INSTALLATION | ||

|

|

|

GENERAL DESCRIPTION

The Synergic 7 is a semiautomatic constant speed wire feeder designed specifically for use with the Invertec Power Wave type power sources. A serial communication link is supplied through the control cable of the Synergic 7 enabling information to be shared between the power source and wire feeder. The Synergic 7 comes factory equipped with a gas solenoid valve with gas fittings and standard Lincoln gun connector. These models includes a

The unit has 3 operating modes: 2-step trigger, 4-step trig-

ger and spot. Three functions can be selected: Volts or Trim Preset/arc (memory) voltmeter,

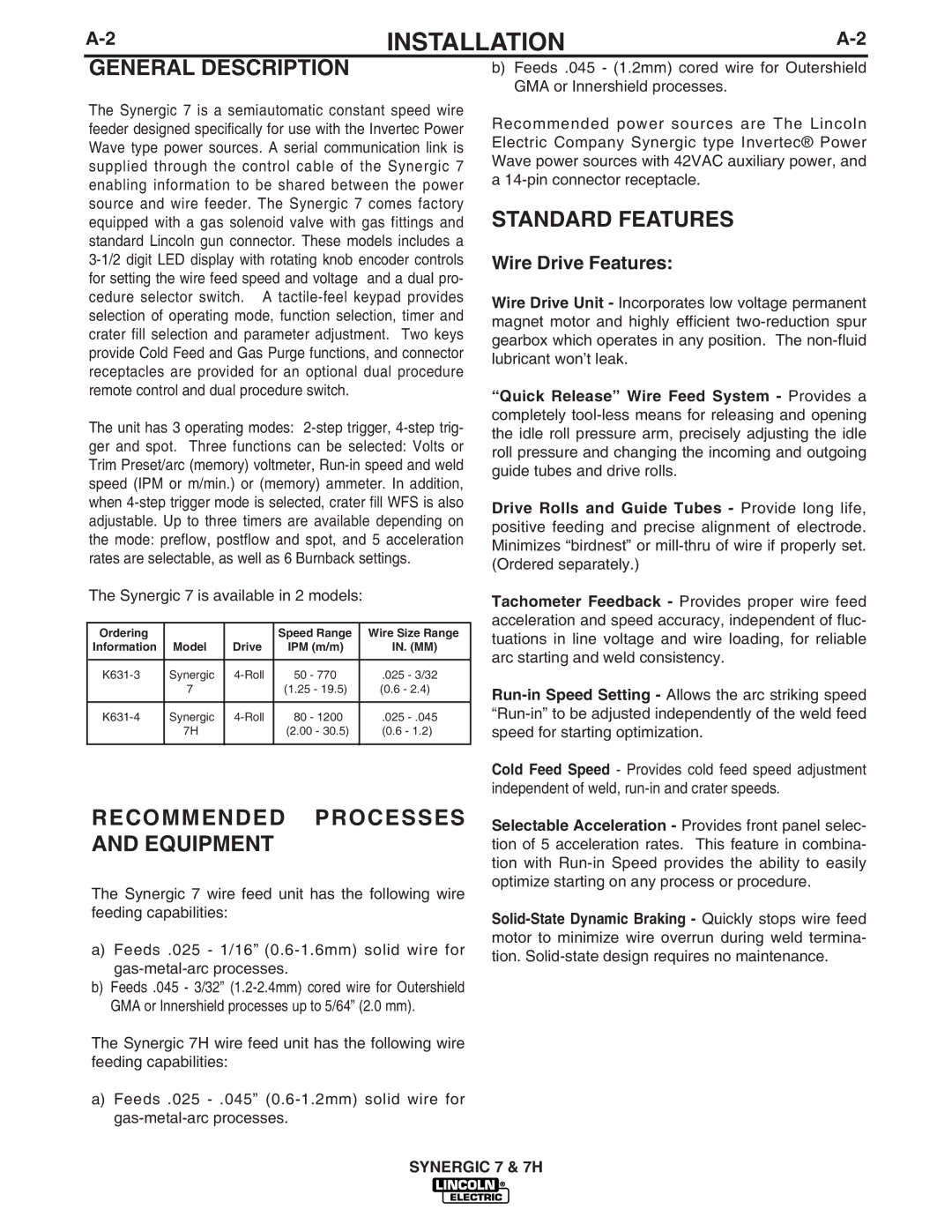

The Synergic 7 is available in 2 models:

Ordering |

|

| Speed Range | Wire Size Range |

Information | Model | Drive | IPM (m/m) | IN. (MM) |

|

|

|

|

|

Synergic | 50 - 770 | .025 - 3/32 | ||

| 7 |

| (1.25 - 19.5) | (0.6 - 2.4) |

|

|

|

|

|

Synergic | 80 - 1200 | .025 | ||

| 7H |

| (2.00 - 30.5) | (0.6 - 1.2) |

|

|

|

|

|

RECOMMENDED PROCESSES AND EQUIPMENT

The Synergic 7 wire feed unit has the following wire feeding capabilities:

a)Feeds .025 - 1/16”

b)Feeds .045 - 3/32”

The Synergic 7H wire feed unit has the following wire feeding capabilities:

a)Feeds .025

b)Feeds .045 - (1.2mm) cored wire for Outershield GMA or Innershield processes.

Recommended power sources are The Lincoln Electric Company Synergic type Invertec® Power Wave power sources with 42VAC auxiliary power, and a

STANDARD FEATURES

Wire Drive Features:

Wire Drive Unit - Incorporates low voltage permanent magnet motor and highly efficient

“Quick Release” Wire Feed System - Provides a completely

Drive Rolls and Guide Tubes - Provide long life, positive feeding and precise alignment of electrode. Minimizes “birdnest” or

Tachometer Feedback - Provides proper wire feed acceleration and speed accuracy, independent of fluc- tuations in line voltage and wire loading, for reliable arc starting and weld consistency.

Cold Feed Speed - Provides cold feed speed adjustment independent of weld,

Selectable Acceleration - Provides front panel selec- tion of 5 acceleration rates. This feature in combina- tion with

SYNERGIC 7 & 7H