TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

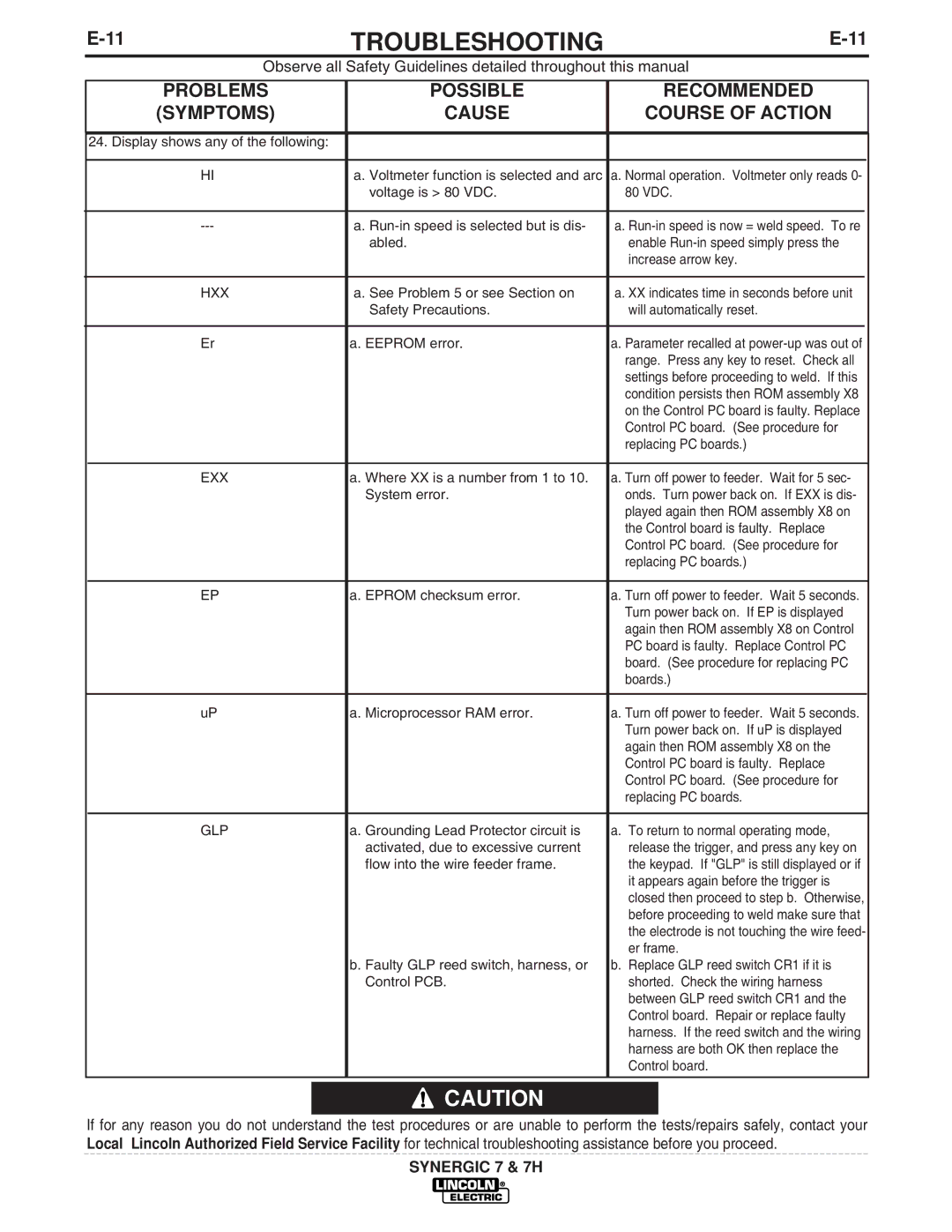

24. Display shows any of the following: |

|

|

|

|

|

| |

HI | a. Voltmeter function is selected and arc | a. Normal operation. Voltmeter only reads 0- | |

| voltage is > 80 VDC. | 80 VDC. | |

|

|

|

|

a. | a. | ||

| abled. | enable | |

|

| increase arrow key. | |

|

|

|

|

HXX | a. See Problem 5 or see Section on | a. XX indicates time in seconds before unit | |

| Safety Precautions. | will automatically reset. | |

|

|

|

|

Er | a. EEPROM error. | a. Parameter recalled at | |

|

| range. Press any key to reset. Check all | |

|

| settings before proceeding to weld. If this | |

|

| condition persists then ROM assembly X8 | |

|

| on the Control PC board is faulty. Replace | |

|

| Control PC board. (See procedure for | |

|

| replacing PC boards.) | |

|

|

| |

EXX | a. Where XX is a number from 1 to 10. | a. Turn off power to feeder. Wait for 5 sec- | |

| System error. | onds. Turn power back on. If EXX is dis- | |

|

| played again then ROM assembly X8 on | |

|

| the Control board is faulty. Replace | |

|

| Control PC board. (See procedure for | |

|

| replacing PC boards.) | |

|

|

| |

EP | a. EPROM checksum error. | a. Turn off power to feeder. Wait 5 seconds. | |

|

| Turn power back on. If EP is displayed | |

|

| again then ROM assembly X8 on Control | |

|

| PC board is faulty. Replace Control PC | |

|

| board. (See procedure for replacing PC | |

|

| boards.) | |

|

|

| |

uP | a. Microprocessor RAM error. | a. Turn off power to feeder. Wait 5 seconds. | |

|

| Turn power back on. If uP is displayed | |

|

| again then ROM assembly X8 on the | |

|

| Control PC board is faulty. Replace | |

|

| Control PC board. (See procedure for | |

|

| replacing PC boards. | |

|

|

| |

GLP | a. Grounding Lead Protector circuit is | a. To return to normal operating mode, | |

| activated, due to excessive current | release the trigger, and press any key on | |

| flow into the wire feeder frame. | the keypad. If "GLP" is still displayed or if | |

|

| it appears again before the trigger is | |

|

| closed then proceed to step b. Otherwise, | |

|

| before proceeding to weld make sure that | |

|

| the electrode is not touching the wire feed- | |

|

| er frame. | |

| b. Faulty GLP reed switch, harness, or | b. Replace GLP reed switch CR1 if it is | |

| Control PCB. | shorted. Check the wiring harness | |

|

| between GLP reed switch CR1 and the | |

|

| Control board. Repair or replace faulty | |

|

| harness. If the reed switch and the wiring | |

|

| harness are both OK then replace the | |

|

| Control board. | |

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

SYNERGIC 7 & 7H