minimum output | 0.0V | |

| OTHER FUNCTIONS |

| 41 | Maximum output | 80.0V | |

17 | Weld from teach pendent | ENABLED | CURRENT INPUT SCALING |

| ||

18 | Run in | DISABLED | 42 | Minimum reference | 0.7848V | |

19 | Wire burnback/retract | DISABLED |

|

| R = 8.32 (8.317) | |

|

|

|

| 43 | Maximum reference | 9.104V |

5.2 WELD EQUIPMENT SETUP

1 | Weld process | MIG |

2 | Remote arc enable | DI 0 |

3 | Weld power control | Wire FD |

4 | Wire feed control | AO |

5 | Wire+ Wire- speed | 80IPM |

6 | Wire feed speed units | IPM |

WELD RUN IN |

| |

7 | Voltage | 50.0V |

8 | Current | 250.0A |

9 | Wire feed | 200IPM |

10 | Time | 0.00s |

WIRE BURNBACK/RETRACT |

| |

11 | Voltage | 50.0V |

12 | Current | 250.0A |

13 | Wire feed | 0IPM |

14 | Time | 0.00s |

TIMING |

| |

15 | Arc start error time | 2.00s |

16 | Arc detect time | 0.10s |

17 | Arc loss error time | 0.30s |

18 | Gas detect time | 0.05s |

19 | Gas purge time | 1.00s |

20 | Gas preflow time | 0.50s |

21 | Gas postflow time | 0.00s |

WIRE STICK FUNCTION

|

| ZERO =0.58 - 0.80 |

44 | Minimum output | 0.0A |

45 | Maximum output | 750A |

5.3 | SYSTEM VARIABLES |

|

| $AWEUPR $WSTK_ENA_DLY 0.10s | |

5.4 | TOUCH SENSING SETUP |

|

| Sensor port type | WI |

| Sensor port number | 1 |

| Circuit port type | WO |

| Circuit port number | 3 |

POWER WAVE 450 | APR97 |

|