INSTALLATION | ||

|

|

|

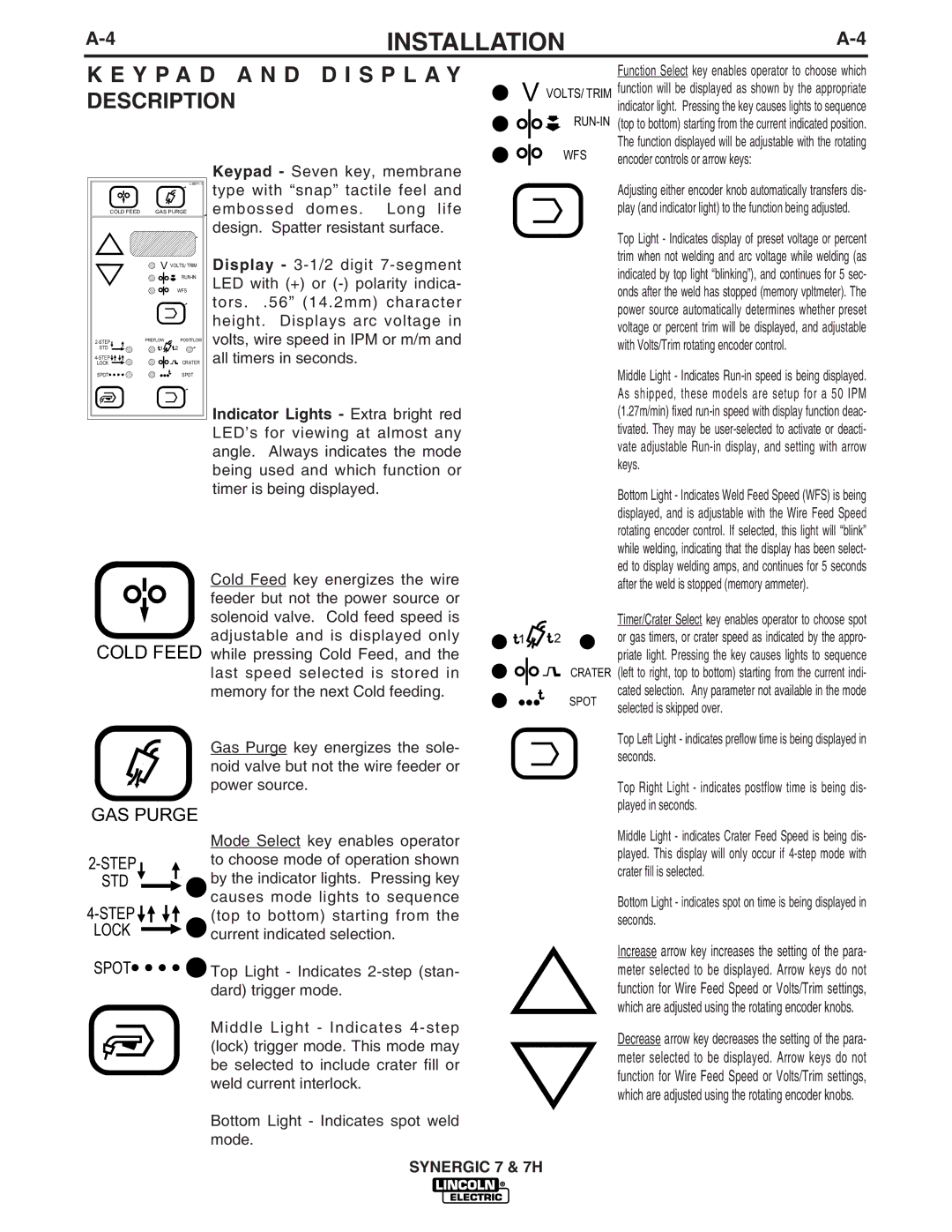

K E Y P A D A N D D I S P L A Y DESCRIPTION

V VOLTS/ TRIM

RUN-IN

WFS

Function Select key enables operator to choose which function will be displayed as shown by the appropriate indicator light. Pressing the key causes lights to sequence (top to bottom) starting from the current indicated position. The function displayed will be adjustable with the rotating encoder controls or arrow keys:

|

| |

COLD FEED | GAS PURGE | |

| V VOLTS/ TRIM | |

|

| |

|

| WFS |

PREFLOW | POSTFLOW | |

STD | 1 | 2 |

| CRATER | |

LOCK |

| |

SPOT |

| SPOT |

Keypad - Seven key, membrane type with “snap” tactile feel and embossed domes. Long life design. Spatter resistant surface.

Display -

Indicator Lights - Extra bright red LED’s for viewing at almost any angle. Always indicates the mode being used and which function or timer is being displayed.

Adjusting either encoder knob automatically transfers dis- play (and indicator light) to the function being adjusted.

Top Light - Indicates display of preset voltage or percent trim when not welding and arc voltage while welding (as indicated by top light “blinking”), and continues for 5 sec- onds after the weld has stopped (memory vpltmeter). The power source automatically determines whether preset voltage or percent trim will be displayed, and adjustable with Volts/Trim rotating encoder control.

Middle Light - Indicates

Bottom Light - Indicates Weld Feed Speed (WFS) is being displayed, and is adjustable with the Wire Feed Speed rotating encoder control. If selected, this light will “blink” while welding, indicating that the display has been select-

Cold Feed key energizes the wire

feeder but not the power source or

![]() solenoid valve. Cold feed speed is adjustable and is displayed only COLD FEED while pressing Cold Feed, and the last speed selected is stored in

solenoid valve. Cold feed speed is adjustable and is displayed only COLD FEED while pressing Cold Feed, and the last speed selected is stored in

memory for the next Cold feeding.

Gas Purge key energizes the sole- noid valve but not the wire feeder or power source.

GAS PURGE

![]()

![]()

![]() 1

1![]()

![]() 2

2

CRATER

SPOT

ed to display welding amps, and continues for 5 seconds after the weld is stopped (memory ammeter).

Timer/Crater Select key enables operator to choose spot or gas timers, or crater speed as indicated by the appro- priate light. Pressing the key causes lights to sequence (left to right, top to bottom) starting from the current indi- cated selection. Any parameter not available in the mode selected is skipped over.

Top Left Light - indicates preflow time is being displayed in seconds.

Top Right Light - indicates postflow time is being dis- played in seconds.

![]()

![]()

STD

![]()

![]()

![]()

![]()

LOCK

SPOT

Mode Select key enables operator to choose mode of operation shown by the indicator lights. Pressing key causes mode lights to sequence (top to bottom) starting from the current indicated selection.

Top Light - Indicates

Middle Light - indicates Crater Feed Speed is being dis- played. This display will only occur if

Bottom Light - indicates spot on time is being displayed in seconds.

Increase arrow key increases the setting of the para- meter selected to be displayed. Arrow keys do not function for Wire Feed Speed or Volts/Trim settings, which are adjusted using the rotating encoder knobs.

Middle Light - Indicates

Bottom Light - Indicates spot weld mode.

SYNERGIC 7 & 7H

Decrease arrow key decreases the setting of the para- meter selected to be displayed. Arrow keys do not function for Wire Feed Speed or Volts/Trim settings, which are adjusted using the rotating encoder knobs.