OPERATION

ROBOTIC INTERFACE WELD FROM MEMORY, DUAL PROCEDURE OVERLAY

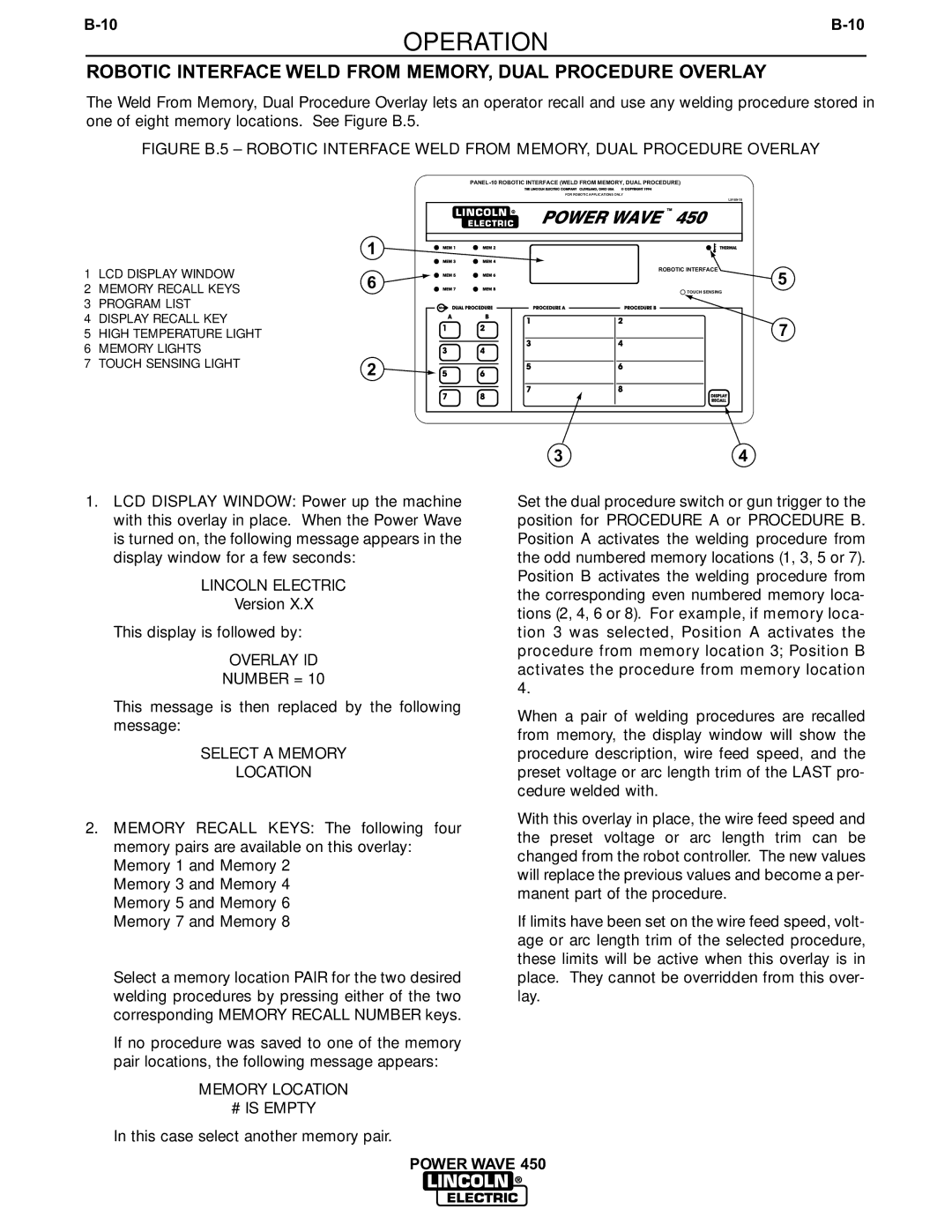

The Weld From Memory, Dual Procedure Overlay lets an operator recall and use any welding procedure stored in one of eight memory locations. See Figure B.5.

FIGURE B.5 – ROBOTIC INTERFACE WELD FROM MEMORY, DUAL PROCEDURE OVERLAY

FOR ROBOTIC APPLICATIONS ONLY

1LCD DISPLAY WINDOW

2MEMORY RECALL KEYS

3PROGRAM LIST

4DISPLAY RECALL KEY

5HIGH TEMPERATURE LIGHT

6MEMORY LIGHTS

7TOUCH SENSING LIGHT

1 ![]()

6 | ROBOTIC INTERFACE | 5 |

TOUCH SENSING |

7 |

2 |

34

1.LCD DISPLAY WINDOW: Power up the machine with this overlay in place. When the Power Wave is turned on, the following message appears in the display window for a few seconds:

LINCOLN ELECTRIC

Version X.X

This display is followed by:

OVERLAY ID

NUMBER = 10

This message is then replaced by the following message:

SELECT A MEMORY

LOCATION

Set the dual procedure switch or gun trigger to the position for PROCEDURE A or PROCEDURE B. Position A activates the welding procedure from the odd numbered memory locations (1, 3, 5 or 7). Position B activates the welding procedure from the corresponding even numbered memory loca- tions (2, 4, 6 or 8). For example, if memory loca- tion 3 was selected, Position A activates the procedure from memory location 3; Position B activates the procedure from memory location 4.

When a pair of welding procedures are recalled from memory, the display window will show the procedure description, wire feed speed, and the preset voltage or arc length trim of the LAST pro- cedure welded with.

2.MEMORY RECALL KEYS: The following four memory pairs are available on this overlay: Memory 1 and Memory 2

Memory 3 and Memory 4 Memory 5 and Memory 6 Memory 7 and Memory 8

Select a memory location PAIR for the two desired welding procedures by pressing either of the two corresponding MEMORY RECALL NUMBER keys.

If no procedure was saved to one of the memory pair locations, the following message appears:

MEMORY LOCATION

# IS EMPTY

In this case select another memory pair.

With this overlay in place, the wire feed speed and the preset voltage or arc length trim can be changed from the robot controller. The new values will replace the previous values and become a per- manent part of the procedure.

If limits have been set on the wire feed speed, volt- age or arc length trim of the selected procedure, these limits will be active when this overlay is in place. They cannot be overridden from this over- lay.