OPERATION

When the “WATER COOLER PRESSURE” light turns on, release the key.

5.WIRE FEEDER 1 +/- POLARITY KEY: Press this key to change the present voltage sensing polari- ty of wire feeder 1. The present polarity of wire feeder 1 is indicated by the “WIRE FEEDER 1+ POLARITY” light. If wire feeder 1 is set for positive voltage sensing polarity, this light is turned on.

6.WIRE FEEDER 1 ELECTRODE SENSE LEAD KEY: Press this key to enable or disable the elec- trode sense lead (lead #67) of wire feeder 1. When enabled, voltage sensing is done by the electrode sense lead. When disabled, voltage sensing is done at the Power Wave output terminal. When enabled, the “WIRE FEEDER 1 ELECTRODE SENSE LEAD ENABLED” light will be illuminated.

7.WIRE FEEDER 1 WORK SENSE LEAD KEY: Use this key to disable work sense (21) lead sensing in all robotic applications. Press this key until the

“WIRE FEEDER 1 WORK SENSE LEAD ENABLED” LED is OFF.

8.WIRE FEEDER 2: controls are used for touch sensing. They must be set to + polarity, electrode sense lead enabled and work sense lead disabled.

WIRE FEEDER SETUP DESCRIPTION

The Power Wave may be set up for either positive or negative arc voltage sensing using any two of the following places:

1.the positive output terminal of the Power Wave

2.the negative output terminal of the Power Wave

3.the electrode sense lead (67 lead) of the wire feeder

The SETUP Overlay allows you to select between which two places arc voltage will be sensed. Once the selection is made it is not necessary to reconfirm the selection every time a new overlay is used or a wire feeder is replaced with another one. The selection will remain until it is changed with the SETUP Overlay.

When welding with a stick procedure, the arc volt- age is automatically measured between the Power Wave’s output studs.

+/- POLARITY KEY

A.Positive Polarity Voltage Sensing :

In most welding applications the electrode cable is connected to the + output terminal and the work cable is connected to the - output terminal of the power source. This is positive polarity voltage sensing. When the Power Wave and the wire feeder(s) are connected in this manner, the arc voltage can be measured in one of two ways. These two ways are shown in Table B.1.

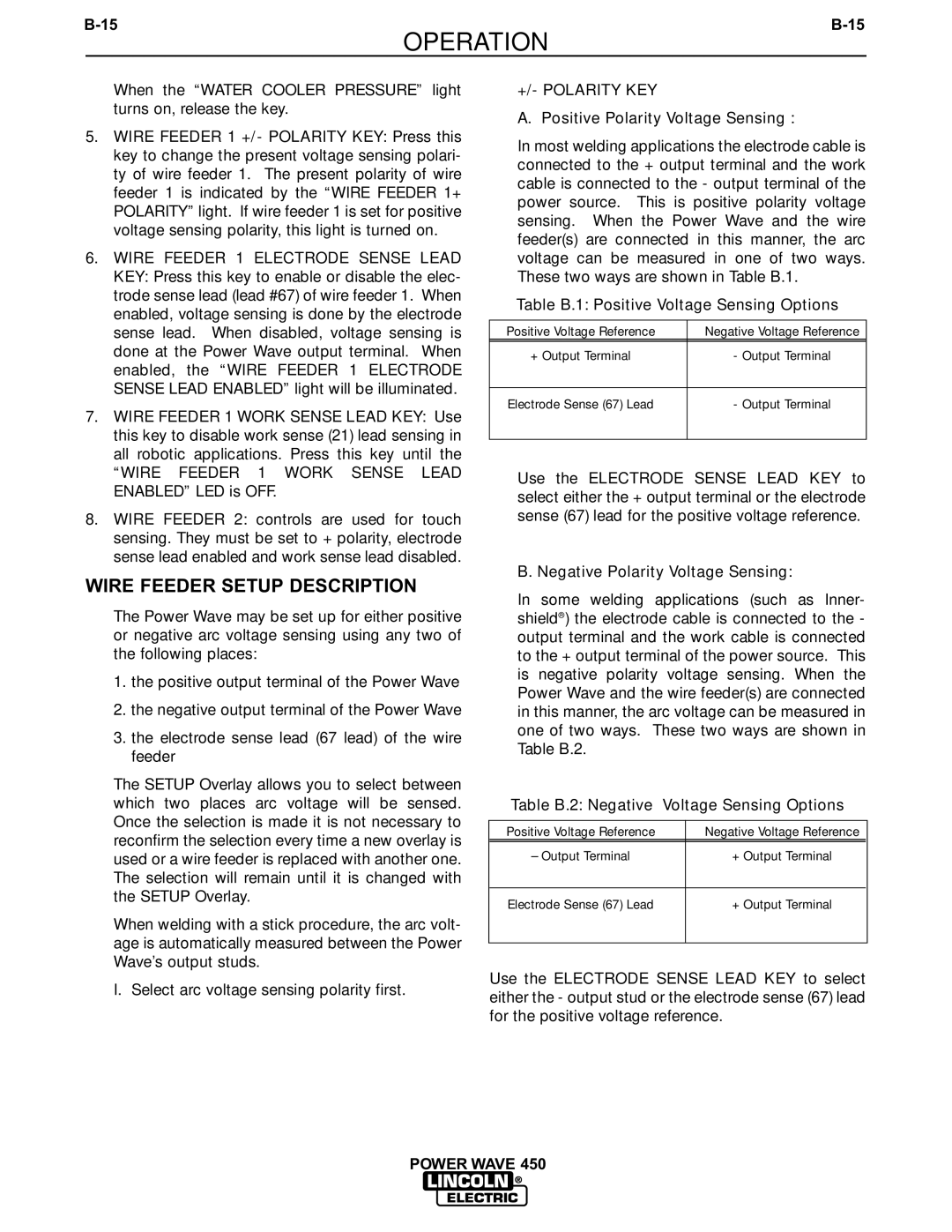

Table B.1: Positive Voltage Sensing Options

Positive Voltage Reference | Negative Voltage Reference |

|

|

+ Output Terminal | - Output Terminal |

|

|

Electrode Sense (67) Lead | - Output Terminal |

|

|

Use the ELECTRODE SENSE LEAD KEY to select either the + output terminal or the electrode sense (67) lead for the positive voltage reference.

B. Negative Polarity Voltage Sensing:

In some welding applications (such as Inner- shield®) the electrode cable is connected to the - output terminal and the work cable is connected to the + output terminal of the power source. This is negative polarity voltage sensing. When the Power Wave and the wire feeder(s) are connected in this manner, the arc voltage can be measured in one of two ways. These two ways are shown in Table B.2.

Table B.2: Negative Voltage Sensing Options

Positive Voltage Reference | Negative Voltage Reference |

|

|

– Output Terminal | + Output Terminal |

|

|

Electrode Sense (67) Lead | + Output Terminal |

|

|

I. Select arc voltage sensing polarity first.

Use the ELECTRODE SENSE LEAD KEY to select either the - output stud or the electrode sense (67) lead for the positive voltage reference.